Spring-Pulley UAV Catapult

A technology of aircraft catapult and UAV, which is applied in the field of aerospace and UAV. It can solve the problems that the performance is greatly affected by temperature and humidity, cannot be effectively ejected, and the elastic force of the elastic band is limited. It achieves large traction and simple structure. , Adjust the effect of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

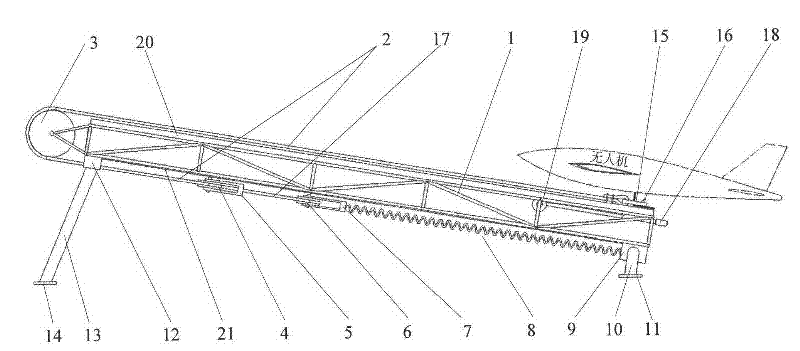

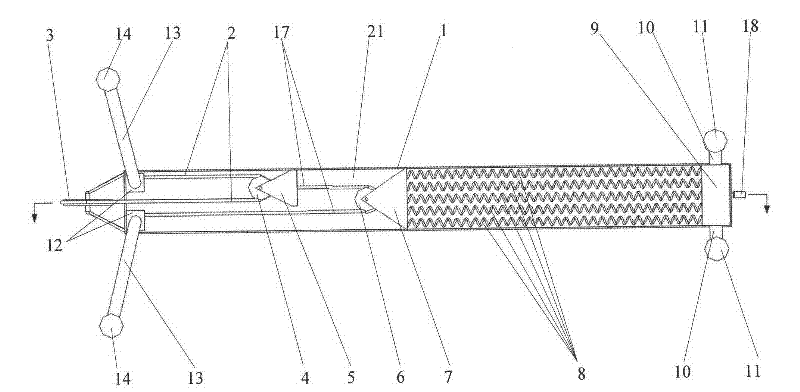

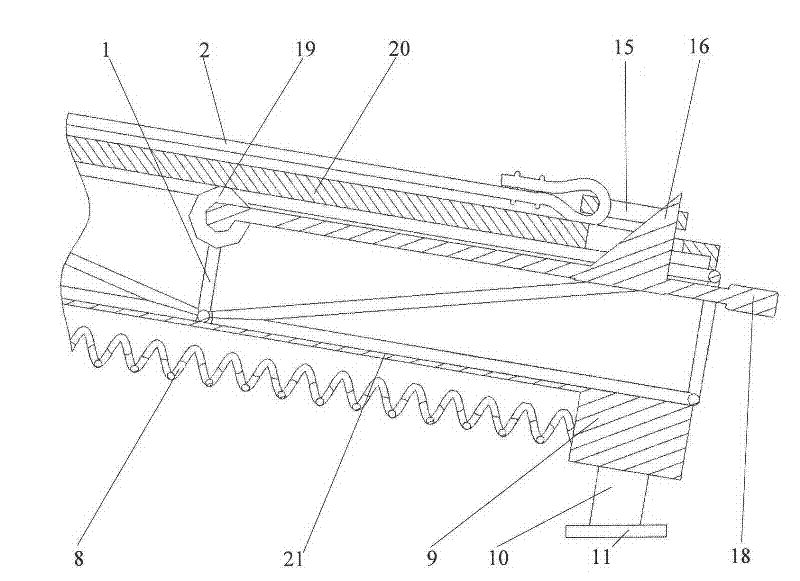

[0026] The spring-pulley group UAV catapult is mainly composed of the UAV catapult frame part, the UAV catapult support part, the spring-pulley group type ejection part, the UAV traction part and the UAV lock-release part.

[0027] The frame part of the UAV catapult includes: an upper panel 20, a lower panel 21, and a support rod assembly 1 between the upper and lower panels;

[0028] UAV catapult supporting part, containing: front load-bearing frame 12, the front support leg 13 that links to each other with this front load-bearing frame 12, the front support plate 14 that links to each other with this front support leg 13, and rear load-bearing frame 9, The back supporting leg 10 that links to each other with this rear bearing frame 9, the back supporting plate 11 that links to each other with this rear supporting leg 10; The described front bearing frame 12 links to each other with the bottom surface of lower panel 21, and described rear bearing frame 9 also Connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com