Improved variable compression ratio piston for internal combustion engine

An improved, compression ratio technology, used in pistons, mechanical equipment, engine components, etc., can solve the problems of rapid piston reset, rapid changes in stiffness, short service life, etc., to overcome the slow response speed of load changes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

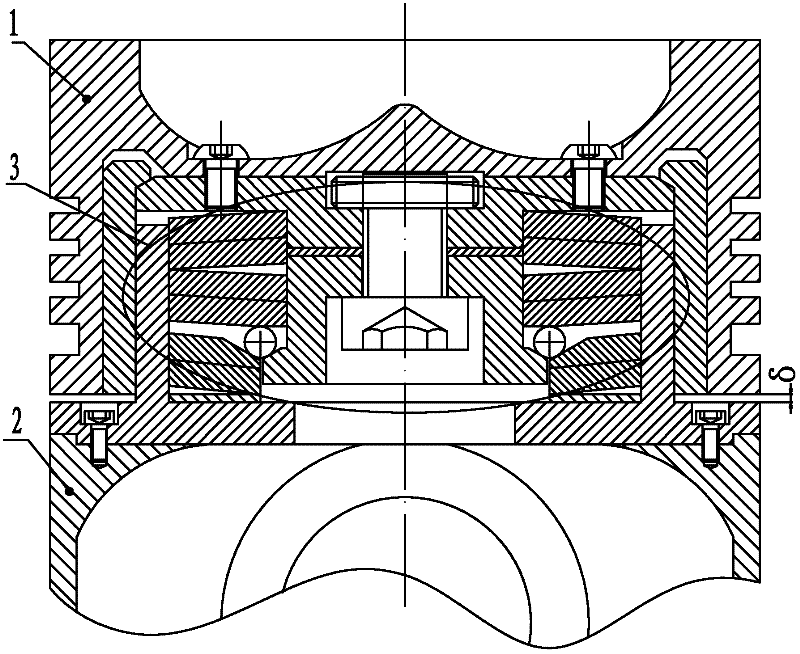

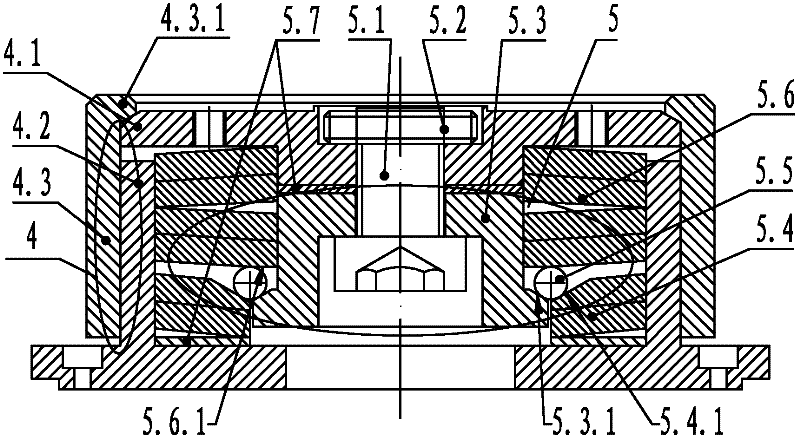

[0028] The improved variable compression ratio piston of the internal combustion engine shown in the figure includes a piston crown 1 and a piston skirt 2, and a compression ratio adjusting device 3 is arranged between the piston crown 1 and the piston skirt 2. The compression ratio adjusting device 3 includes an adjusting device housing 4 and a mechanical elastic deformation mechanism 5 .

[0029] The regulating device housing 4 is composed of a circular pressure plate 4.1 fixedly connected to the bottom surface of the piston top 1 by a locking screw, an inner cylinder located below the circular pressure plate 4.1 and fixedly connected to the top surface of the piston skirt 2 by a locking screw 4.2, and an outer cylinder 4.3 that is threadedly connected with the inner cylinder 4.2. An inner stop ring 4.3.1 is provided at the mouth o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal inclination | aaaaa | aaaaa |

| Horizontal inclination | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com