A kind of preparation method of micro-dot anti-counterfeiting film

An anti-counterfeiting film, micro-dot technology, applied in the direction of copying/marking method, printing, etc., can solve problems such as discomfort and skin allergy, and achieve good anti-counterfeiting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

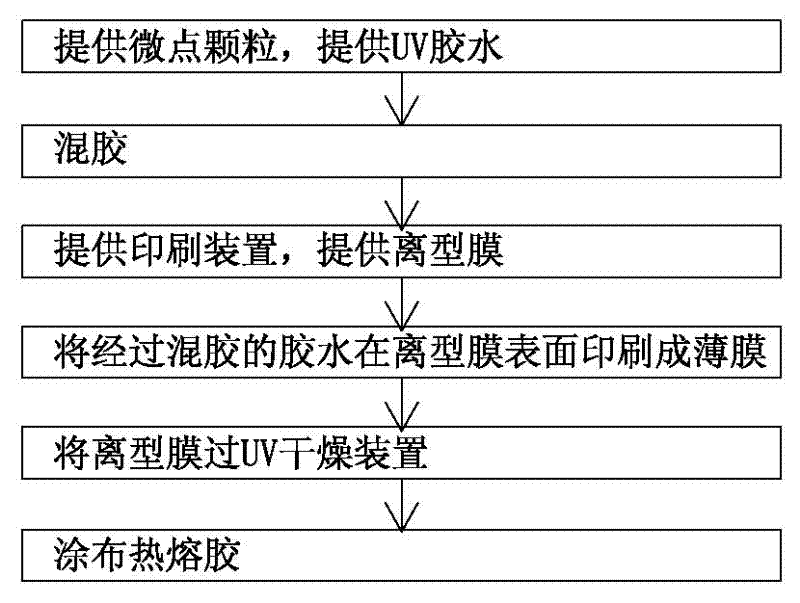

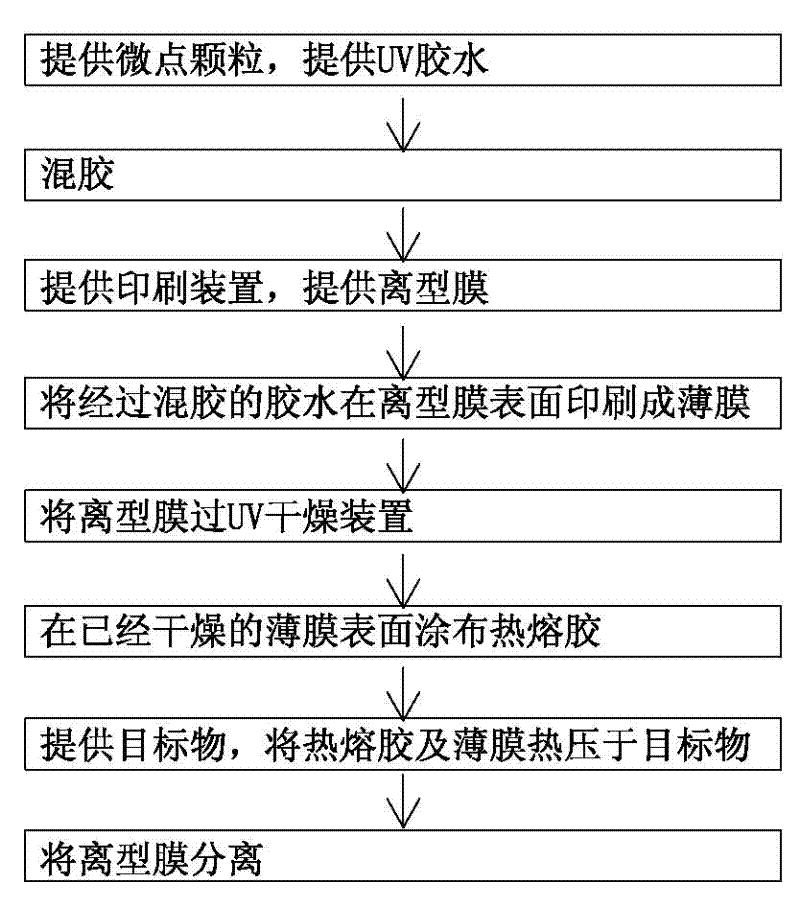

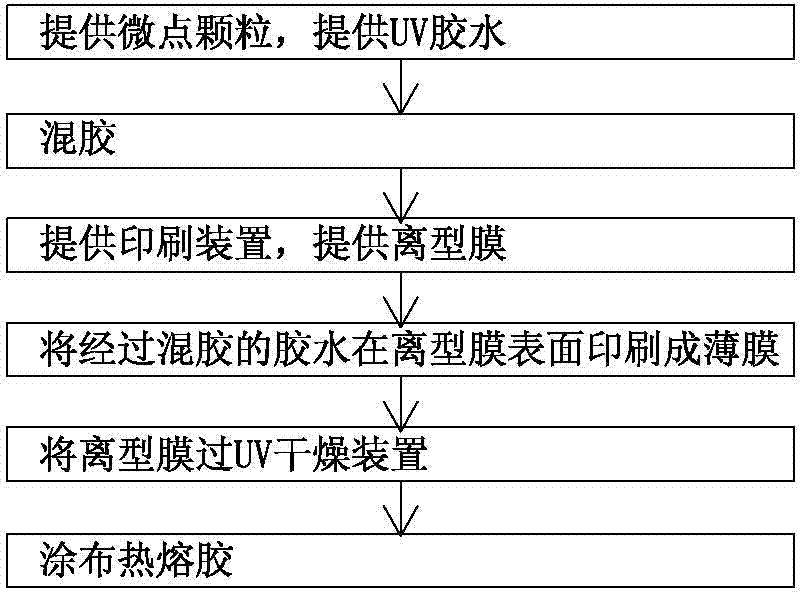

[0025] refer to figure 1 , the first embodiment of the present invention is a method for preparing a micro-dot anti-counterfeiting film, which is used to prepare a thermally transferable micro-dot anti-counterfeiting film, which is characterized in that it includes the following steps: S1, providing a micro-dot particle, providing UV glue ; S2, mixing glue, adding micro-dot particles to UV glue, and mixing evenly; S3, providing a printing device, providing a release film; S4, printing the glue mixed into a film on the surface of the release film; S5, Pass the release film through a UV drying device; S6, apply hot melt adhesive on the surface of the dried film.

[0026] As an improvement of this embodiment, the following step may be further included: S35, coating release oil, this step is arranged before the step S4. Furthermore, the micro-dot anti-counterfe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com