A method of producing magnesium titanate and direct-reduced iron by coal-based reduction and magnetic separation of titanomagnetite

A technology of titanium magnetite and magnesium titanate, applied in chemical instruments and methods, titanium compounds, inorganic chemistry, etc., can solve the problems of low yield, complex reaction process, harsh conditions, etc., and achieve the effect of comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

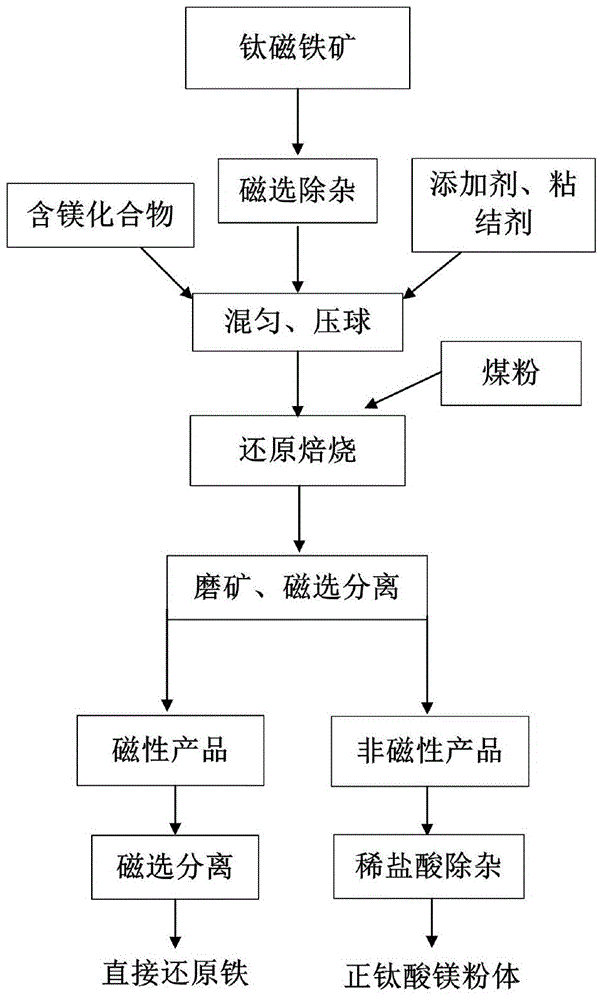

Method used

Image

Examples

Embodiment 1

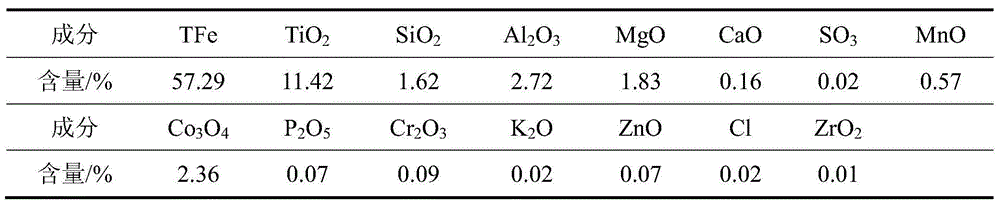

[0029] See Table 1 for the multi-element analysis of the magnetically separated concentrate (hereinafter referred to as the sample) obtained from a seaside titanomagnetite separated by a drum magnetic separator. Among them, the iron-containing minerals are mainly titano-magnetite, basically no gangue minerals, the contents of S and P are low, and V is not included. The particle size of the reducing agent coal used in the sample is -2mm, and the coal quality analysis is shown in Table 2

[0030] Table 1 Sample (seaside titanium magnetite magnetic separation concentrate) multi-element analysis

[0031]

[0032] Table 2 Analysis results of bituminous coal quality

[0033]

[0034] The distribution ratio of the main components is: 20g of the sample (magnetic separation concentrate) (-74μm accounts for 86.5%); the amount of the main raw material MgO is 25% of the sample mass; the amount of the binder CMC is 0.2% of the sample mass; In addition, an additive with a mass fract...

Embodiment 2

[0037] Table 3 shows the multi-element analysis of samples obtained from a titanium magnetite in Indonesia after wet weak magnetic separation. Among them, the iron-bearing minerals are mainly titanium magnetite, and the gangue minerals are very small, containing a small amount of V. The reducing agent for the reduction and roasting of the sample is anthracite with a particle size of -2mm, and the coal quality analysis is shown in Table 4

[0038] Table 3 Sample (a titanium magnetite concentrate in Indonesia) multi-element analysis

[0039]

[0040] Table 4 Analysis results of anthracite coal quality

[0041]

[0042]

[0043] In the direct reduction process, the sample size is 20g (-74μm accounts for 85.0%); the other main raw material is magnesite with MgO grade of 44.56%, and the dosage is 26% of the sample mass; the binder is CMC, and the dosage It is 0.25% of the mass of the sample; in addition, an additive with a mass fraction of 2.4% of the sample is added, th...

Embodiment 3

[0046] The iron-bearing minerals in a titanomagnetite in Yunnan are mainly titanomagnetite, with a small amount of ilmenite and biotite. The raw ore was subjected to wet weak magnetic separation after crushing and grinding, and the multi-element analysis of the obtained magnetic separation concentrate (hereinafter referred to as the sample) is shown in Table 5. The reducing agent used in the sample is bituminous coal, the particle size is -2mm, and the coal quality analysis is shown in Table 6

[0047] Table 5 Sample (seashore titanium magnetite magnetic separation concentrate) multi-element analysis

[0048]

[0049] Table 6 Analysis results of bituminous coal quality

[0050]

[0051] The distribution ratio of the main components is: 20g of the sample (magnetic separation concentrate) (-74μm accounts for 85.7%); the amount of the main raw material MgO is 22% of the sample mass; the amount of the binder CMC is 0.25% of the sample mass; In addition, an additive with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com