Elastic control piercing explosion protection device

A technology of flexible control and explosion-proof devices, which is applied in the direction of electrical components, circuits, battery pack components, etc., can solve the problems of fatality, discount, and inability to guarantee the safety of users, and achieve the effects of reducing noise, ensuring safety, and improving the ability to resist changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

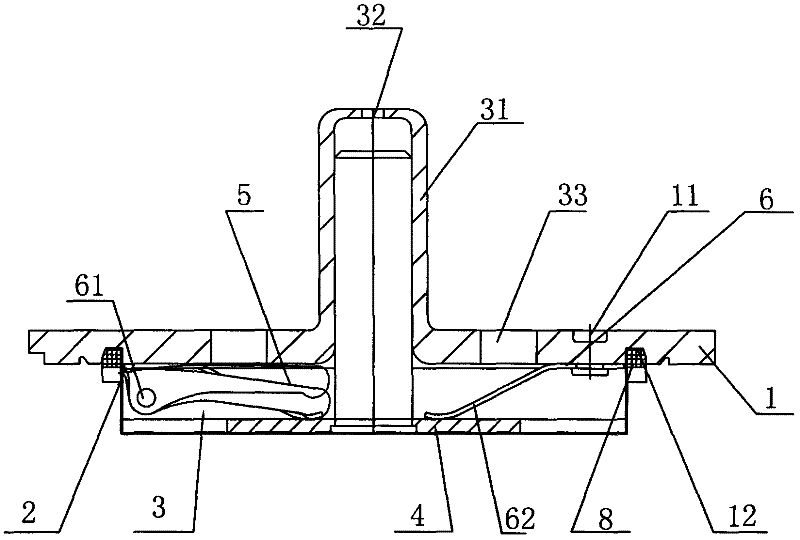

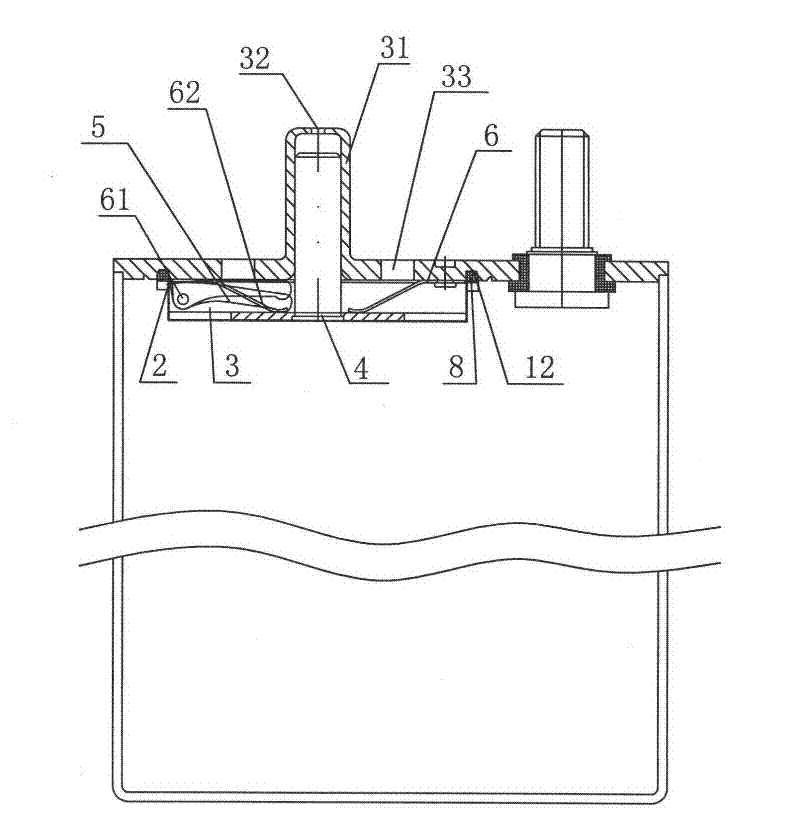

[0024] An elastic control piercing type explosion-proof device, comprising a battery cover 1, an explosion-proof film 2, an explosion-proof cavity 3 is formed between the battery cover 1 and the explosion-proof film 2, and a guide rod push plate 4, a lever type Bayonet 5 and elastic piece 6, the explosion-proof chamber 3 is provided with guide pipe 31 and vent holes 32, 33 respectively, guide pipe 31 cooperates with guide rod push plate 4, elastic piece 6 is provided with knife seat 61 and elastic claw 62, the lever bayonet 5 is hinged on the knife seat 61, the tip of the lever bayonet 5 is in contact with the explosion-proof film 2, the other end is corresponding to the guide rod push plate 4, and the free ends of the elastic claws 62 are respectively connected to the guide rod push plate In contact with each other, the guide pipe 31 and the vent holes 32, 33 are arranged on the battery cover 1, the battery cover 1 is provided with a ring groove 12, and the ring groove 12 is p...

specific Embodiment approach 2

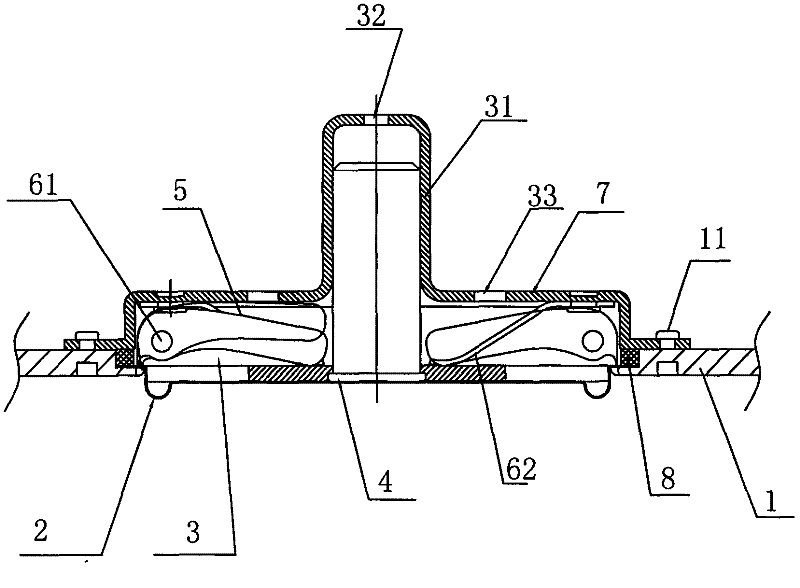

[0026] To further improve the explosion-proof structure of Embodiment 1, a top cover 7 is provided on the battery cover 1, and the top cover 7 is pressed on the battery cover 1 through riveting points 11, and an explosion-proof cavity is formed between the top cover 7 and the explosion-proof film 2 3. A guide rod push plate 4 and a lever-type bayonet 5 are provided in the explosion-proof chamber 3. The lever-type bayonet 5 is hinged on the top cover 7. The tip of the lever-type bayonet 5 is in contact with the explosion-proof film 2, and the other end is pushed with the guide rod. Corresponding to the plate 4, a four-claw shrapnel 6 is provided between the top cover 7 and the guide rod push plate 4, and the top cover 7 is provided with a guide tube 31 that is matched with the guide rod push plate 4. Through holes 32 and 33, a sealing ring 8 is provided between the top cover 7 and the battery cover 1, and the elastic sheet 6 is riveted on the top cover 7, and the top cover 7 can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com