PE pipe conveying device for repairing old sewage pipeline

A technology for sewage pipelines and conveying devices, which is applied to the field of PE pipe conveying devices for repairing old sewage pipelines, can solve the problems of inconvenient transportation of PE pipelines to the leakage point, etc., and achieves the effect of reliable driving process and improved stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The application will be described in further detail below in conjunction with the accompanying drawings.

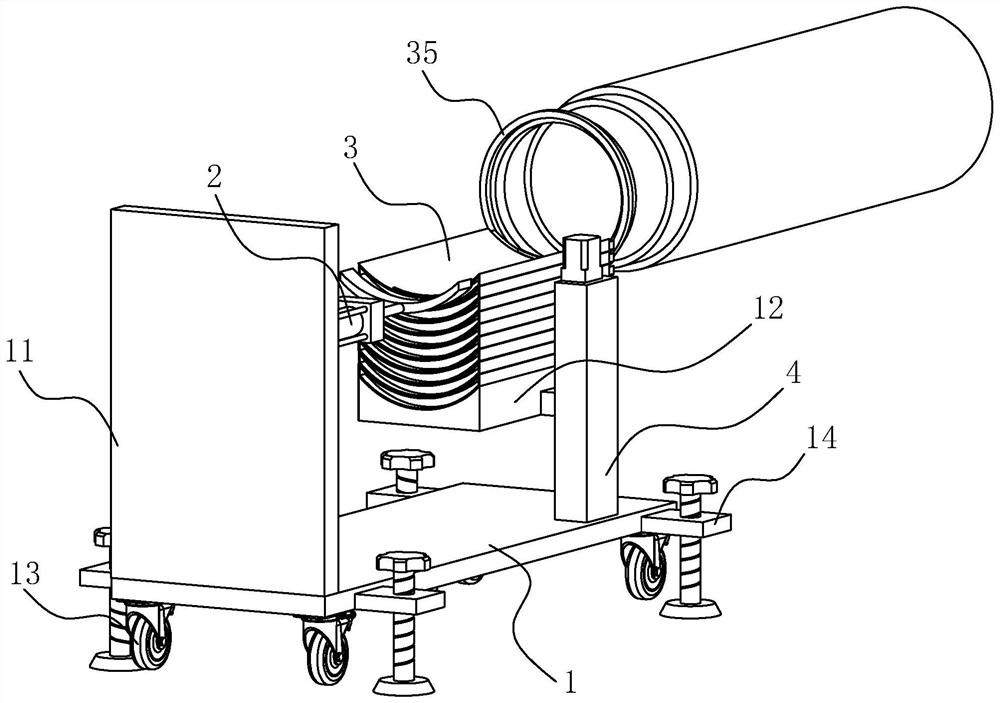

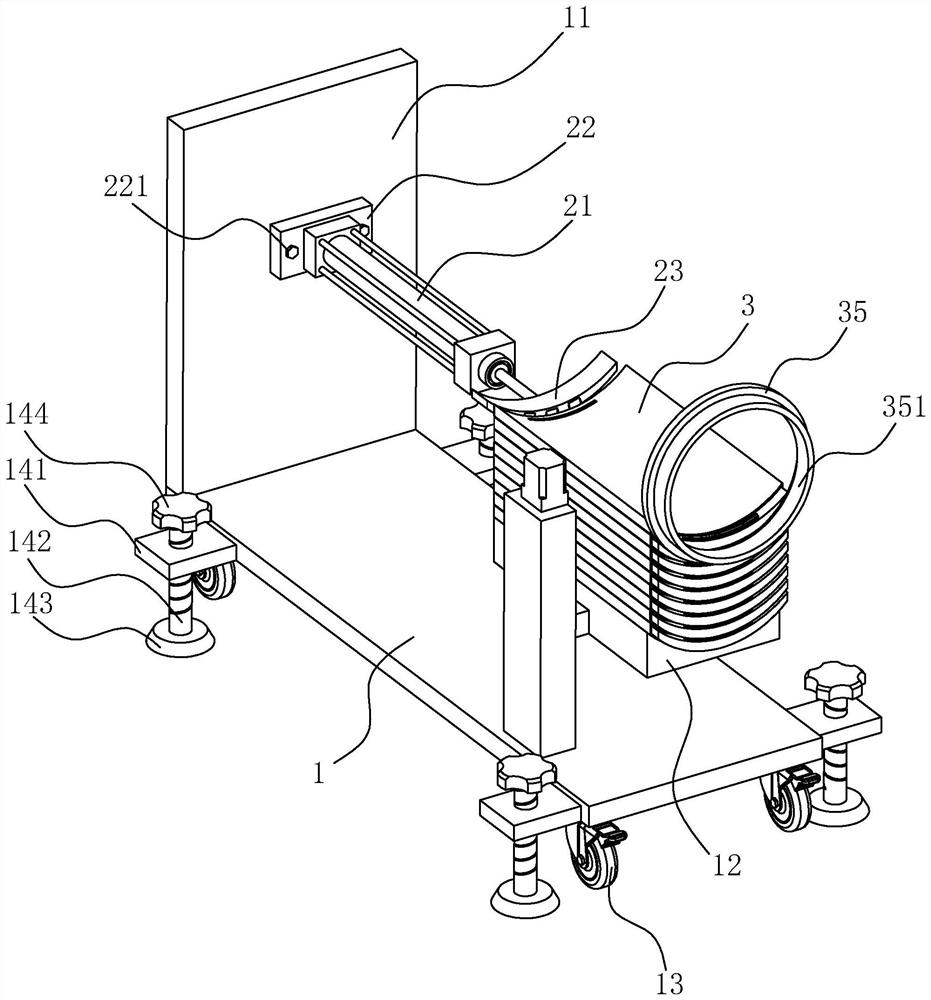

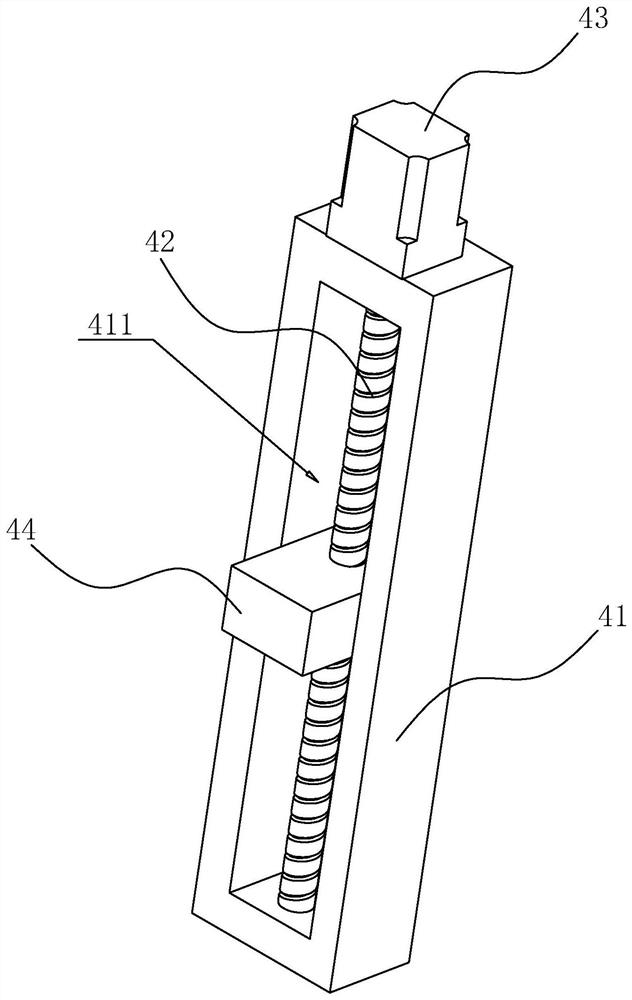

[0040] The embodiment of the present application discloses a PE pipe conveying device for repairing old sewage pipes, referring to figure 1 , figure 2 , including a base 1, one end of the base 1 is vertically welded with a support base 11, a horizontal drive mechanism 2 is installed on the support base 11, and the horizontal drive mechanism 2 includes a drive cylinder 21 and a connection welded on the cylinder end of the drive cylinder 21 The plate 22 can fix the driving cylinder 21 on the support seat 11 through the connecting plate 22 . On the base 1 and on one side of the horizontal drive mechanism 2 is provided with a vertical drive mechanism 4, a placement seat 12 is installed on the vertical drive mechanism 4, and a plurality of push plates 3 are stacked on the placement seat 12, and the horizontal drive mechanism 2 By driving the pushing piece 3 to move a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com