Production method of copper clad steel

A copper-clad steel and continuous casting technology, which is applied in the field of copper-clad steel and its production, can solve the problems of cracking, iron oxide scale pressing, rolling and slippage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

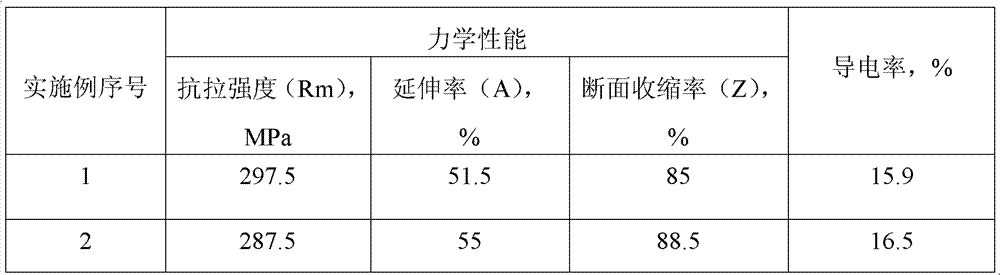

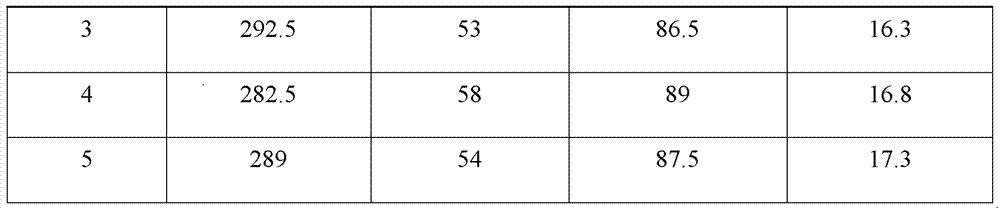

Examples

Embodiment 1

[0027] Steel for copper clad steel, its composition and weight percentage are: C: 0.01%, Si: 0.0083%, Mn: 0.12%, Als: 0.01%, P: 0.015%, S: 0.010%, the rest is iron and unavoidable of impurities.

[0028] The method for producing steel for copper clad steel, the steps:

[0029] 1) Smelting and continuous casting into billets;

[0030] 2) The components and weight percentages are C: 0.01%, Si: 0.0083%, Mn: 0.12%, Als: 0.01%, P: 0.015%, S: 0.010%, and the rest are iron and unavoidable impurities. Billet heating, the temperature of the heating section is controlled at 1120-1130 °C, and the temperature of the soaking section is controlled at 1080-1090 °C;

[0031] 3) Rough rolling is carried out on the high line, and the rolling start temperature is 1030-1040°C;

[0032] 4) Finish rolling is carried out on the high line, the controlled finish rolling inlet temperature is 895-900°C, and the controlled sizing temperature is 890-895°C;

Embodiment 2

[0038] Steel for copper clad steel, its composition and weight percentage are: C: 0.0097%, Si: 0.009%, Mn: 0.072%, Als: 0.008%, P: 0.011%, S: 0.008%, the rest is iron and unavoidable of impurities.

[0039] The method for producing steel for copper clad steel, the steps:

[0040] 1) Smelting and continuous casting into billets;

[0041] 2) The composition and weight percentage are: C: 0.0097%, Si: 0.009%, Mn: 0.072%, Als: 0.008%, P: 0.011%, S: 0.008%, and the rest are iron and unavoidable impurities. Slab heating, the temperature of the heating section is controlled at 1140-1150°C, and the temperature of the soaking section is controlled at 1095-1105°C;

[0042] 3) Rough rolling is carried out on the high line, and the rolling start temperature is 1045-1055 °C;

[0043] 4) Finish rolling is carried out on the high line, the controlled finish rolling inlet temperature is 905-910°C, and the controlled sizing temperature is 900-905°C;

Embodiment 3

[0049] Steel for copper clad steel, its composition and weight percentage are: C: 0.0086%, Si: 0.0081%, Mn: 0.096%, Als: 0.013%, P: 0.009%, S: 0.008%, the rest is iron and unavoidable of impurities.

[0050] The method for producing steel for copper clad steel, the steps:

[0051] 1) Smelting and continuous casting into billets;

[0052] 2) The composition and weight percentage are: C: 0.0086%, Si: 0.0081%, Mn: 0.096%, Als: 0.013%, P: 0.009%, S: 0.008%, and the rest are iron and unavoidable impurities. The billet is heated, the temperature of the heating section is controlled at 1190-1200°C, and the temperature of the soaking section is controlled at 1120-1130°C;

[0053] 3) Rough rolling is carried out on the high line, and the rolling start temperature is 1080-1090°C;

[0054]4) Finish rolling is carried out on the high line, the controlled finish rolling entrance temperature is 915-920°C, and the controlled sizing temperature is 905-910°C;

[0055] 5) Spinning, the spin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com