A large format led light box

A LED light box and large-format technology, applied to lighting and heating equipment, instruments, mechanical equipment, etc., can solve the problems of high maintenance costs, complicated repairs, and inability to make LED light boxes, and achieve the effect of convenient transportation and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

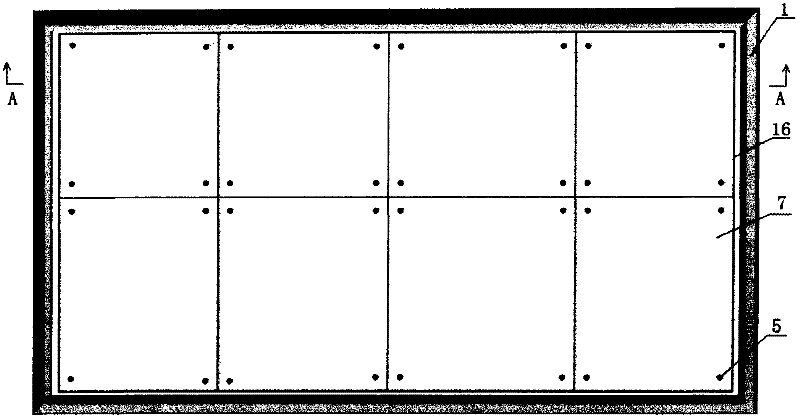

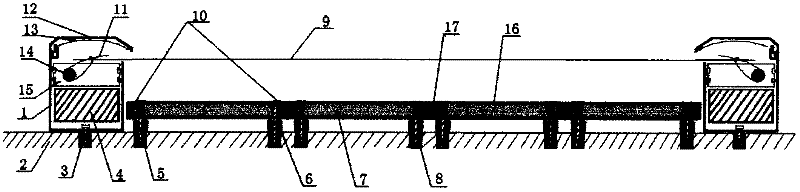

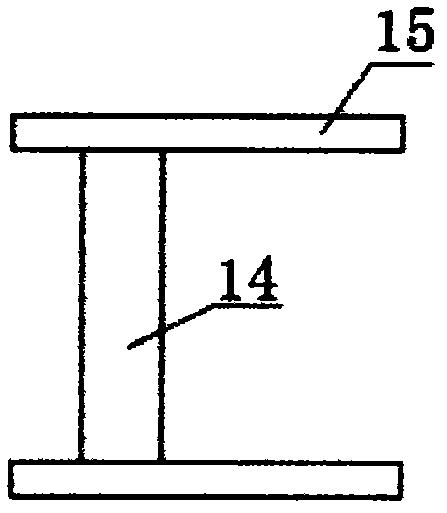

[0019] The large-format LED light box of this embodiment includes a metal frame 1 and a light guide plate 16. The light guide plate 16 is formed by splicing and combining a plurality of light guide units 7, and grooves 17 are arranged on both sides of each light guide unit 7. The slot 17 is embedded with an LED light strip 10, and the corner of each light guide unit 7 is fixed on the wall 2 with the first fixing screw 5, and the part where the first fixing screw 5 goes deep into the wall 2 is covered with an expansion tube 8 , the metal frame 1 is arranged around the light guide plate 16, the metal frame 1 is fixed on the wall 2 by the second fixing screw 3, the metal frame 1 is provided with a transformer adapter 4 and a movable pendant 15, and the transformer adapter 4 is bonded On the metal frame 1, the groove of the movable pendant 15 is connected with the protruding part of the metal frame 1. The movable pendant 15 is provided with a fixed rod 14, and the light box cloth 9...

Embodiment 2

[0022] The difference between this embodiment and Embodiment 1 is that the distance between the light box cloth 9 and the light guide plate 16 is 35 mm.

Embodiment 3

[0024] The difference between this embodiment and Embodiment 1 is that the distance between the light box cloth 9 and the light guide plate 16 is 50 mm.

[0025] The LED light boxes of the above embodiments solve the problem that large-format light boxes cannot be produced in the prior art by splicing single small-area light guide units into required large-format light guide plates. A single small-area light guide unit can be transported to the site for on-site installation and construction, which is very convenient for transportation and construction, and the transformer adapter and movable pendant are installed in the metal frame, which also facilitates daily maintenance and replacement of light boxes It is convenient for deployment and also solves the problem of the storage location of the transformer adapter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com