Online monitoring method for water content and pollution degree of lubricating oil of rolling mill

A technology of moisture content and pollution degree, which is applied in the direction of length measuring device, metal rolling, metal rolling, etc., can solve the problems of changing measurement results, complex factors of oil dielectric constant change, hindering the application of online monitoring technology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

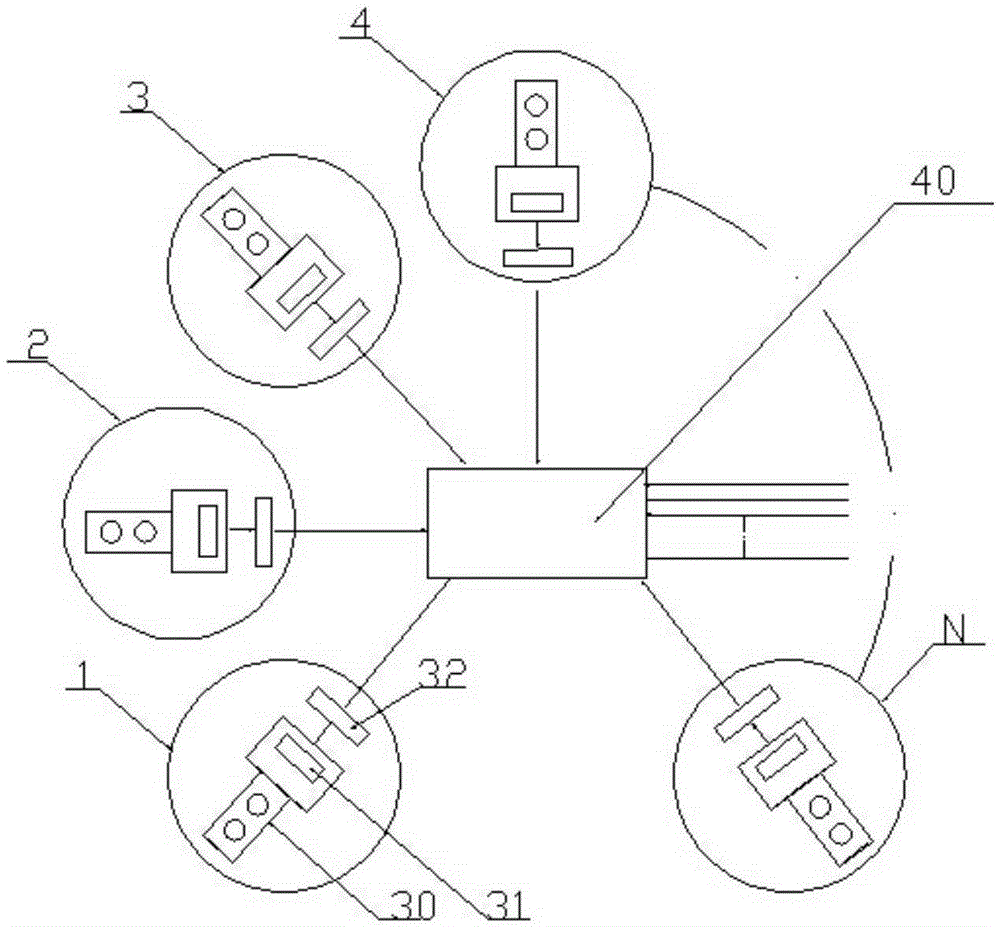

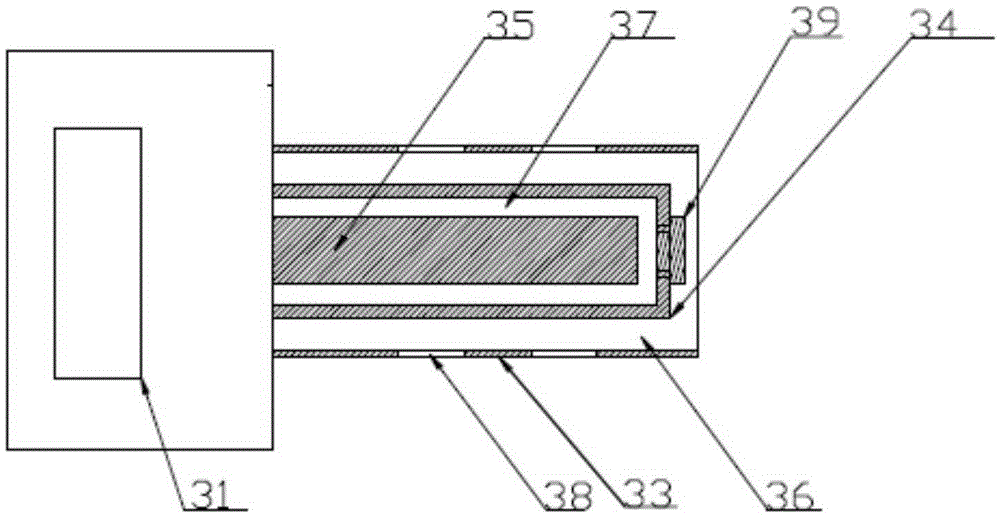

[0037] combine figure 1 , figure 2 , this embodiment is an example with multi-point decentralized remote monitoring and centralized control. There are multiple lubrication units that need to be monitored in a branch of the steel mill. Take the rolling mill workshop as an example, because the work requires that each rolling mill and oil tank must be monitored. monitor. An on-line monitoring device for moisture content and pollution degree of rolling mill lubricating oil in this embodiment includes an oil tank and a rolling mill lubrication pipeline with a total of 9 lubrication monitoring points. As far as the present embodiment is concerned, N=9, figure 1 The marks 1, 2, 3, 4, and N all refer to the lubrication monitoring module, so there are 9 lubrication monitoring modules to monitor the lubrication branch and the oil tank of the rolling mill, wherein: the monitoring module of each lubrication monitoring point includes capacitance sensor probe electrodes 30 , capacitive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com