A fast spiral filter

A filter and spiral technology, which is applied in the field of fast spiral filter, can solve the problems of low filtration efficiency and achieve the effects of improved filtration efficiency, convenient operation and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

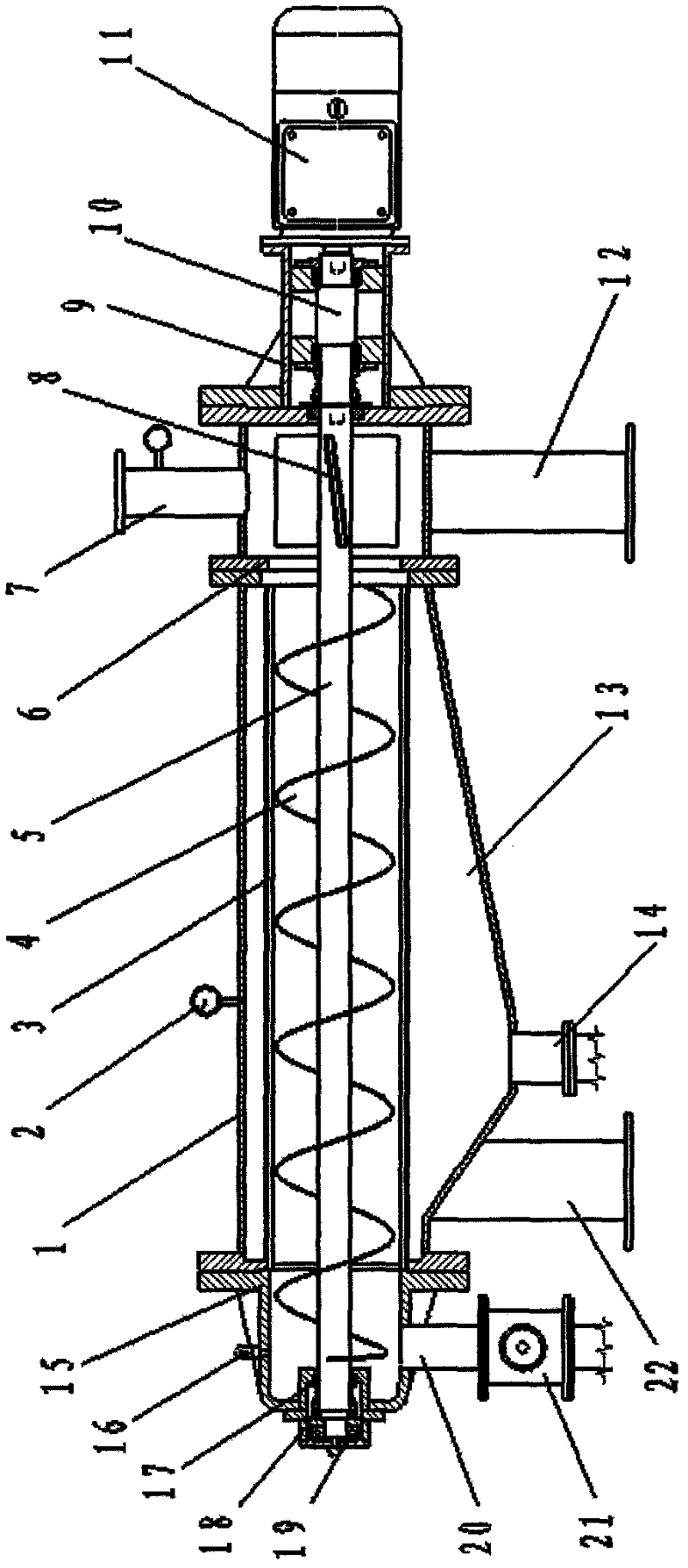

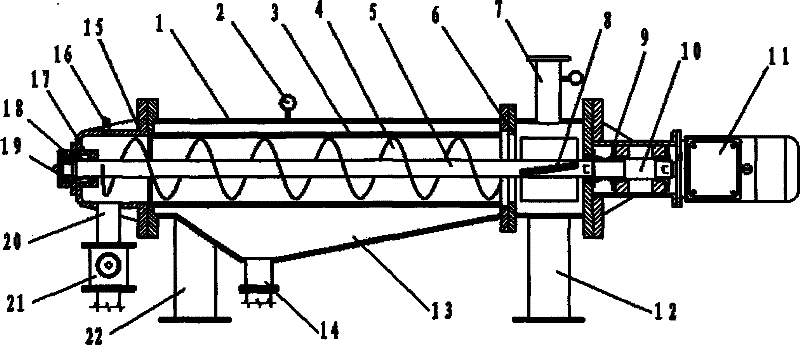

[0012] Example 1: please combine figure 1 As shown, the present invention provides a fast screw filter, the filter is provided with a main body 1 connected to the feed cylinder 6 and a rear end cover 15 fastened by flange connection bolts, the main body 1 is provided with a flange and a liquid collection tank 13 The set flange connection, the liquid collecting tank 13 is provided with the liquid outlet hole 14 to connect the external pipe, the rear end of the liquid collecting tank 13 is connected with the rear outrigger 22, the material used is carbon structural steel or stainless steel and formed by welding, and the pressure gauge 2 is installed On the main body 1, the main body 1 is equipped with a filter screen skeleton 3 and an installed filter screen or filter cloth. The feeding cylinder 6 and the drive shaft sleeve 9 are connected by a flange, and the feeding hole 7 and the pressure gauge are installed on it. The bottom of the feeding cylinder 6 is connected with the fr...

Embodiment 2

[0013] Example 2: please combine figure 1 As shown, a kind of fast spiral filter begins to filter, and the screw shaft 5 connected by the motor 11 rotates through the transmission shaft 10, and the material enters the feeding cylinder 6 through the pipeline of the feed hole 7, and the material guide piece 8 of the screw shaft 5 is turned. The animal material enters the spiral sheet 4 and enters the filter chamber. The filter screen and filter cloth installed on the filter screen skeleton 3 and the spiral sheet 4 have a gap of 3-5 mm to form a filter cake layer, and the solid particles are pushed by the spiral sheet to the rear end cover 15 Inside, the filtrate passes through the filter screen and filter cloth installed by the filter screen frame 3 and flows to the sump 13, and is discharged from the pipeline connected with the liquid outlet hole 14, and the filter cake enters the rear end cover 15, and a discharge hole 20 and a control valve are provided. 21. The control valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com