A system for testing the performance and energy efficiency of air compressors under simulated all-weather conditions

An air compressor, all-weather technology, applied in the direction of pump testing, mechanical equipment, machines/engines, etc., can solve the problems that cannot meet the urgent needs of energy efficiency testing, cannot realize all-weather working conditions testing, and has no energy efficiency testing function, etc., reaching a wide range of regions The effects of adaptability, test range expansion, and low system integration cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

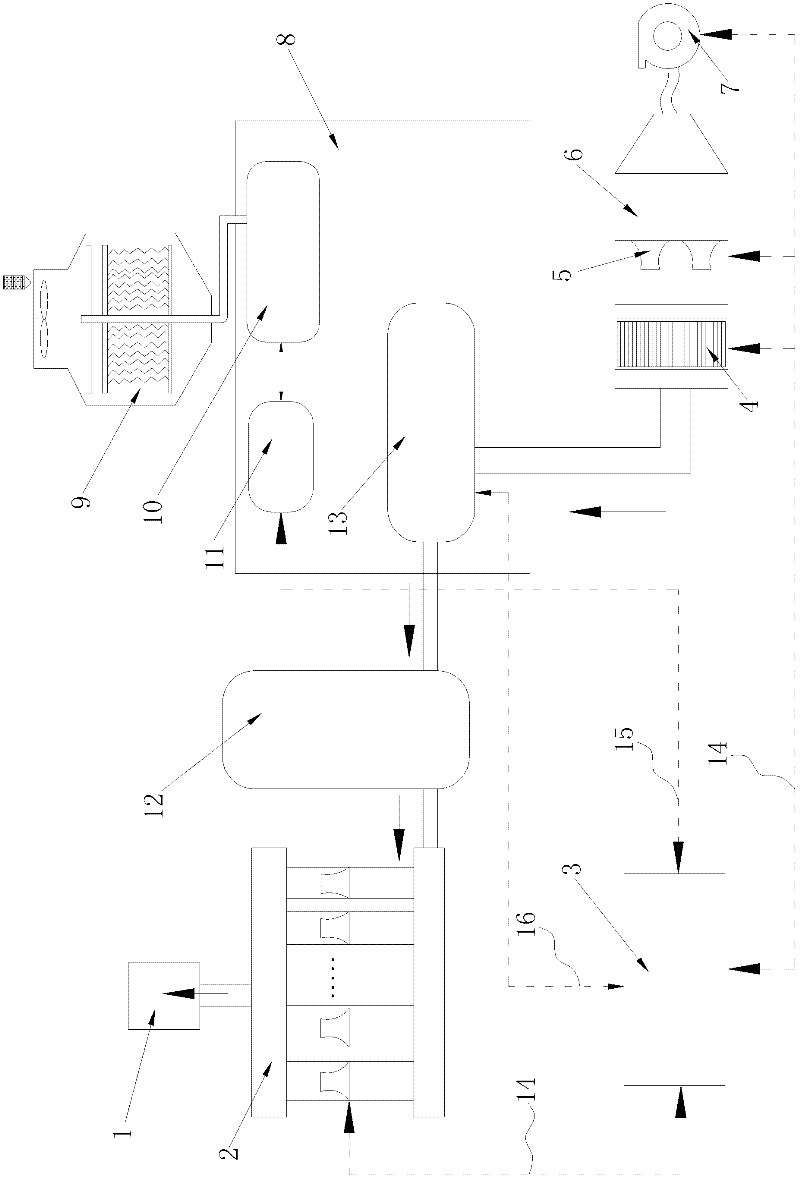

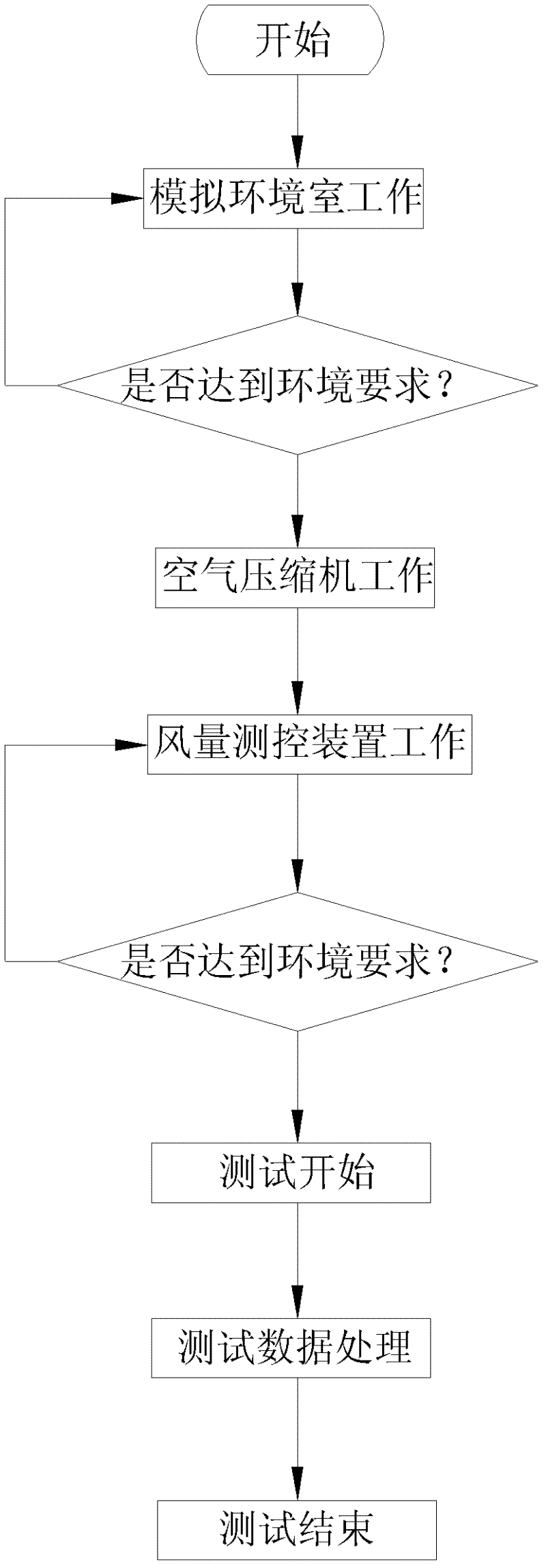

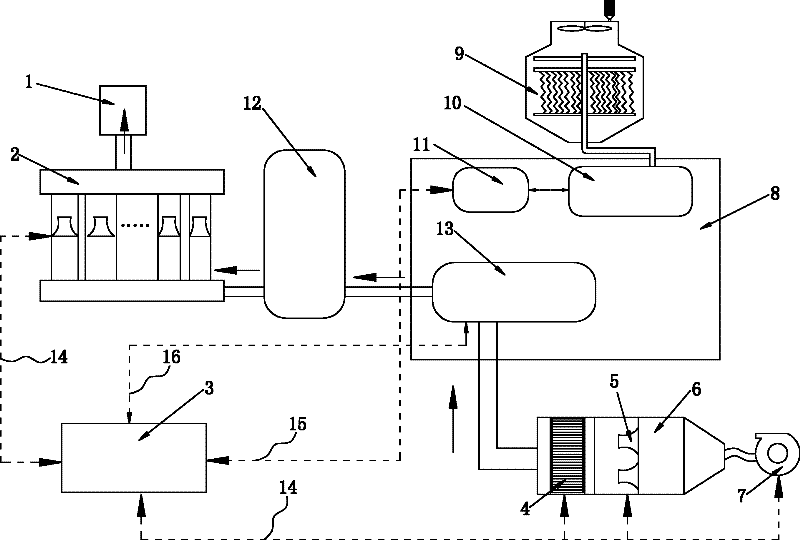

[0012] The present invention will be further described below according to the accompanying drawings.

[0013] Such as figure 1 As shown, the air compressor 13 is placed in the simulated environment chamber 8, the simulated environment chamber 8 is provided with a heat-insulated environment chamber, an indoor air-conditioning system 10 and an air-conditioning controller 11, so that the air compressor 13 can operate under different ambient temperatures and humidity. working conditions. It is automatically controlled by the control center unit 3 to meet various temperature and humidity requirements required by the test.

[0014] The air inlet of the air compressor 13 is connected to the air outlet of the air volume measurement and control device 6. The air volume measurement and control device 6 has a built-in air chamber environment control unit 4 and an automatic nozzle device 5. The front end of the air volume measurement and control device 6 is connected to the frequency con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com