Steel cable prestressed glass curtain wall

A glass curtain wall and prestressing technology, applied in the direction of walls, building components, buildings, etc., can solve the problems that courtyards or corridors cannot be included in the shielding range of the outer protective structure, and achieve compact structure, increased permeability, and energy saving resource effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

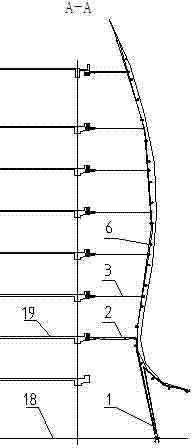

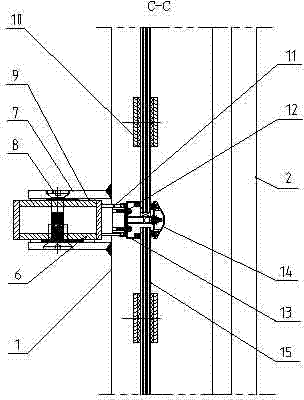

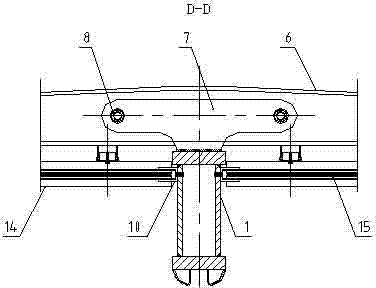

[0019] according to Figure 1~2 The specific structure of the present invention will be described in detail. The steel cable prestressed glass curtain wall includes glass 15 as a surface material, and a prestressed support system composed of an assembled steel structure and tensioned cables by a tensioner. Among them, the assembled steel structure is mainly assembled by prestressed steel beams 1, vertical tie rods 5, and transverse steel beams 6. The specification and shape of the prestressed steel beam 1 shall be determined according to the set prestressing requirements according to actual needs and possibilities. The prestressed steel beam 1 of this embodiment adopts an arc-shaped steel column structure, and its cross-sectional shape can be designed as an approximate box-shaped body (such as Figure 5 Shown), can also be designed as H-type or I-type cross-sectional shape. If it needs to cooperate with LED lamps, the front end of the prestressed steel beam 1 can be provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com