Device for simulating operation state of handcart switch cabinet

A handcart-type switch and operating state technology, applied in switchgear, pull-out switch cabinet, electrical components, etc., can solve the problem that personal and equipment safety cannot be guaranteed, affecting the efficiency of emergency repairs, cabinet rails, and valve switches. Contact deformation and other problems, to facilitate chassis troubleshooting, avoid repeated power outages, and shorten the maintenance time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

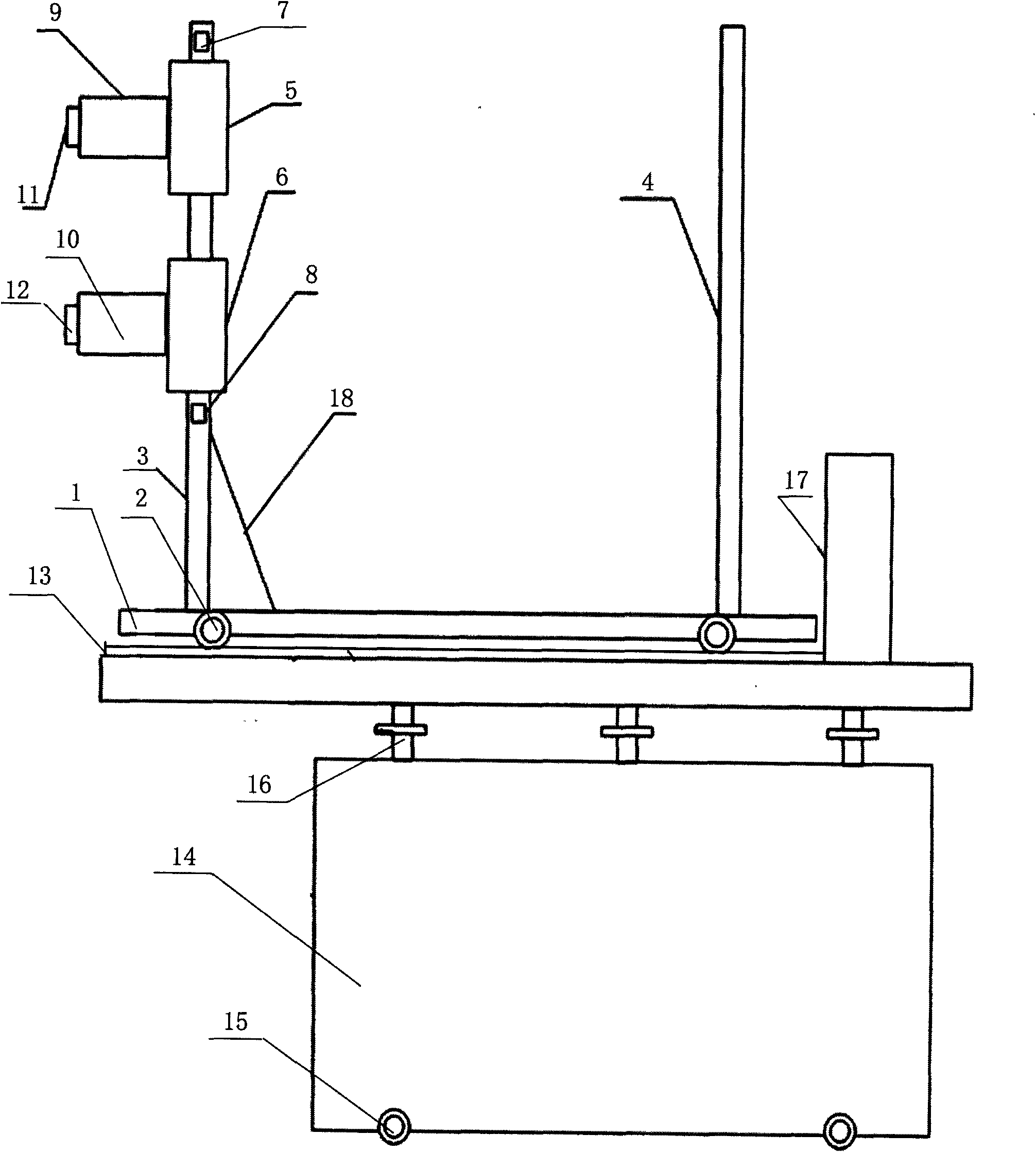

[0008] exist figure 1 Among them, the present invention provides a device for simulating the operating state of a handcart switchgear, which includes a handcart switch simulation device and a handcart switch platform. The handcart switch simulation device includes a bottom plate 1, and the two sides of the bottom plate There are pulleys 2, on both sides of the upper surface of the bottom plate 1 are respectively provided with a column 3 and a transparent plate 4, on the column 3 from top to bottom are respectively set with an upper horizontal plate 5 and a lower horizontal plate 6, the upper horizontal plate 5 and the lower horizontal plate The plate 6 slides up and down along the column 3, and an upper limit device 7 and a lower limit device 8 are respectively fixed on the upper part of the upper horizontal plate 5 and the bottom of the lower horizontal plate 6. The upper limit device 7 is set as an upper limit nail stop and a lower limit The device 8 is set as a lower limit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com