Arrangement structure of transmission gear shaft system

A technology for arranging structures and gear shafts, applied in the directions of gear transmissions, belts/chains/gears, transmissions, etc., can solve the problems of difficult matching of number ratios, long axial distance, unreasonable arrangement of gear shafts, etc. Reasonable, short axial distance and balanced arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

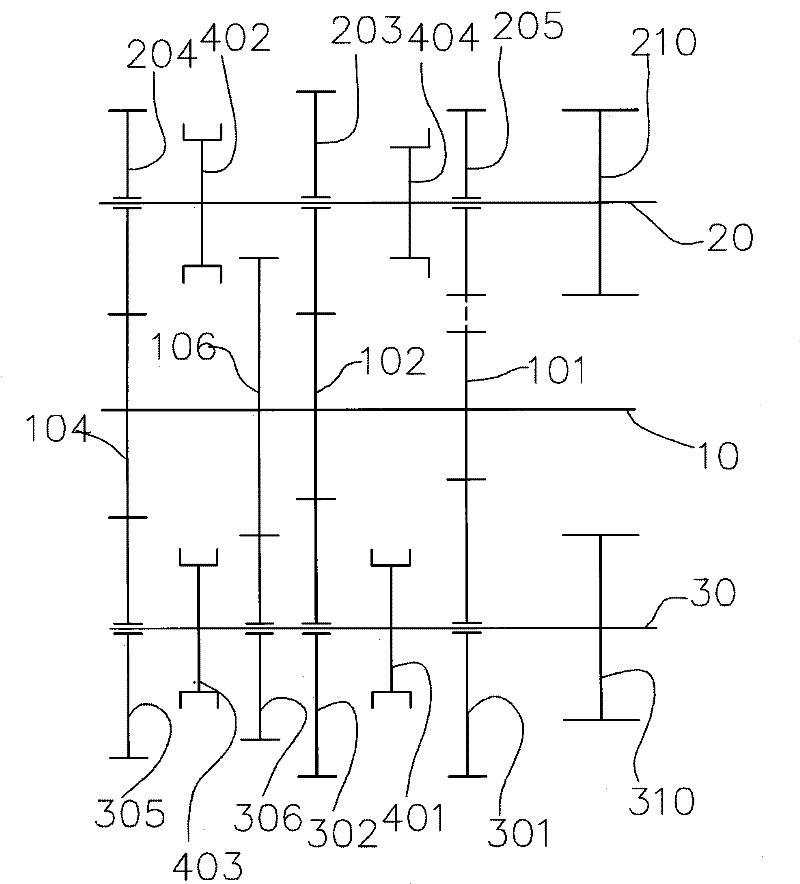

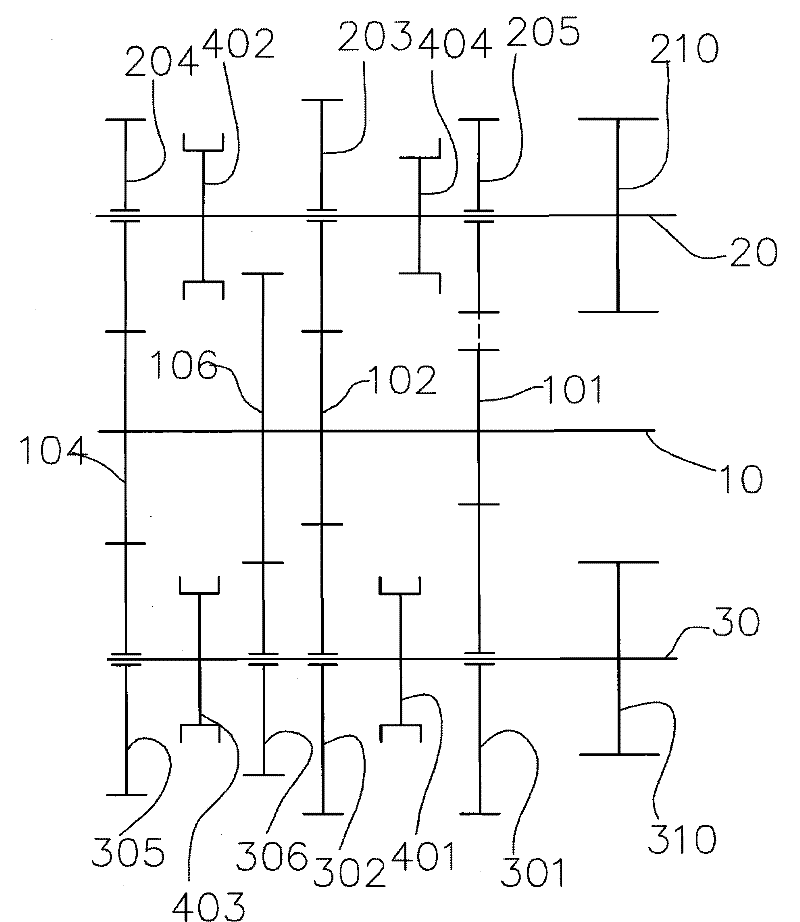

[0021] like figure 1 As shown, in the best embodiment of the layout structure of the manual gearbox gear shaft system of the present invention, an input shaft 10 is arranged in the manual gearbox, and the first output shaft 20 and the The second output shaft 30, the input shaft 10 is fixedly provided with a driving gear 101 for first gear, driving gear 102 for second and third gears, driving gear 104 for fourth and fifth gears and driving gear 106 for sixth gear, wherein, the driving gear 106 for sixth gear is arranged on between the second and third gears 102 and the fourth and fifth gears 104 .

[0022] A reverse gear 205 , a third gear driven gear 203 , and a fourth gear driven gear 204 are sheathed on the first output shaft 20 . The third gear driven gear 203 meshes with one end of the second and third gears 102, and can be driven to rotate by the second and third gears 102; the fourth gear driven gear 204 meshes with one end of the fourth and fifth gears 104, And can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com