Coil winding device

A winding device and wire technology, which is applied to electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of large-scale, complex and large-scale main center body 211, and achieve easy and simplified assembly and adjustment. Construct, reduce the number of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

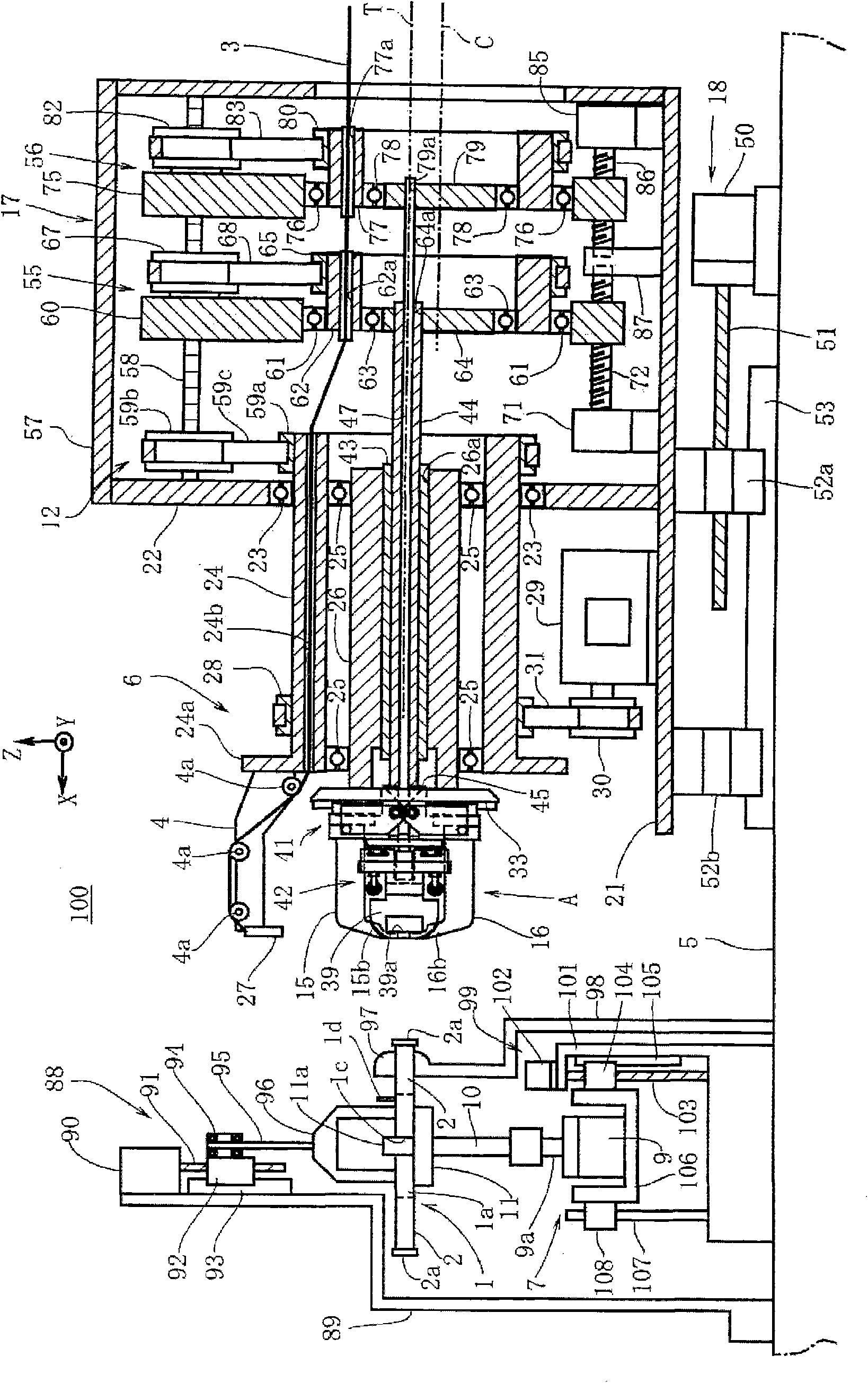

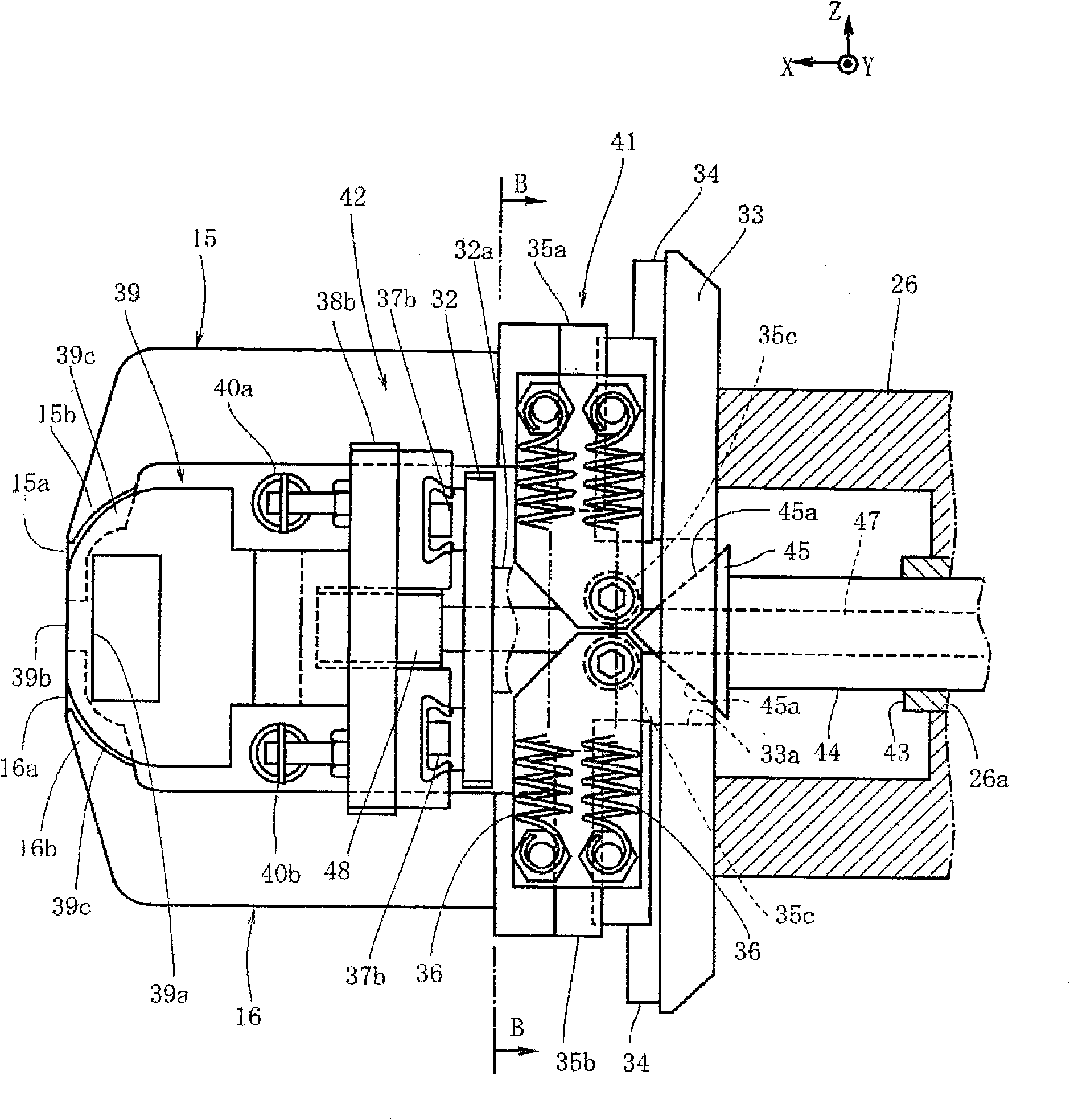

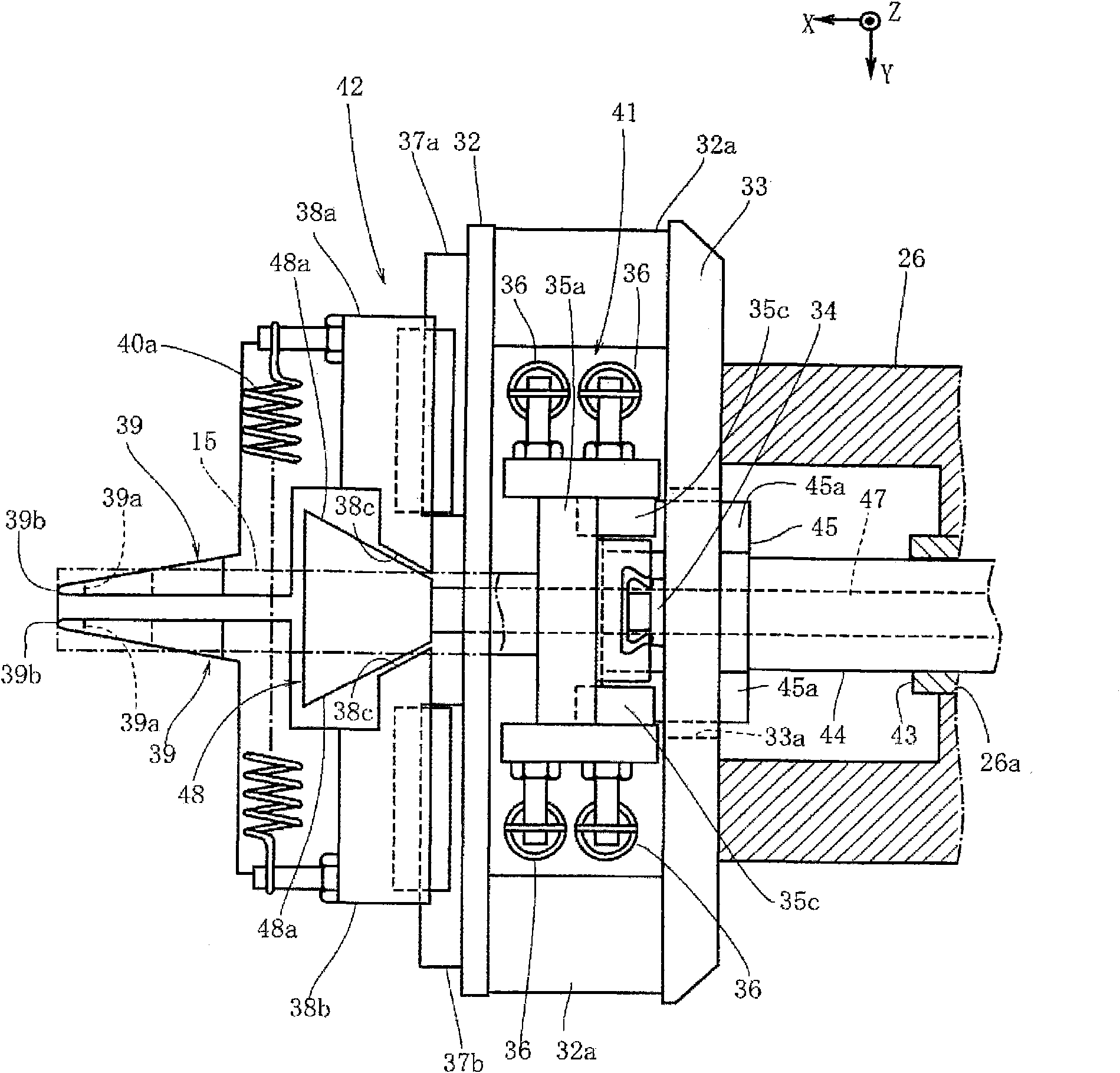

[0038] Next, the best mode for carrying out the present invention will be described with reference to the drawings.

[0039] figure 1 Shown is the winding device 100 of the present invention. This winding device 100 is a device that uses a plurality of magnetic poles 2 constituting a multi-pole armature 1 of a generator or motor as a winding core, and winds a multilayer wire 3 around the magnetic poles 2 as the winding core. That is, it is a flyer-type winding device 100 that performs winding using the flyer 4 that rotates around the magnetic pole 2 while drawing out the wire 3 . The multi-pole armature 1 in the present embodiment is formed to include an annular portion 1 a and 18 magnetic poles 2 protruding radially outward from the annular portion 1 a ( Figure 6 Indicates 7 poles). like Figure 6 As shown, slots 1 b are formed between the magnetic poles 2 in the multi-pole armature 1 . The cross-section of the magnetic pole 2 as a winding core is quadrangular, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com