Device that moves glass items onto a conveyor belt

A technology of conveyor belt and rotary drive device, which is applied in glass forming, glass blowing, glass manufacturing equipment, etc., can solve the problems of complex device design and achieve the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

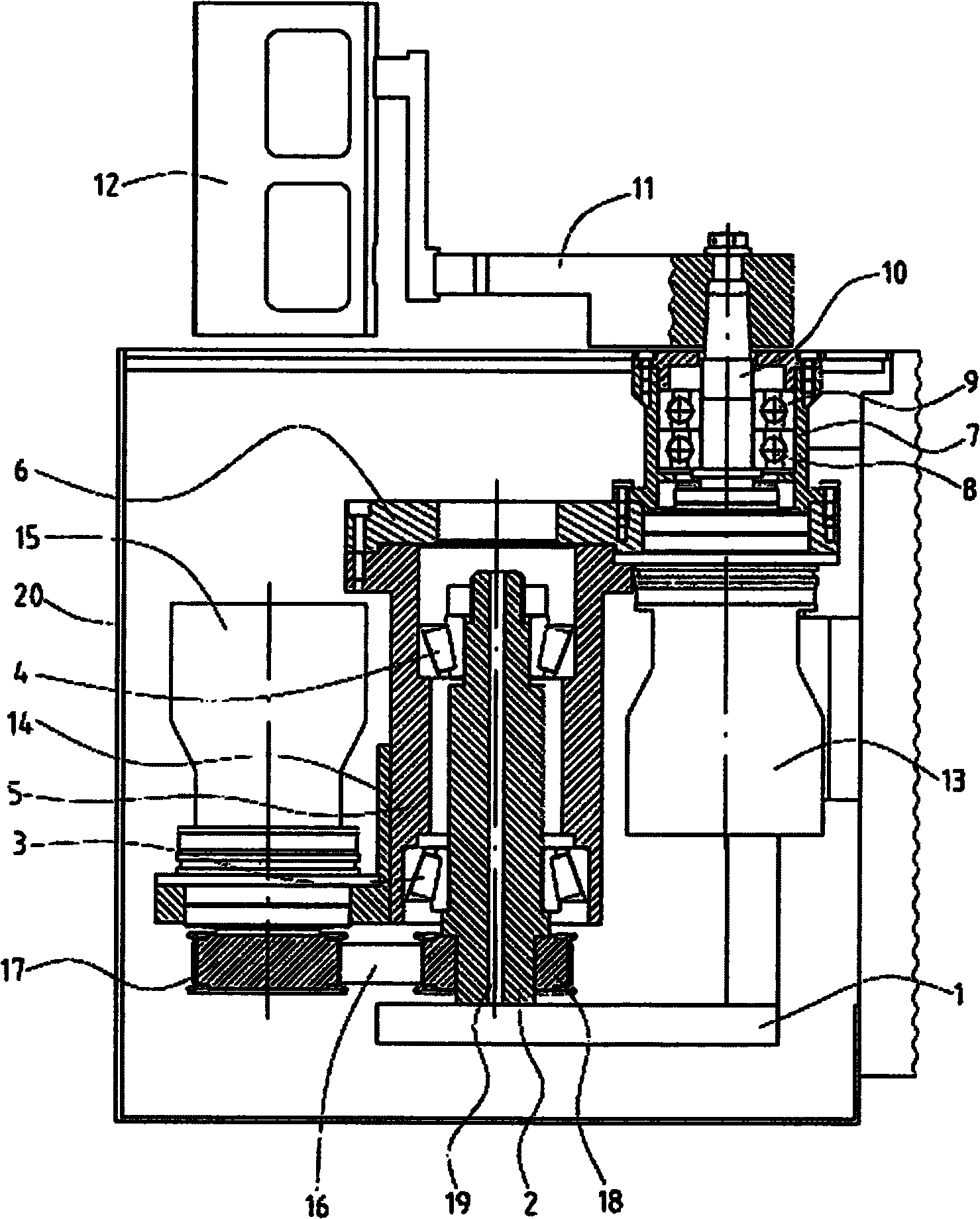

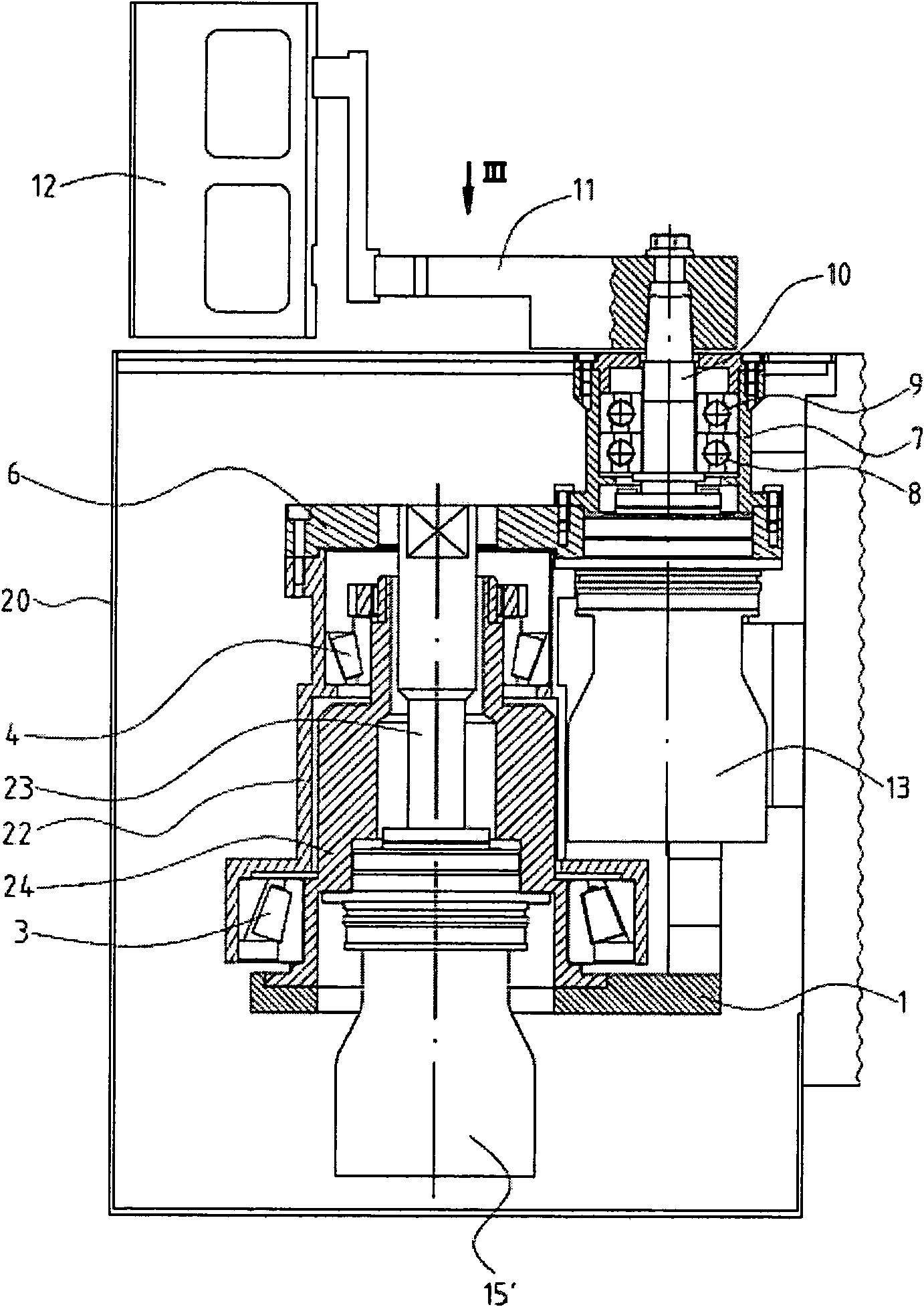

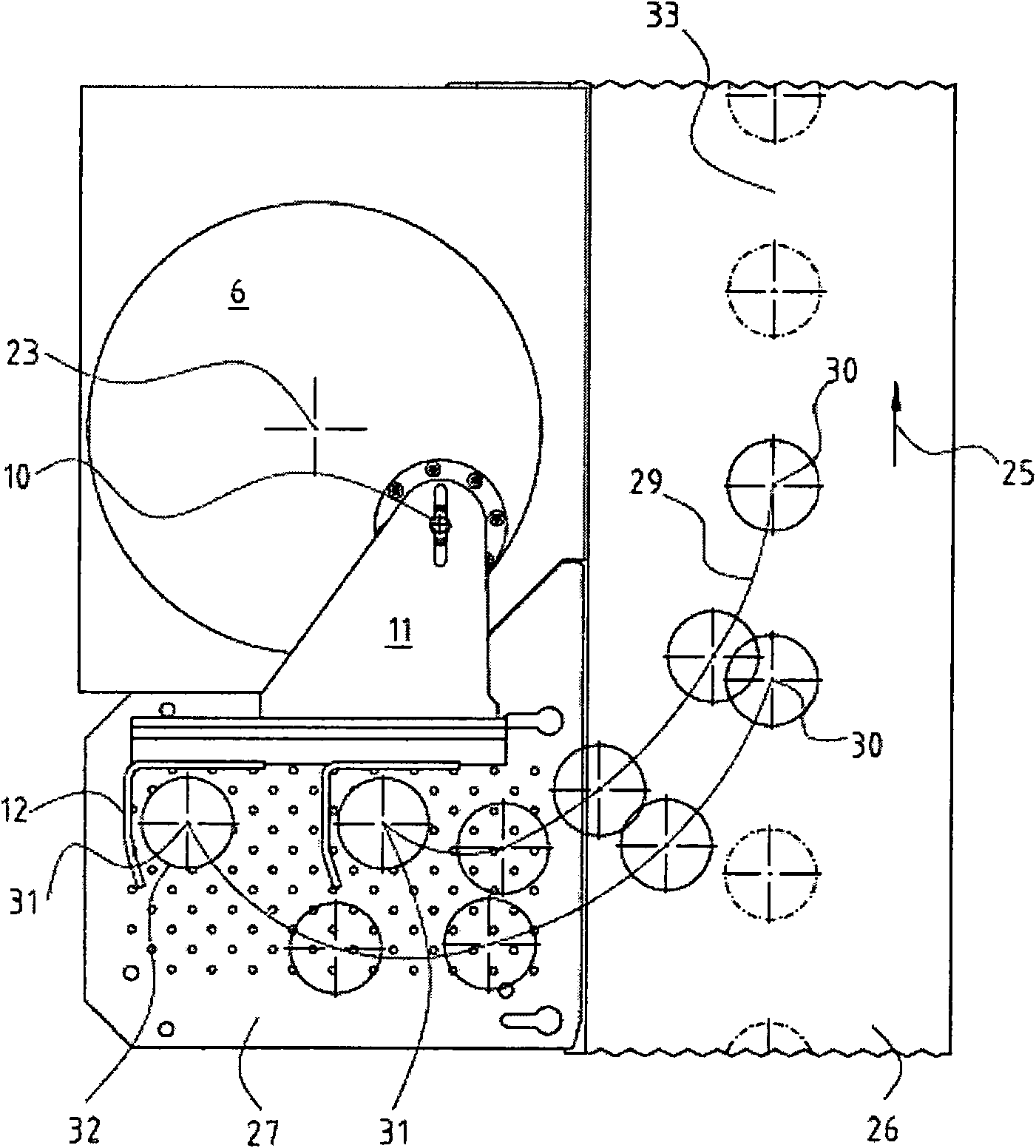

[0022] exist figure 1 1 denotes a horizontal support fixed on the not shown frame of the IS-machine, the hollow shaft 5 is supported on the support by means of rolling bearings 3, 4 around a fixedly arranged vertically extending shaft 2 formed hollow, the hollow The shaft 5 is fixedly connected at its upper end to the turntable 6 .

[0023] A bearing flange 7 is fixedly connected with the turntable 6, and a shaft 10 is supported inside the bearing flange through rolling bearings 8, 9. The upper end of the shaft 10 is fixedly connected with one end of a horizontally extending transfer device 11, and the other end of the transfer device is pressed The known way is equipped with an arrangement of push fingers 12 . The pushing fingers 12 of this arrangement are intended to bear directly against the hollow glass objects to be moved from the placement plate onto the conveyor belt.

[0024] 13 denotes an electric first rotary drive, such as a servo motor, which is fixedly arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com