Device for separated assembling of dry-quenching hoister frame

A hoist and CDQ technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of unscheduled arrival, high entry cost, and impact on the construction period, so as to save the cost of mechanical shifts and facilitate construction , cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

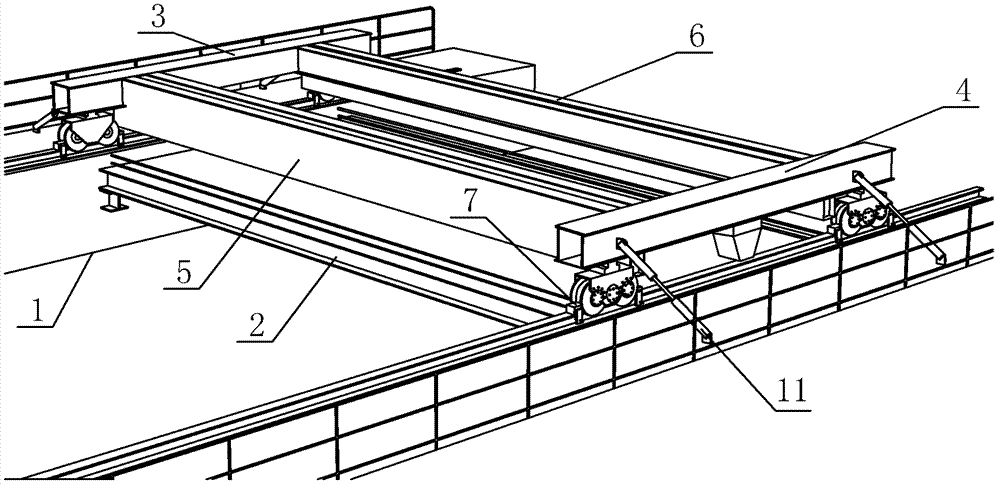

[0021] The device provided by the present invention for the installation of CDQ hoisting locomotive frames in pieces has a structure including an adjustable end beam fixing mechanism 11 and a wheel fixing mechanism 7 .

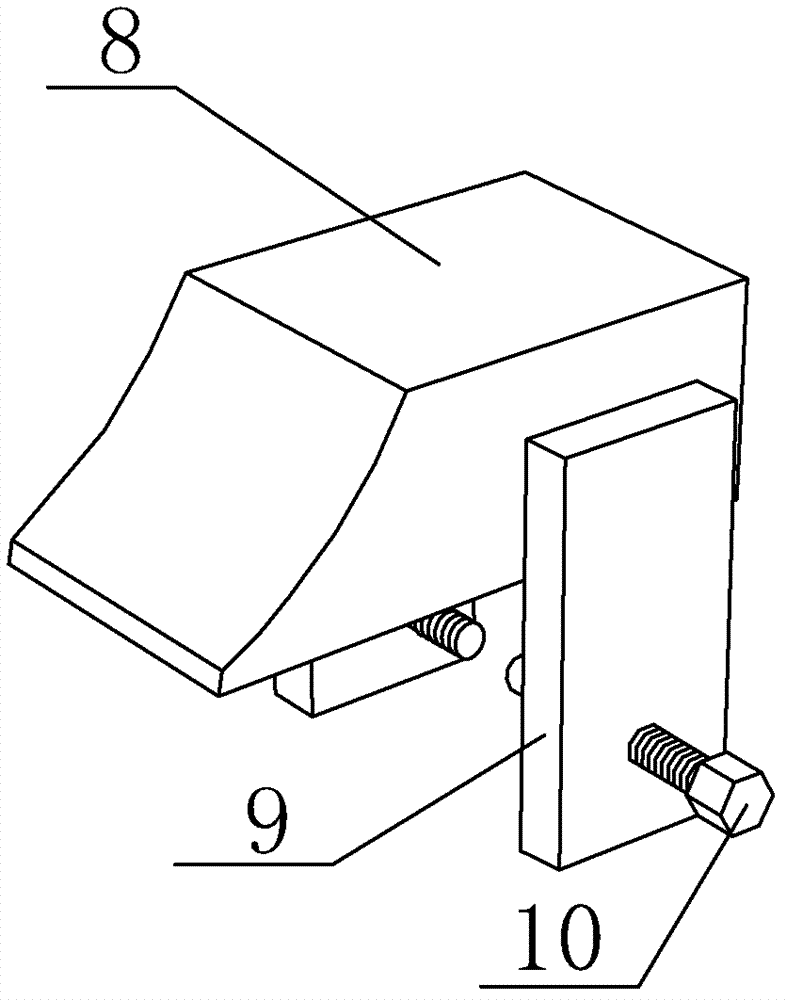

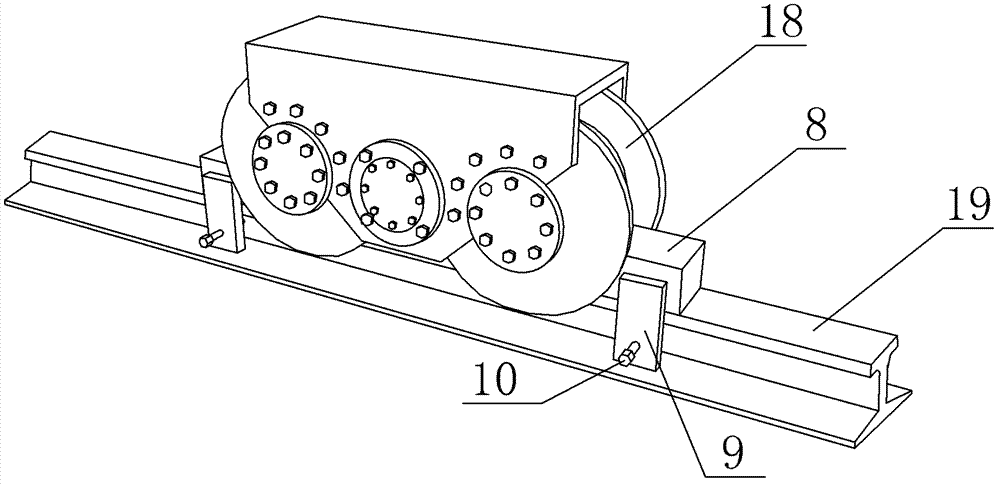

[0022] The wheel fixing device 7 provided by the present invention has a structure such as figure 1 and figure 2 As shown, it is mainly composed of spacer 8, spacer clamping plate 9 and jacking bolt 10, wherein: spacer 8 is welded by steel plate with a thickness of 10 mm, the cross section is square, and the width of spacer 8 is greater than or equal to that of track 19. Surface width; the end of the pad 8 in contact with the wheel 18 is processed into an arc surface so as to withstand the wheel 18 tightly. Pad block clamping plate 9 adopts the steel plate of thick 20mm to make, and this steel plate has two, welds with the both sides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com