A manufacturing method for conveniently installing led track lights

A manufacturing method and a technology that is easy to install, applied in the field of electronic optics, can solve the problems affecting the promotion and application of LED lighting, time-consuming and labor-intensive costs, harsh conditions, etc., to reduce installation, replacement and maintenance costs, prolong service life, and facilitate The effect of installation, maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, the present invention is described in further detail with preferred embodiment:

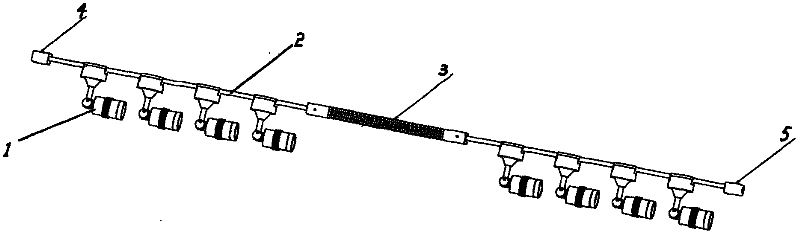

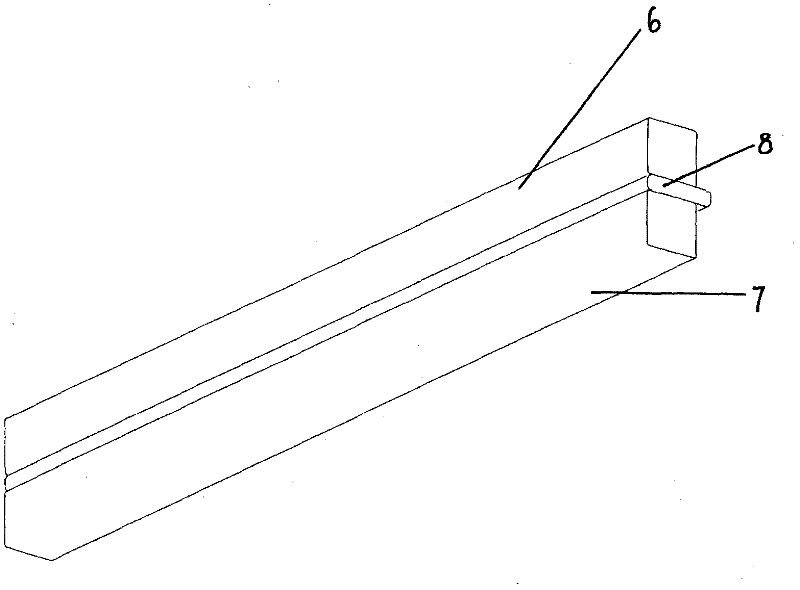

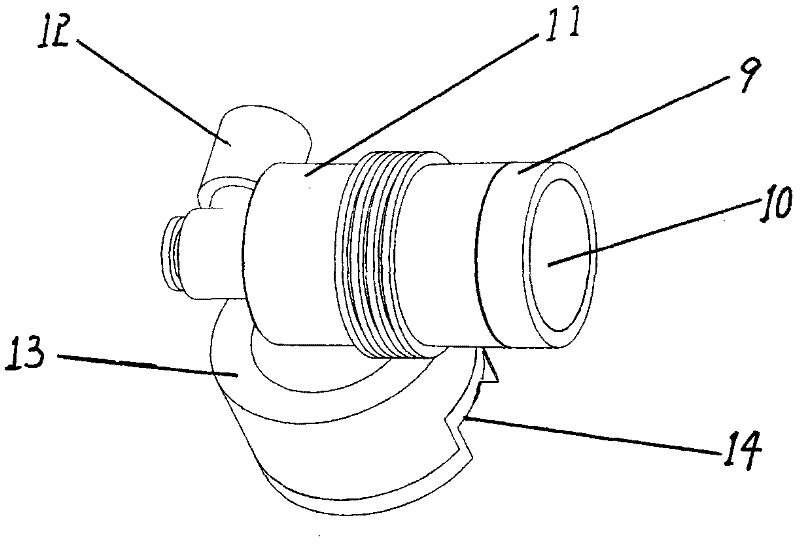

[0016] The invention consists of LED lighting lamps (1) and guide rails (2). 4 LED lighting lamps (1) are clamped on the guide rail (2); the LED lighting lamp (1) is composed of a lamp cap part, a radiator connector (12) and a base part, and the lamp cap part is successively composed of a face cover (9), a lens ( 10), LED lamp bead (15), aluminum substrate (16) and cooling body (11); the base part consists of double-headed dental tube (18), base (13), base plastic part (19), magnet A ( 20) and magnet B (21); the radiator connector (12) is provided with limit screws (17), which are respectively connected to the lamp head part and the base part; the lamp head part can rotate 350° along the radiator connector (12) , the lamp head part and the radiator connector (12) can rotate 350° along the double-headed dental tube (18), which can meet the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com