Boiler water quality comprehensive monitoring method, system and equipment based on Internet of Things

A technology of comprehensive monitoring and Internet of Things, applied in the field of comprehensive monitoring of boiler water quality based on Internet of Things, can solve the problems of insufficient scientific and reasonable design, no boiler monitoring, no boiler blowdown rate, reasonable design of cleaning cycle, etc., and achieve the operation and maintenance process. Scientific and reasonable, the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

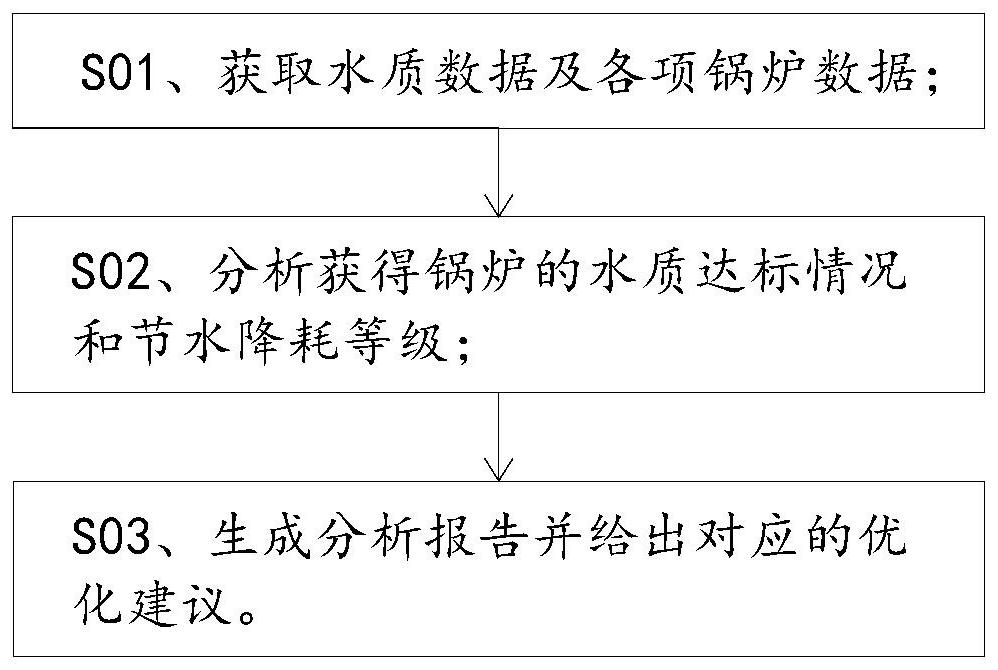

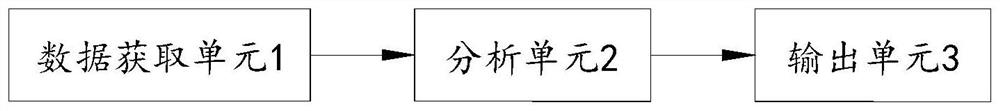

[0059] like figure 1 As shown, a method for comprehensive monitoring of boiler water quality based on the Internet of Things described in this disclosure includes the following steps:

[0060] S01. Obtain water quality data and various boiler data;

[0061] S02. According to the water quality data and boiler data, analyze and obtain the water quality compliance of the boiler and the level of water saving and consumption reduction;

[0062] S03. Generate an analysis report and give corresponding optimization suggestions according to the obtained water quality standards and water saving and consumption reduction grades.

[0063] The disclosure can realize automatic analysis and monitoring of water saving and consumption reduction indicators such as the water quality of the boiler as well as the blowdown rate and scaling rate, and can further analyze and obtain the water quality compliance of the boiler and the level of water saving and consumption reduction, so that the user ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com