Method for improving flotation recovery rate

A technology of flotation recovery rate and process method, which is applied in the field of improving flotation recovery rate, and can solve problems such as large grinding energy consumption, over-grinding of target minerals, and influence on process, so as to improve flotation recovery rate and flotation recovery rate Improve and reduce the effect of grinding fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

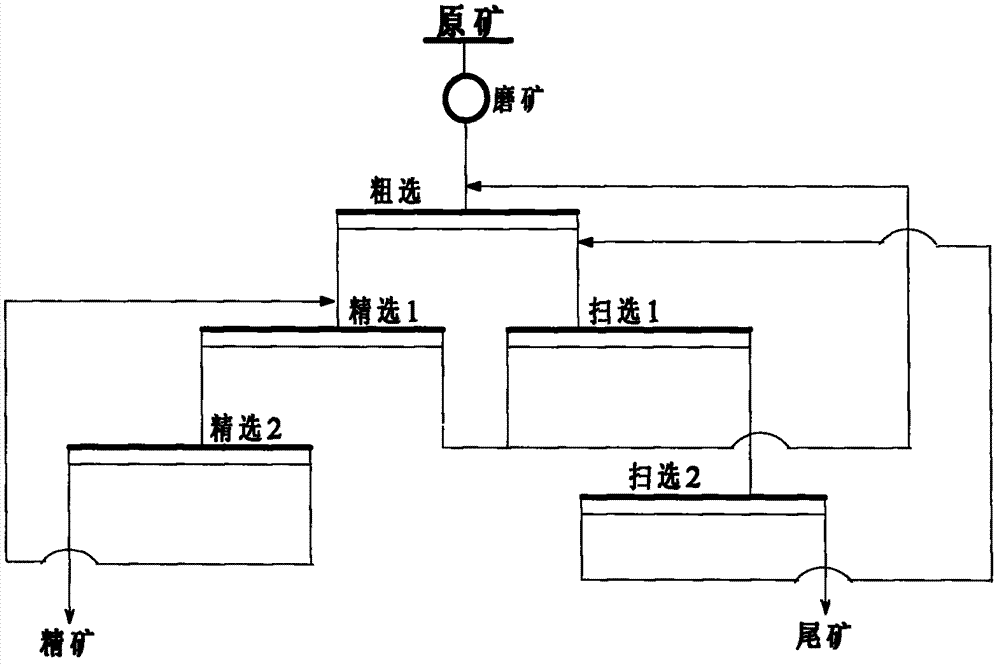

Embodiment 1

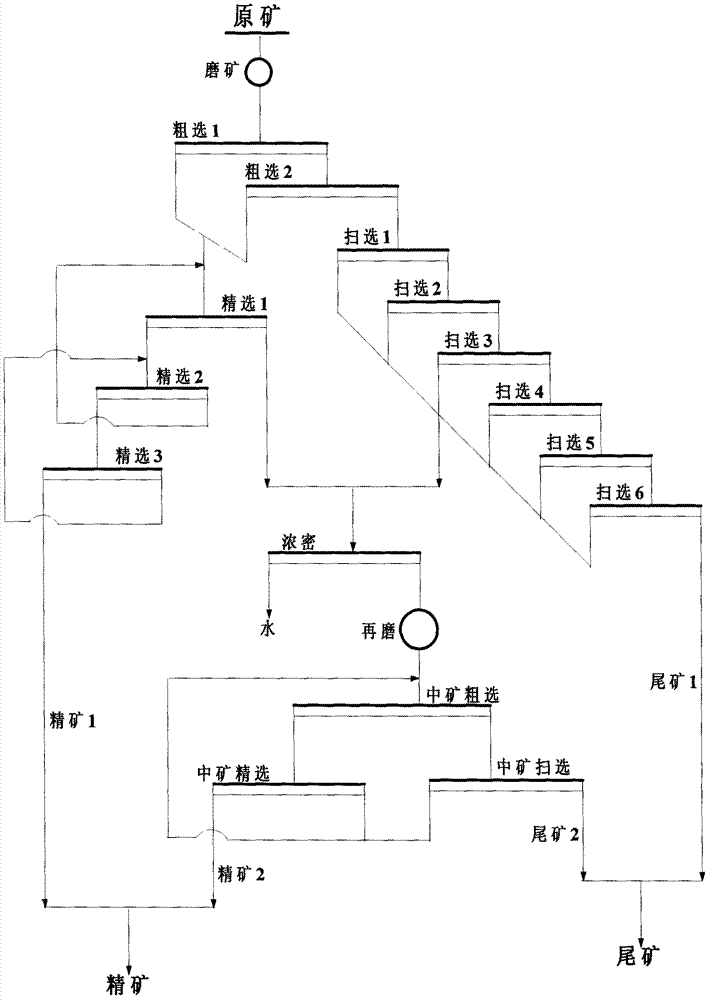

[0053] Applying the process method of the present invention, after grinding the same raw ore as that of Comparative Example 1 to -0.074mm and accounting for 60%, the copper concentrate 1 and the tailings 1 are produced through one roughing, two beneficiation, and four sweeping, Then combine the tank bottom product of the selection 1 and the foam product of the four times of sweeping to form a medium ore and thicken it to a weight concentration of 30%, then grind it to -0.035mm and account for 60%, and then pass the reground pulp through a coarse Sorting, one-time beneficiation, and one-time sweeping return to the technological process to obtain copper concentrate 2 and tailings 2, and finally combine copper concentrate 1 and copper concentrate 2 to obtain the final copper concentrate. The copper grade of the final copper concentrate is 18.92%, and the copper recovery rate is 89.23%.

[0054] Comparing Example 1 and Comparative Example 1, it is found that under the same raw mat...

Embodiment 2

[0058] Applying the process method of the present invention, after grinding the raw ore identical to that of Comparative Example 2 to -0.074mm and accounting for 50%, gold concentrate 1 and tailings 1 were produced through two roughings, three beneficiations, and eight sweepings. Then combine the tank bottom product of the selection 1 and the foam product of the eight times of sweeping to form a medium ore and thicken it to a weight concentration of 25%, then grind it to -0.038mm and account for 50%, and then pass the reground pulp through a coarse Sorting, double-sweeping, and twice-sweeping are returned to the technological process to obtain gold concentrate 2 and tailings 2, and finally gold concentrate 1 and gold concentrate 2 are combined to obtain the final gold concentrate. The gold grade of the final gold concentrate is 62.69g / t, and the gold recovery rate is 90.27%.

[0059] Comparing Example 2 and Comparative Example 2, it was found that under the same raw materials,...

Embodiment 3

[0063] Applying the process method of the present invention, after grinding the raw ore identical to that of Comparative Example 3 to -0.074mm and accounting for 65%, the lead concentrate 1 and tailings 1 are produced through one roughing, two beneficiation, and three sweeping, and then The tank bottom product of the selection 1 and the foam product of the third sweeping are combined to form a medium ore, which is thickened to a weight concentration of 45%, and then ground to -0.038mm to account for 80%, and then the reground pulp is passed through a roughing, One beneficiation and one scavenging return to the technological process in sequence to obtain lead concentrate 2 and tailings 2, and finally lead concentrate 1 and lead concentrate 2 are combined to obtain the final lead concentrate. The lead grade of the final lead concentrate is 58.84%, and the lead recovery rate is 95.35%.

[0064] Comparing Example 3 and Comparative Example 3, it is found that under the same raw mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com