Static iron core and its assembly method

An assembly method and technology of static iron core, applied in the direction of sounding equipment, instruments, sensors, etc., can solve the problems of large tolerance range, small deformation size of riveted rear face, change of air gap, etc., to achieve stability and consistency guarantee, stability The effect of good stability and consistency, and increased air gap accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with specific embodiments and the accompanying drawings shown therein. In the following embodiments of the present invention, the static iron core of the electric car horn is taken as an example for illustration, but the present invention is not limited to these embodiments.

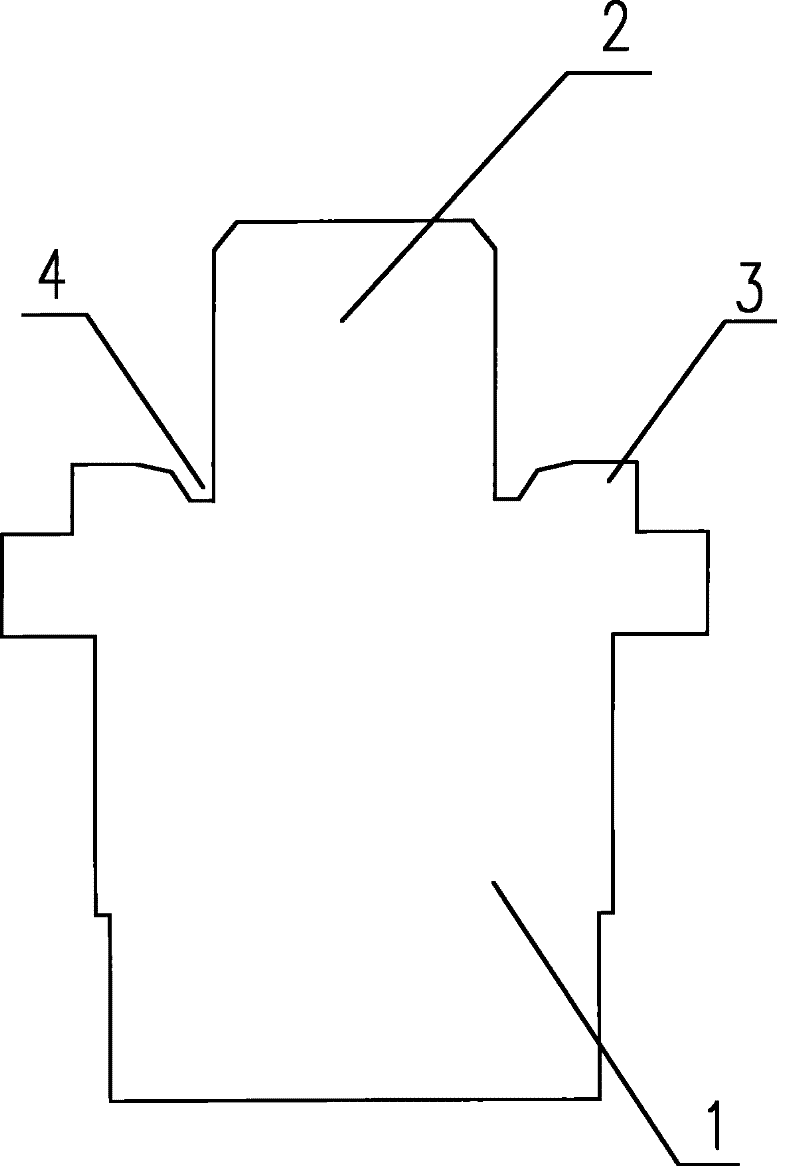

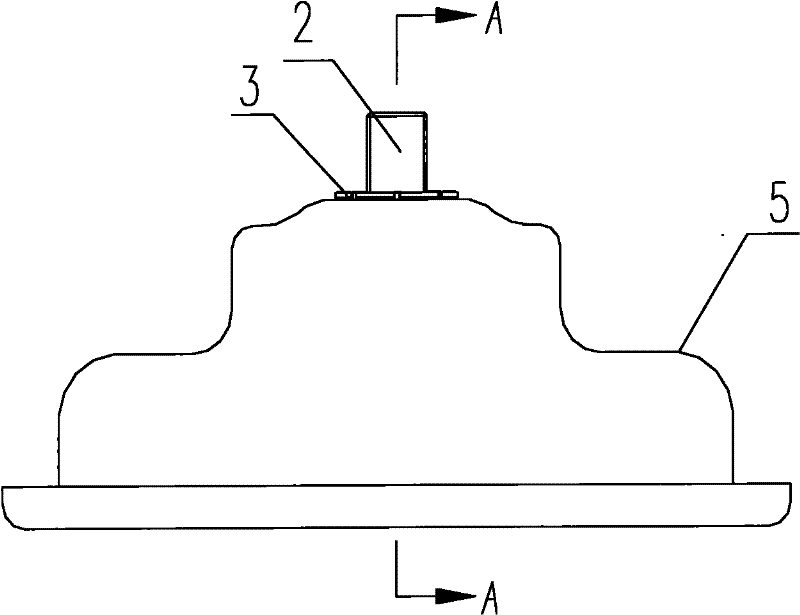

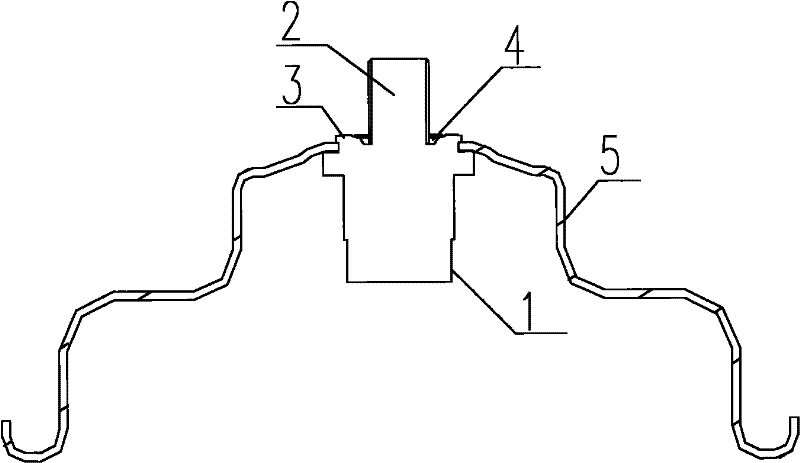

[0017] refer to figure 1 , which is a schematic longitudinal section of the static iron core of the present invention. The static iron core is a static iron core for an automobile electric horn, and it includes an iron core body 1 and a stud 2, and the stud 2 is positioned at one end of the iron core body 1, from which figure 1 It can be clearly seen that the stud 2 is formed at the central position of one end face of the iron core body 1, and there is a riveting part 3 on the outer edge of the stud 2, and the static iron core and the speaker base (not shown) are connected through the riveting part 3 achieve fixation....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com