A high-efficiency oil-free scroll compressor for both gas and liquid media

A scroll compressor, liquid medium technology, applied in the direction of rotary piston machinery, liquid fuel engine, mechanical equipment, etc., can solve the problem of reducing the working efficiency of scroll compressor 4", achieve low maintenance cost and improve working efficiency , the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

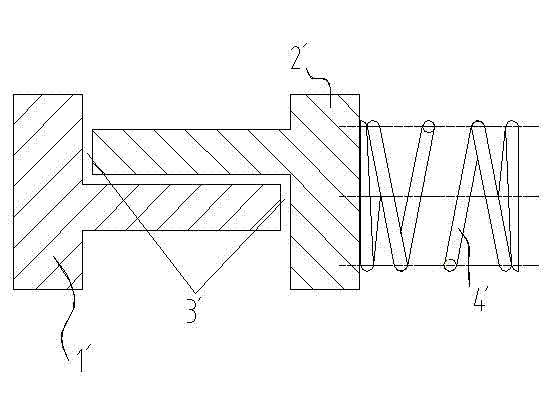

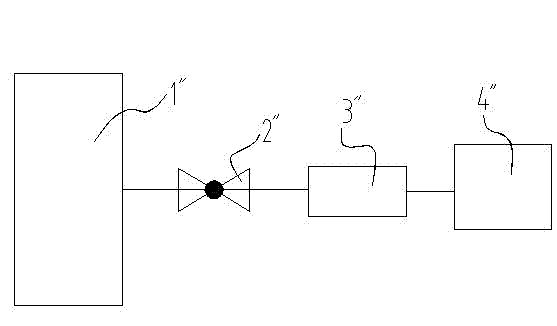

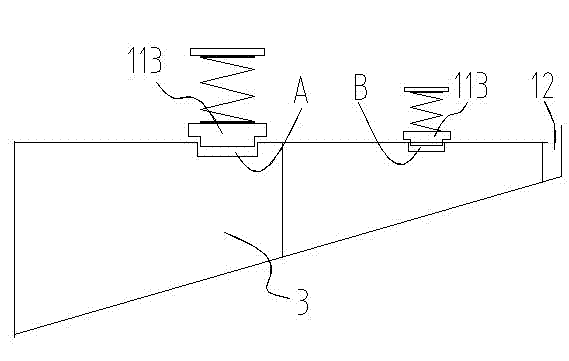

[0022] Such as Figure 3-6 As shown, a high-efficiency oil-free scroll compressor for both gas and liquid media includes a scroll stationary disk 1 and a scroll moving disk 2 . Wherein, the vortex static disk 1 is provided with disk teeth 11 to form an alveolar structure, and a main outlet 12 is arranged at the center of the alveolar structure. The teeth 21 of the scroll movable disk perform circular translation in the tooth grooves of the scroll static disk, and the inner tooth surface of the scroll movable disk tooth 21 is close to the outer tooth surface of the scroll static disk tooth 11 for sliding displacement.

[0023] There are several bypass outlets 112 communicating with the main outlet 12 at intervals in the alveolar structure formed by the stationary scroll teeth 11. In this embodiment, there are two bypass outlets, which are bypass outlet A and bypass outlet A respectively. exit B. Each bypass outlet A, B is provided with a pressure balance regulating valve 113...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com