Explosion-proof door structure of oil-fired boiler

A technology for oil-fired boilers and explosion-proof doors, which is applied to the doors of combustion chambers, combustion chambers, combustion methods, etc., can solve the problem that explosion-proof doors cannot achieve explosion-proof effect, furnace explosion damage cannot be effectively reduced, and explosion-proof doors cannot be set in the furnace. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

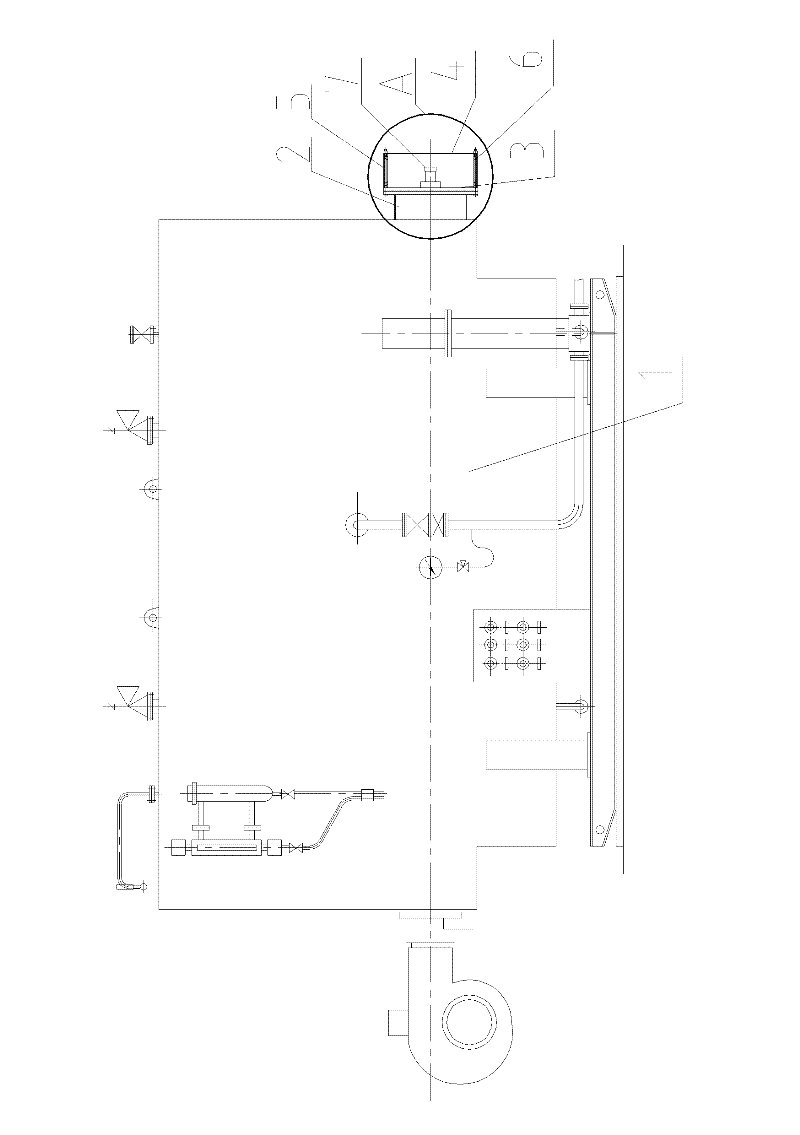

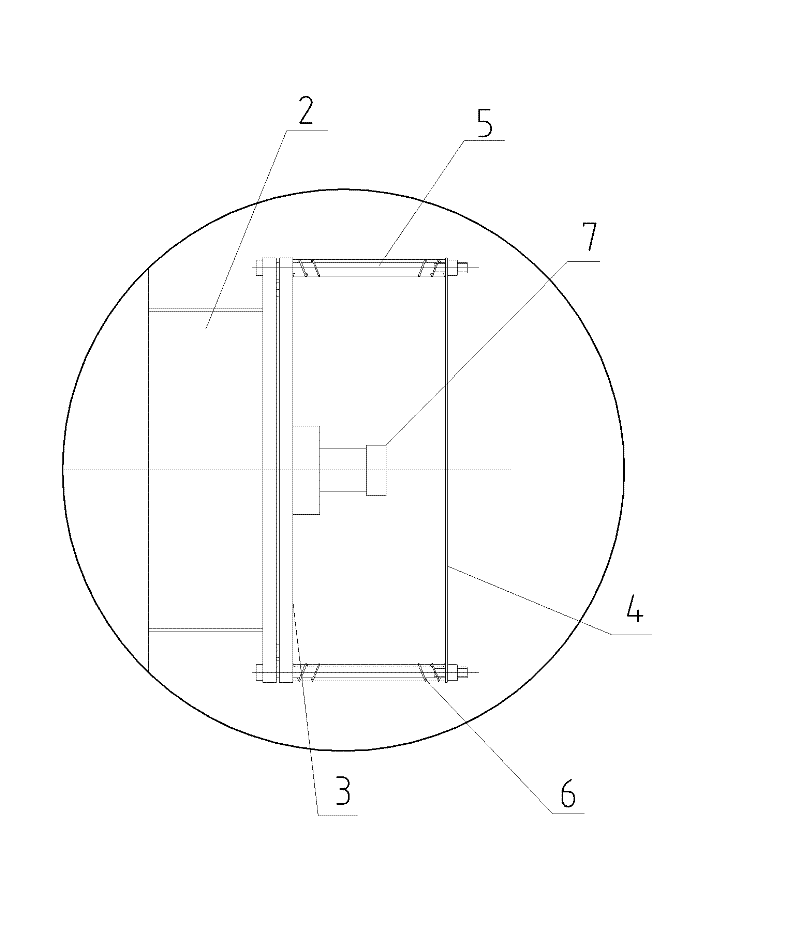

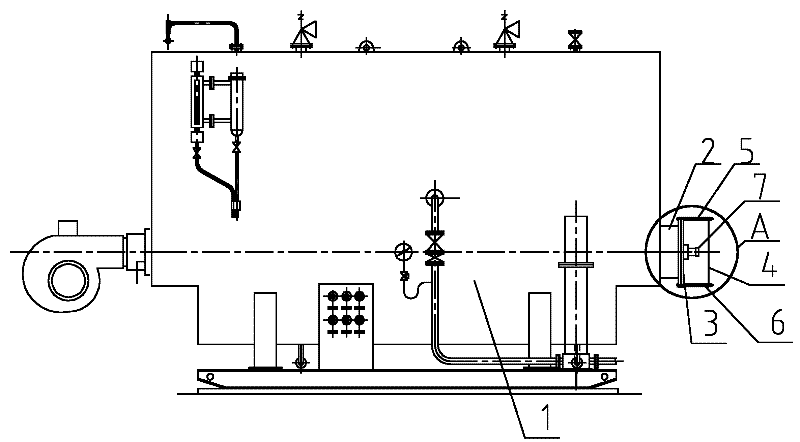

[0010] See figure 1 , figure 2 , which includes a boiler furnace 1, the tail of the boiler furnace 1 protrudes from the explosion-proof door installation pipe 2, the explosion-proof door 3 is packaged in the outer pipe opening of the explosion-proof door installation pipe 2, and the outer end surface of the explosion-proof door 3 is provided with an explosion-proof door stop flat Steel ring 4, explosion-proof door 3, and explosion-proof door stopper flat steel ring 4 have pin installation holes at corresponding positions, and pin shaft 5 corresponds to the pin shaft installation that runs through the corresponding positions of explosion-proof door 3 and explosion-proof door stopper flat steel ring 4 hole, the compression spring 6 is set on the part of the pin shaft between the explosion-proof door 3 and the explosion-proof door stop flat steel ring 4, and the two ends of the compression spring 6 are installed on the outer end surface of the explosion-proof door 3 and the expl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com