Method for measuring rotating speed and friction power consumption of centrifugal machine

A technology for centrifuges and power consumption, which is applied to devices using electrical/magnetic methods, measuring devices, and testing of machines/structural components. Easy to modify or expand, short inspection time, easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

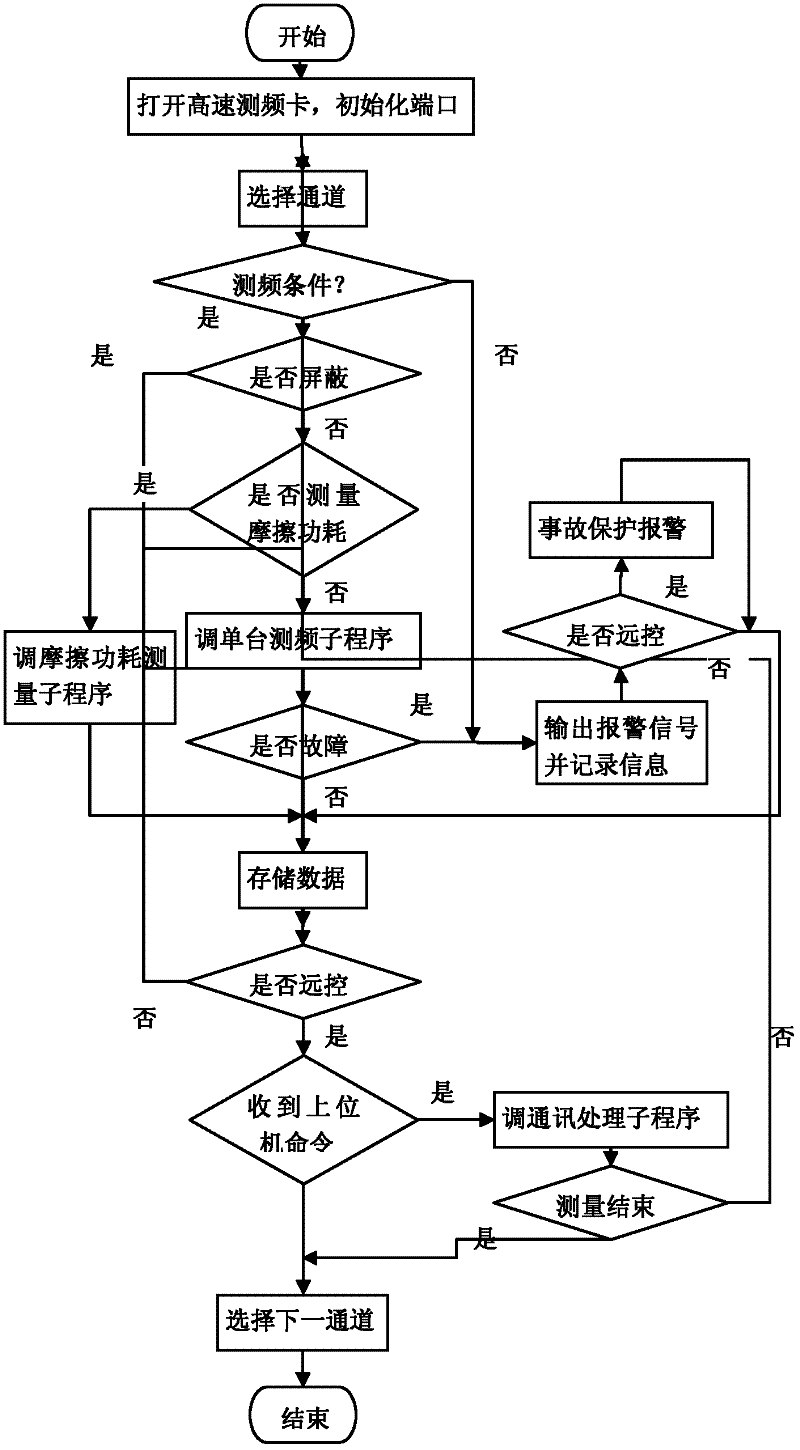

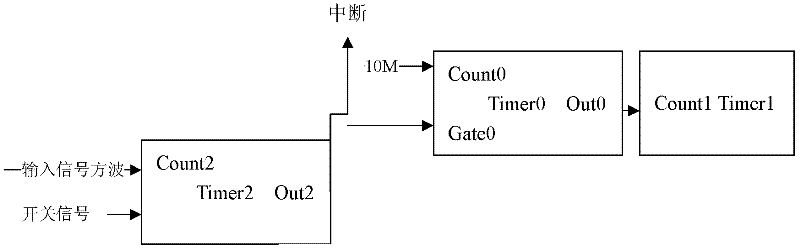

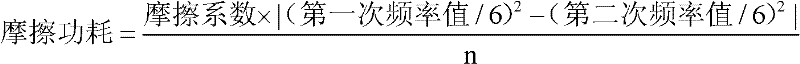

[0035] The present invention is described in detail below in conjunction with accompanying drawing, as figure 1 , figure 2 Shown:

[0036] The method for measuring the rotating speed of the centrifuge and the frictional power consumption specifically comprises the following steps:

[0037] 1] Initialize

[0038] Turn on the high-speed frequency measurement card, initialize the hardware port, and restore the speed and friction power measurement device to the initial state. The initial state is that all signal lights are off and there is no fault alarm; then all centrifuges in the monitored section are monitored. Inspection, to determine the status of the centrifuge corresponding to each channel, including normal centrifuge, centrifuge out of step, centrifuge damage and centrifuge not installed, and perform calibration, the channel not installed centrifuge and confirm that the centrifuge is damaged when shielding the channel;

[0039] Specifically, it can be operated as fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com