Electric Linear Direct Drive

A driving device, linear technology, applied in the direction of electromechanical devices, electric components, electrical components, etc., can solve the problems of difficulty in maintaining the preload, small life expectancy, too loose sliding seat, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

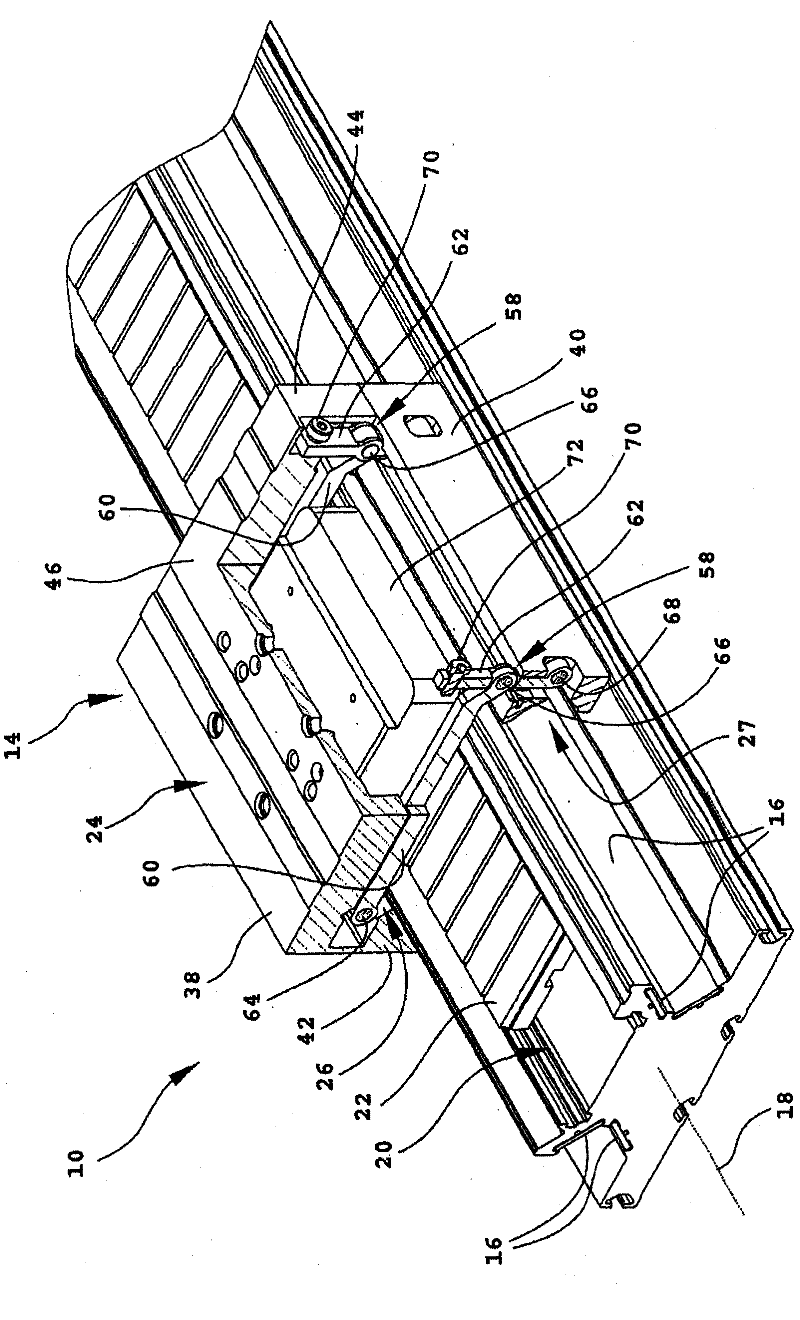

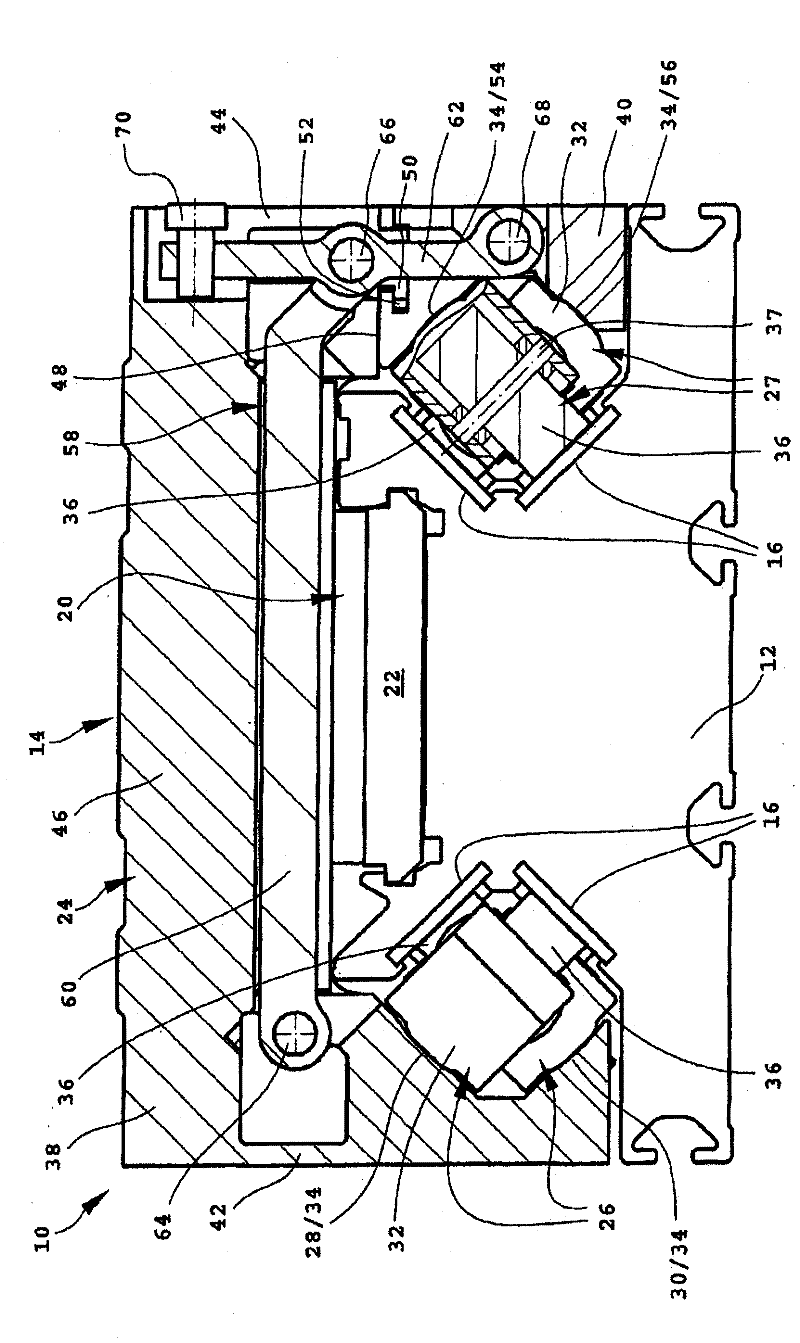

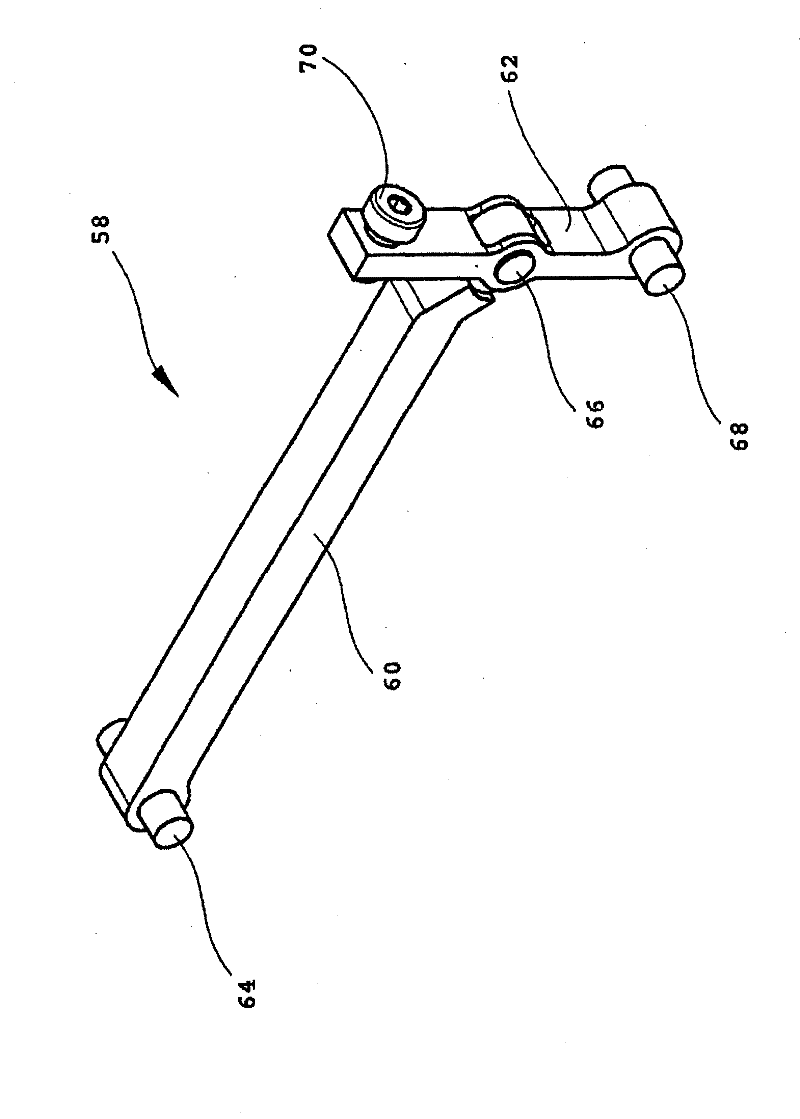

[0029] exist figure 1 The linear direct drive 10 shown in FIG. 2 comprises a rail-like straight (geradlinig) longitudinally extending base element 12 and a linearly movable carriage 14 arranged on the base element 12 .

[0030] The base element 12, which is preferably produced as an extruded part made of aluminum, has a plurality of preferably planar guide elements 16, for example configured as guide surfaces, which are expediently produced from strip-shaped steel sheets in order to ensure Low-wear force transmission between slide 14 and base element 12 . The guide device 16 is planarly They are supported on the base element 12 and are oriented in a V-shape relative to one another, for example in pairs, wherein, for example, they can enclose a right angle. The guide means are arranged on opposite sides of the base element 12 in such a way that an X-shaped arrangement of the guide means 16 results, whereby the guide means 16 form corresponding pairs of undercuts, the shape o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com