Generator with single turn wave winding, wind turbine and method for determining the thickness of the slot insulation of a generator

A generator, slot insulation technology, applied in the shape/style/structure of wind turbines, winding insulation, motors, etc., can solve the problems of reducing efficiency, reducing output torque, difficult cooling, etc., to eliminate unnecessary volume , the effect of enhancing cooling and increasing the filling factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

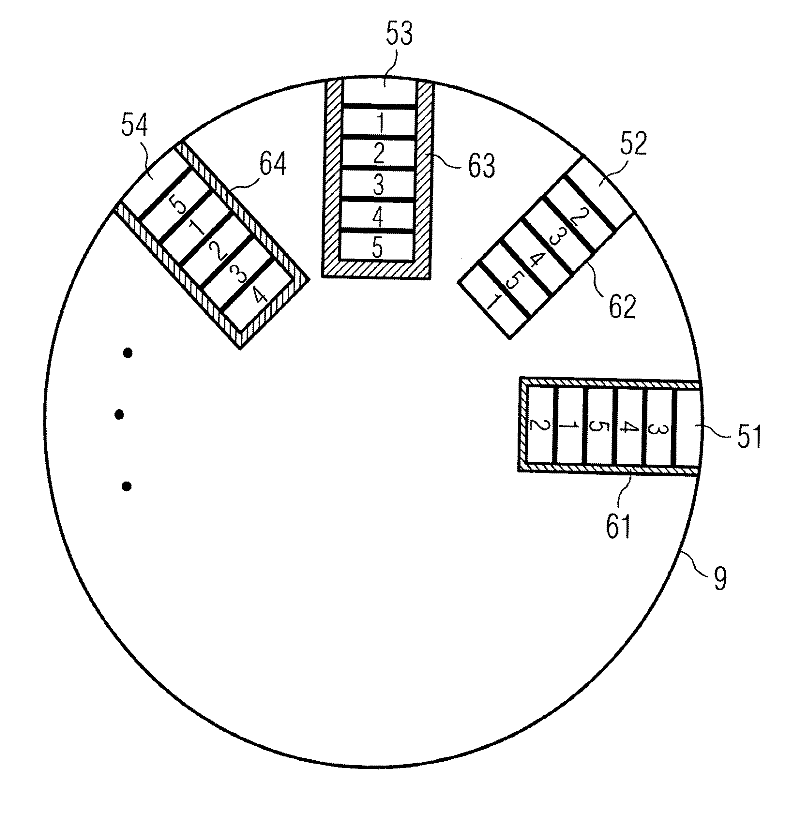

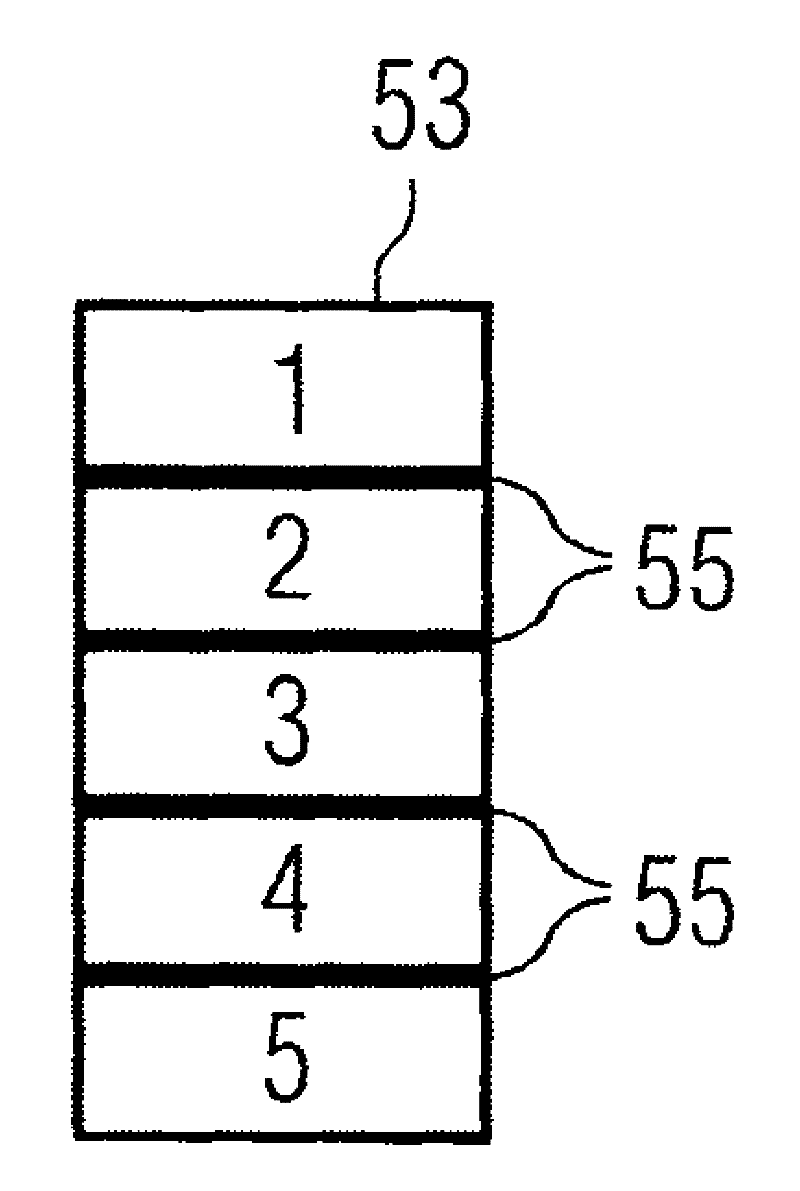

[0035] will now refer to Figures 1 to 7 Embodiments of the present invention will be described.

[0036] figure 1 A wind turbine 71 is shown schematically. The wind turbine 71 comprises a tower 72 , a nacelle 73 and a hub 74 . The nacelle 73 is located on top of the tower 72 . Hub 74 includes a plurality of wind turbine blades 75 . Hub 74 is mounted to nacelle 73 . Furthermore, the hub 74 is pivotally mounted such that it can rotate about an axis of rotation 79 . The generator 76 is located inside the nacelle 73 . Wind turbine 71 is a direct drive wind turbine.

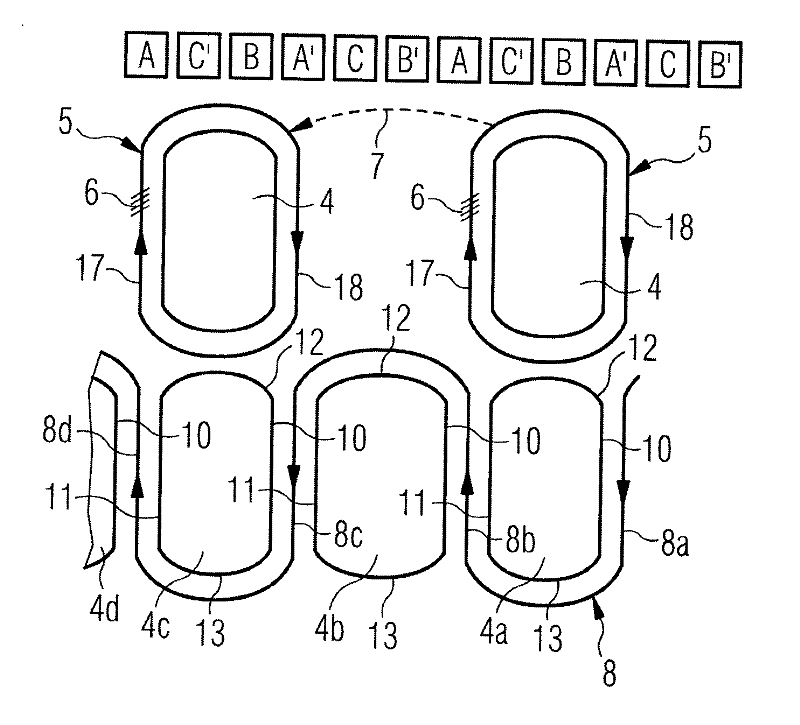

[0037] figure 2 Schematically showing a comparative illustration of multi-turn and single-turn wave windings for one phase and four poles. figure 2 The upper part of shows a distributed winding where for a 3-phase motor (phases A, B and C) the slots are equal to 1 for each pole and phase. A, B and C correspond to the outbound direction of the phase, and A', B' and C' correspond to the return direction of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com