Comprehensive test sample rod for double-shaft tilting in-situ force and electric property of transmission electron microscope

A biaxial tilting, transmission electron microscope technology, applied in the direction of applying stable tension/pressure to test the strength of materials, components of electrical measuring instruments, circuits, etc. In-situ deformation dynamic research and other issues to achieve the effect of shortening the length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

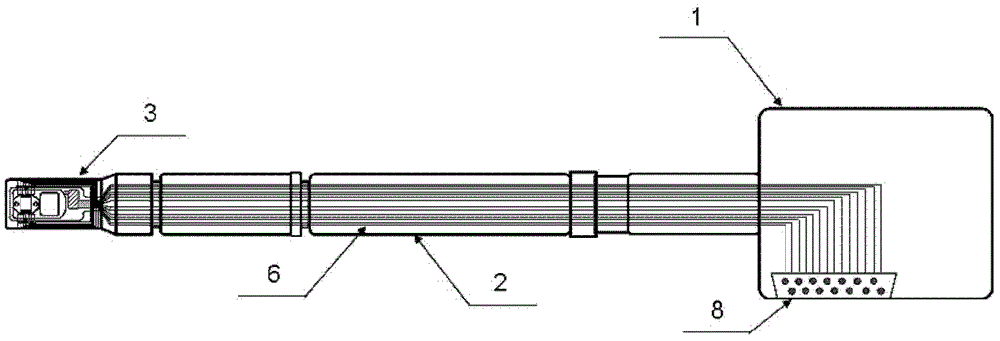

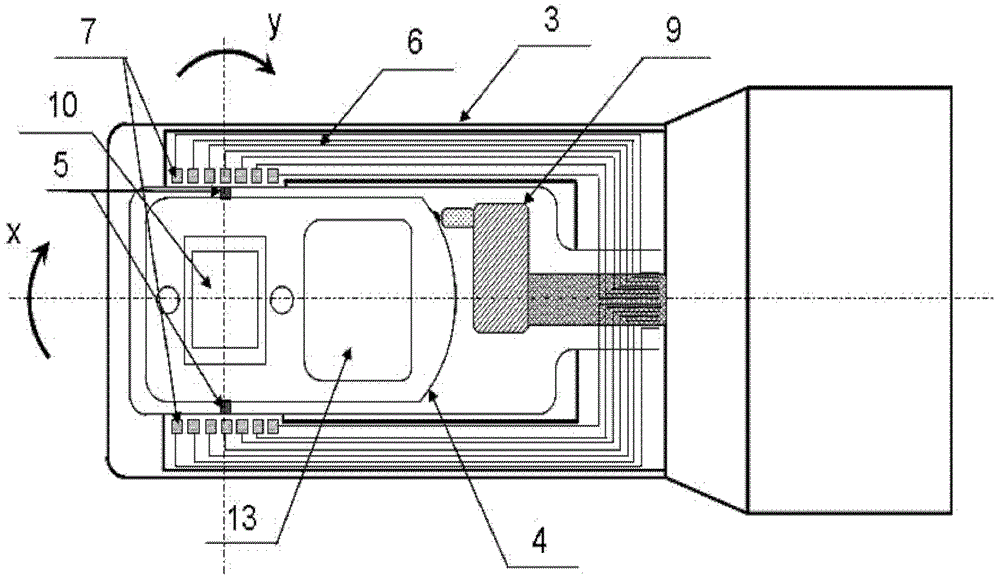

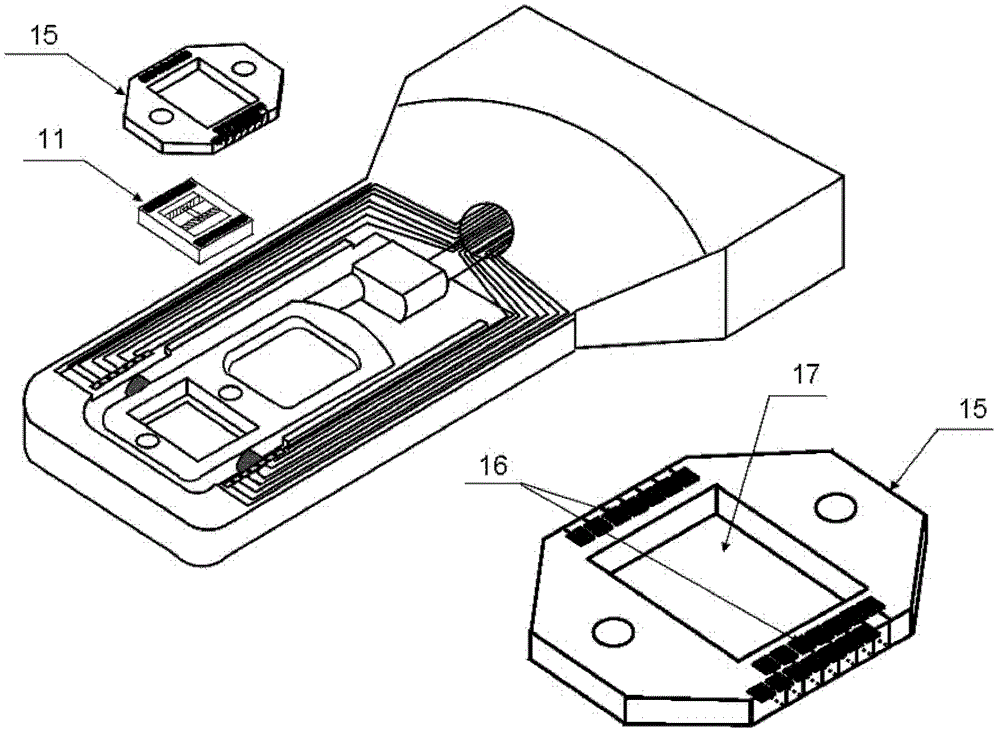

[0034] like figure 1 , as shown in 2, the in-situ force and electrical performance comprehensive test sample rod with biaxial tilting for transmission electron microscopy mainly includes a handle 1, a sample rod 2, a front end 3 of the sample head, and a sensor carrier 4 passes through the front end 3 of the sample head. The two inner support shafts 5 are fixed on the front end 3 of the sample head, tilt around the support shaft 5 in a plane perpendicular to the sample head (that is, rotate around the Y axis, ±30°), and the walls on both sides of the front end 3 of the sample head On the top, the wires I 6 introduced from the outside of the electron microscope through the sample rod 2 are symmetrically distributed, and are connected to the queue electrodes I 7 distributed on the two side walls of the front end 3 of the sample head, and the other end of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com