One-piece horizontal movable type garbage compressor

A garbage compressor and horizontal movement technology, which is applied in the direction of garbage transmission, garbage collection, loading/unloading, etc., can solve the problems of high investment cost, low efficiency of garbage collection and transportation, and low compaction density of compressed garbage, so as to achieve garbage compression High density, light weight, compact and solid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

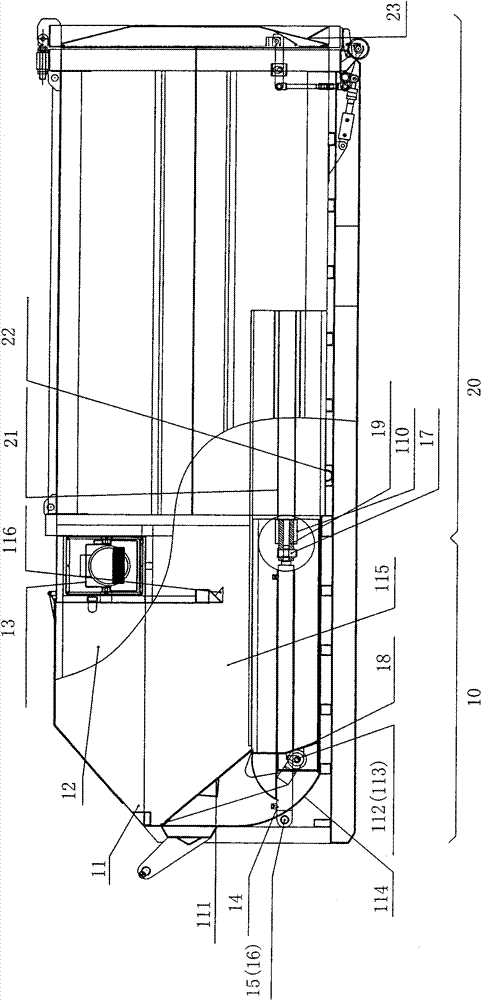

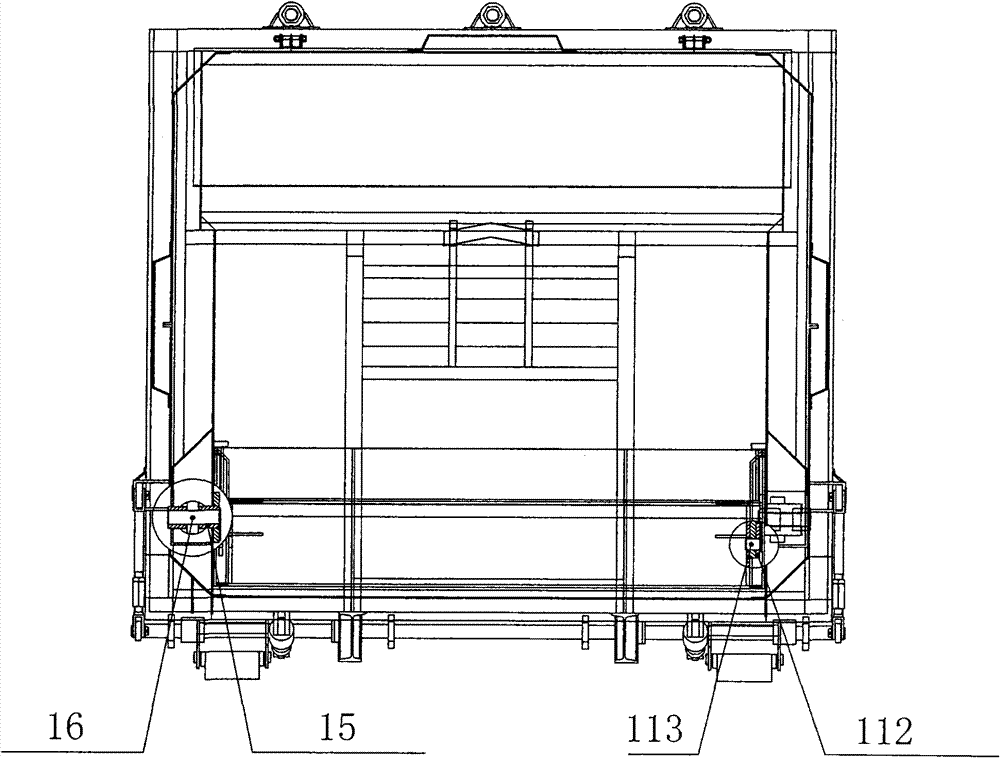

[0040] Such as Figure 1-21 As shown, a conjoined horizontal mobile garbage compressor includes a compressor 10 and a garbage container 20, the garbage container 20 is connected to the compressor 10 and the bottom of the garbage container 20 communicates with the compressor 10, and the compressor 10 includes There is a compressor bracket 11, the upper part of the compressor bracket 11 is provided with a feeding port 12, and a hydraulic station 13 is also provided in the compressor bracket 11, and two hydraulic oil cylinders 14 connected with the hydraulic station 13 are also provided at the lower part of the compressor bracket 11 , the two hydraulic cylinders 14 are horizontally and symmetrically arranged on both sides of the compressor support 11, and the fixed ends of the hydraulic cylinders 14 are connected with the corresponding support cylinder seats 16 fixed on the compressor support 11 through the corresponding cylinder pins 15. The piston rod ends 141 of the branch hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com