Comprehensive test platform for fluorescence microscope objective

A microscopic objective lens and comprehensive testing technology, which is applied in the field of optical detection, can solve the problems of low efficiency, difficult assembly and test, and can not truly reflect the comprehensive imaging energy of the microscopic objective lens, and achieve the effect of high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings of the description.

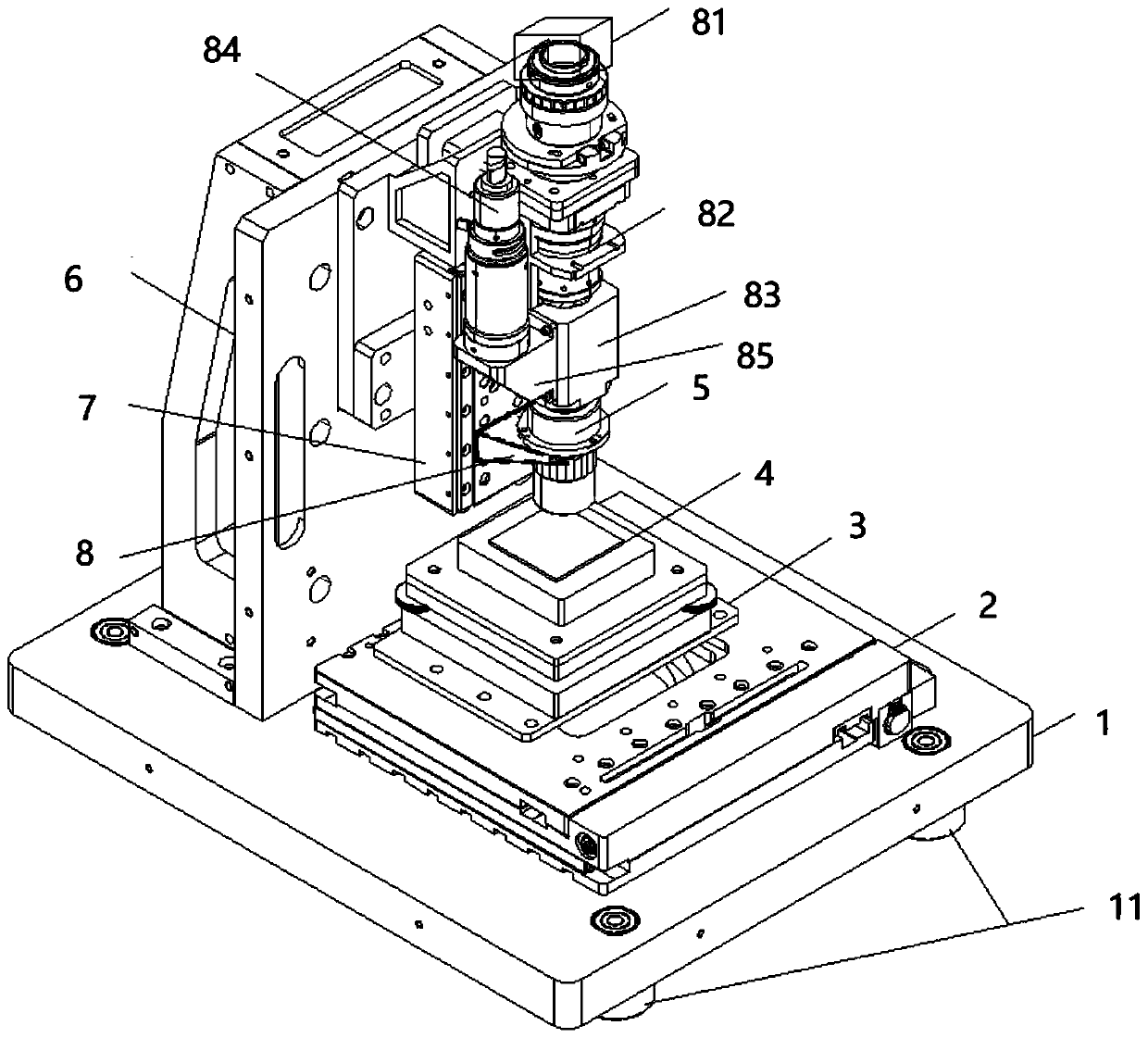

[0016] like Figure 1~3 As shown, the fluorescent microscope objective lens comprehensive test platform of the present invention includes a base plate 1, and the four corners of the base plate 1 are respectively provided with supporting feet 11, and the supporting feet 11 are connected with the base plate 1 by threads, and the depth of extending into the base plate 1 can be adjusted. Thereby, the overall level adjustment of the bottom plate 1 is realized.

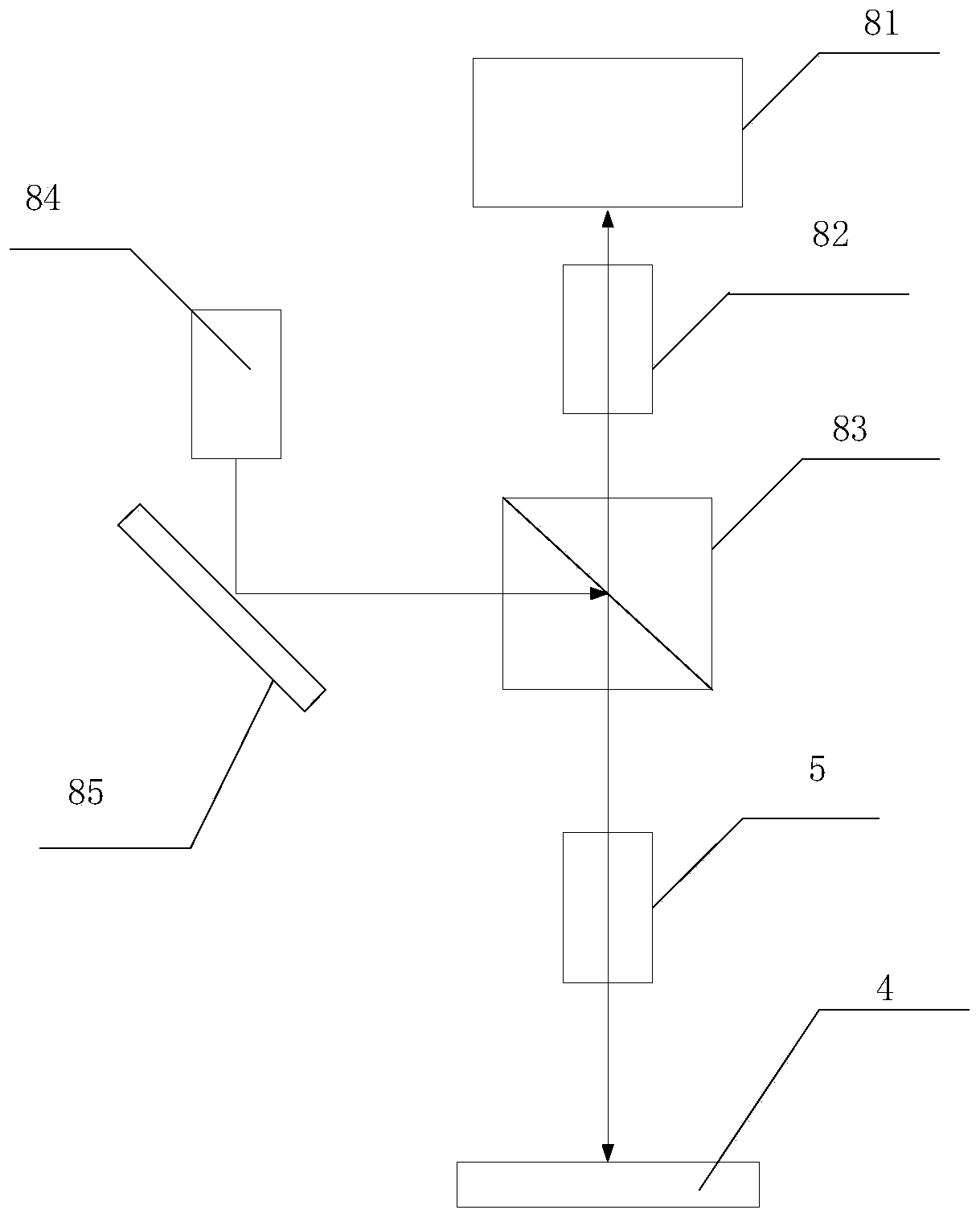

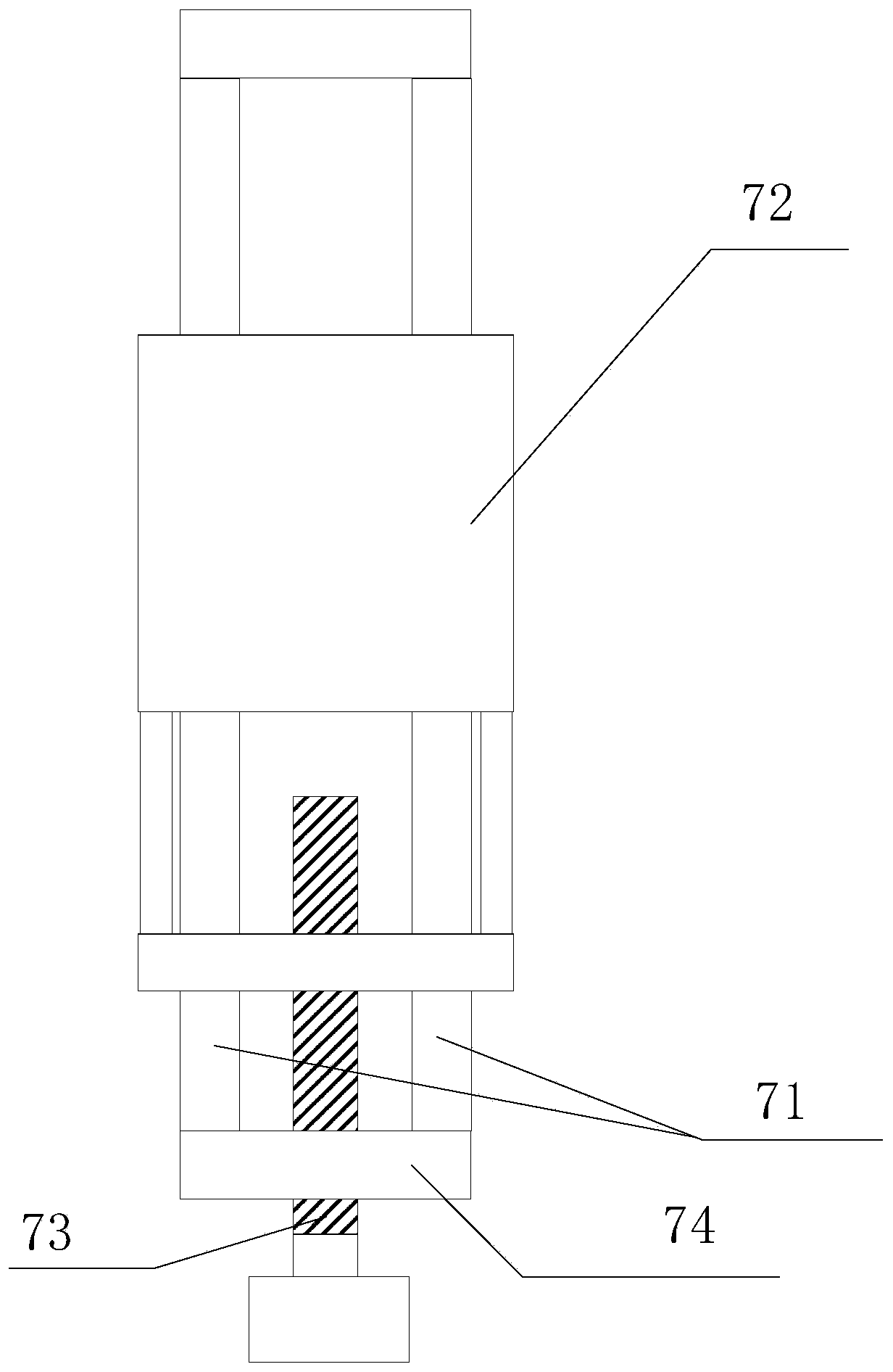

[0017] The base plate 1 is provided with a horizontal adjustment device and a vertical fixing mechanism. Wherein, the level adjustment device includes a two-dimensional translation platform 2 and a two-dimensional tilting platform 3 stacked in sequence. The two-dimensional translation stage 2 can perform two-dimensional movement in the horizontal direction. The two-dimensional tilt table 3 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com