Electric carrier wave lighting control system

A power carrier and control system technology, applied in distribution line transmission system, lamp circuit layout, electric light source, etc., can solve the problems of cumbersome investigation, low efficiency, time-consuming and laborious, etc., to increase economic benefits and management quality, improve The effect of the level of automation management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

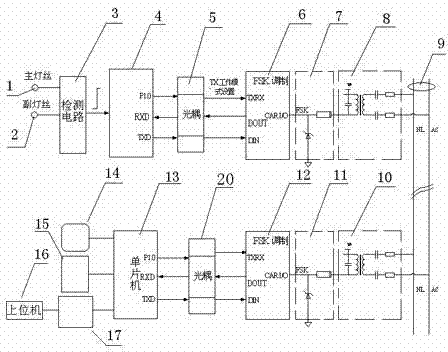

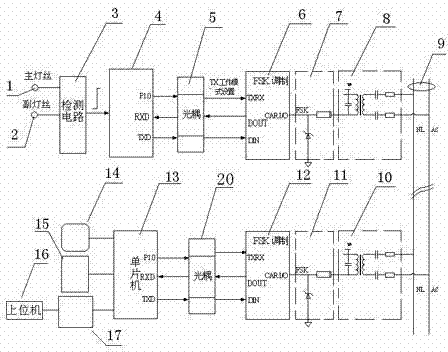

[0019] Such as figure 1 As shown, this is an implementation mode suitable for a single railway signal light or multiple railway signal lights powered by the same power line.

[0020] It includes at least an outdoor unit and an indoor unit; a detection circuit 3 is electrically connected to the main filament 1 and the auxiliary filament 2 of the outdoor unit, and the detection circuit 3 is used to detect the working status of the main filament 1 and the auxiliary filament 2, and the main filament 1 and the auxiliary filament 2 are connected to each other. The working state information of auxiliary filament 2 is provided to the outdoor unit single-chip microcomputer 4, when the main filament 1 is working and the auxiliary filament 2 is on standby, the main filament 1 is working normally, and the outdoor unit single-chip microcomputer 4 electrically connected with the detection circuit 3 obtains normal filament state information; When the filament 1 is working and the sub-filamen...

Embodiment 2

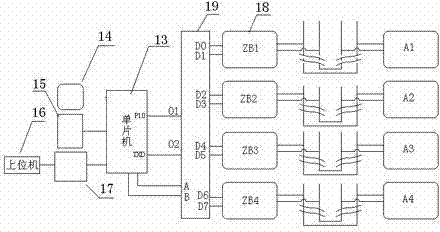

[0034] Such as figure 2 As shown, this is an implementation mode suitable for a single railway signal lamp or a railway signal lamp powered by multiple power lines.

[0035] Since embodiment 2 has the same circuit structure as embodiment 1, only the interface of the indoor unit adopts a plurality of power carrier circuits 18, and the plurality of power carrier circuits 18 are respectively electrically connected to the power line 9, so the following only applies to different indoor units. The machine interface circuit part is described.

[0036] Outdoor units A1, A2, A3, A4 are connected to different power lines 9, and the outdoor units A1, A2, A3, A4 have the same circuit structure, and the circuit is the same as figure 1 The same as in the description, it is used to detect the status of the main filament 1 and the sub-filament 2 of the railway signal lamp in different power line circuits, and transmit the status information of the main filament 1 and the sub-filament 2 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com