A Rapid Measuring System of Filament Width

A measuring system and blade shred technology, which is applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of unwrapped shred width detection and monitoring, poor test result stability, and high labor intensity of surveyors, so as to reduce mobility Components, high measurement accuracy and stability, and the effect of reducing artificial interference factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

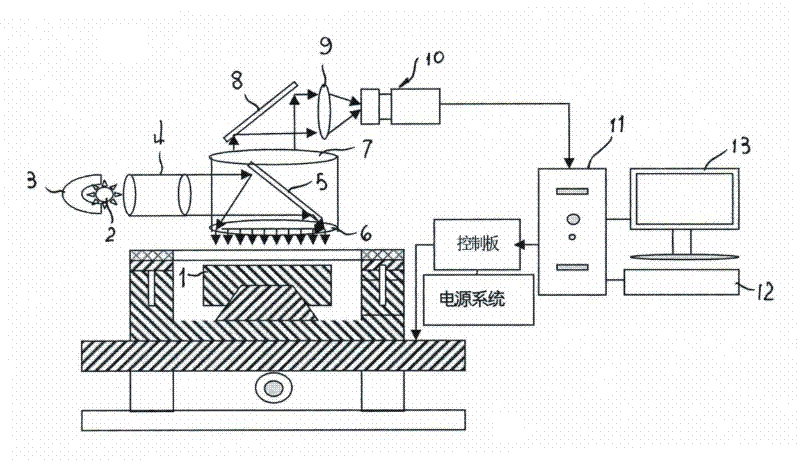

[0024] figure 1 Among them, the lighting (optical) system mainly consists of LED light source, power supply and ellipsoidal mirror, which has the characteristics of large lighting area, high lighting intensity and good lighting uniformity, and is the basis for improving the imaging quality and measurement accuracy of leaf filaments. One of the keys of the present invention. There is an illumination system above the stage 1: the LED light source 2 is set at the focal point of the ellipsoidal mirror 3 (the LED light source is placed at the focal point of the ellipsoidal mirror, and the light emitted by the LED becomes quasi-parallel incident light through the ellipsoidal mirror, and the outgoing light A high-intensity and uniform lighting source is formed through the lighting optical system, which is the basis for improving the imaging quality and measurement accuracy of the leaf filament), and a parallel beam channel 4 and a half-mirror 5 are arranged in sequence in front of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com