Processing method of tubular products by chipless cutting and cutting device thereof

A technology of shearing device and processing method, applied in shearing device, pipe shearing device, metal processing equipment and other directions, can solve the problems of poor working environment of workers, waste of metal materials, loss of metal materials, etc., to save metal pipes, reduce Production cost and effect of reducing carbon emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

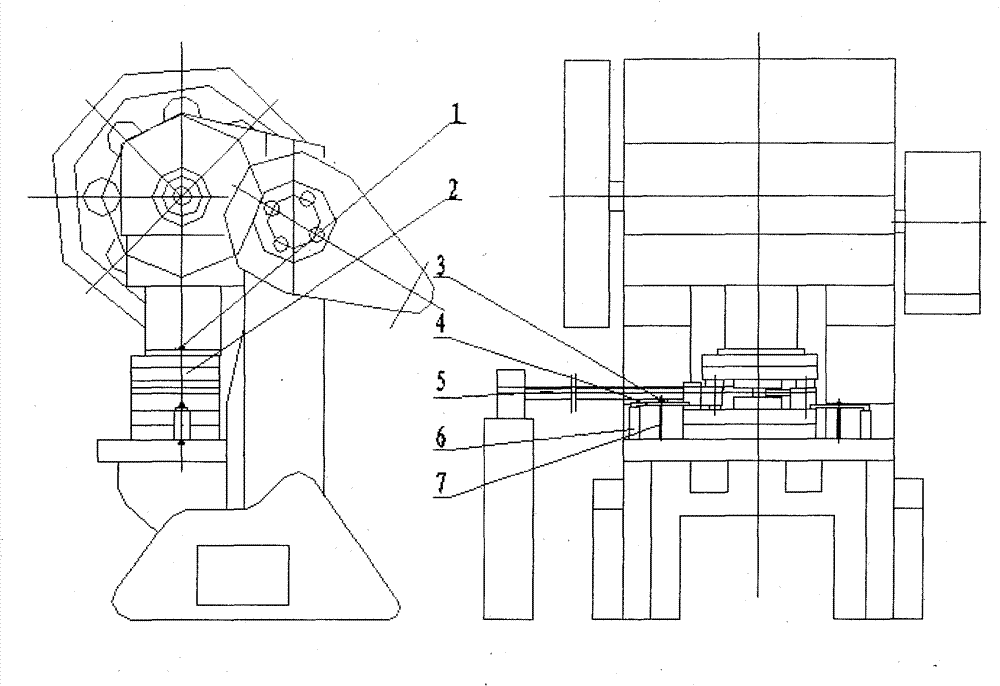

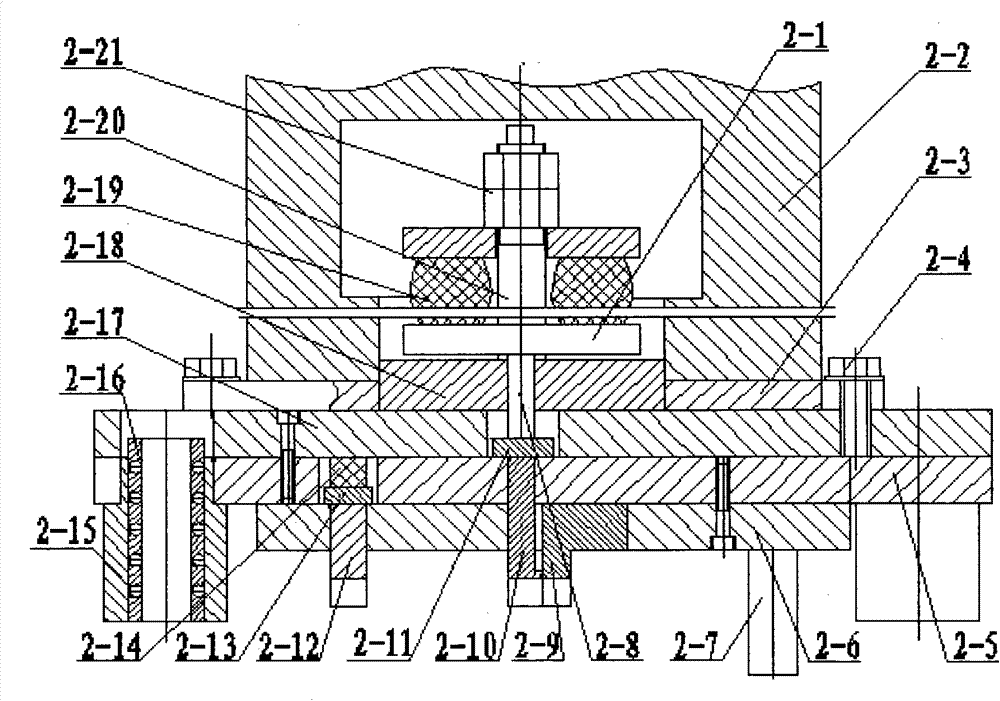

[0033] The shearing device of the present application includes an upper mold assembly, a lower mold assembly and an electric control device, which realize cutting of pipes through relative staggered shearing of the upper scissors and the lower scissors. The upper scissors are installed in the upper die assembly, and the lower scissors are installed in the lower die assembly; combined Figure 9 , the lower mold assembly is fixedly installed on the working table of the press, and the upper mold assembly is fixedly installed on the slide block of the press.

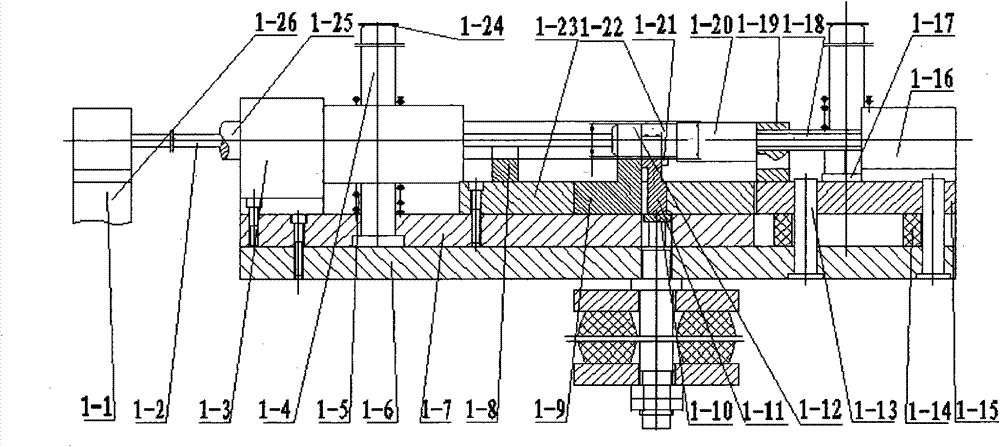

[0034] figure 1 and figure 2 Shown is the structural diagram of the lower mold assembly and the upper mold assembly.

[0035] Combine below figure 1 , Figure 5 and Image 6 Description of the lower mold assembly:

[0036] figure 1 Among them, the lower mold assembly includes the lower mold part and the feeding part. The lower mold part includes the lower template 1-7, the lower backing plate 1-6, the lower mold fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com