A LED internal control guardrail tube control system

A technology of control system and guardrail tube, which is applied in the field of LED internal control guardrail tube control system, can solve the problems of inflexible practical application, inconvenient maintenance, and easy confusion of on-site installation, so as to broaden the application range, improve system reliability, and reduce engineering costs. The effect of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

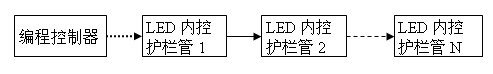

[0031] Such as figure 1 As shown, an internal control LED guardrail tube control system includes a programming controller and N LED internal control guardrail tubes. The N LED internal control guardrail tubes are connected in series according to the data flow direction, and the demonstration control content of the LED internal control guardrail tubes needs to be set. At the same time, the programming controller is connected to the first LED internal control guardrail tube; after the demonstration control content is updated, each LED internal control guardrail tube can work independently. At this time, the programming controller can be disconnected from the first LED internal control guardrail tube . The function of the programming controller is to generate the demonstration control data of each LED internal control guardrail tube and transmit it to the first LED internal control guardrail tube, and then transmit it to the second LED internal control guardrail tube connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com