Efficient magnetization roasting process for magnetic pulse pretreatment of refractory iron ore

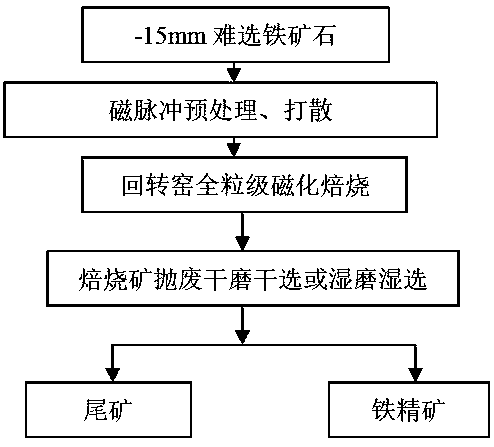

A technology of magnetization roasting and iron ore, applied in the field of mineral processing, can solve the problems of high grinding cost, long magnetization roasting time and high temperature of refractory iron ore, achieve high-efficiency magnetization roasting, shorten magnetization roasting time, and reduce magnetization The effect of firing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Adopt a kind of refractory iron ore magnetic pulse pretreatment high-efficiency magnetization roasting process of the present invention, the -15mm Jing Tieshan refractory iron ore of grade 32% is subjected to the following treatment: specifically comprise the following steps:

[0021] Step A. Use magnetic pulse pretreatment-15mm Jingtieshan refractory iron ore, and break up;

[0022] Step B. Using a rotary kiln to directly carry out full-size magnetized roasting of -15mm refractory iron ore, roasting time is 50 minutes, roasting temperature is 740°C, reducing agent coal powder ratio is 1.5%, and the roasted ore is cooled to 35°C;

[0023] Step C. Carry out dry pre-selection, discarding, dry grinding and dry separation treatment on the roasted ore, and obtain the indicators of iron concentrate grade of 58% and metal recovery rate of 85%.

[0024] Compared with the indicators of magnetized roasting and dry grinding and dry separation of untreated mirrorite, the magnetized...

Embodiment 2

[0026] Using the high-efficiency magnetization roasting process for refractory iron ore magnetic pulse pretreatment of the present invention, the -15mm Jingtieshan refractory iron ore with a grade of 33% is subjected to the following treatment, which specifically includes the following steps:

[0027] Step A. Pretreat the -15mm Jingtieshan refractory iron ore by magnetic pulse pretreatment and break it up;

[0028] Step B. Using a rotary kiln to directly roast the -15mm refractory iron ore with full-grain magnetization, the roasting time is 55min, the roasting temperature is 710°C, the reducing agent coal powder ratio is 1.5%, and the roasted ore is cooled to 45°C;

[0029] Step C. Carry out dry pre-selection, discarding, wet grinding and wet separation treatment on the roasted ore, and obtain the indicators of iron concentrate grade of 60% and metal recovery rate of 90%.

[0030] Compared with the indicators of magnetization roasting and wet grinding and wet separation of unt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com