A performance testing method and device for a plastic screw cap

A testing device and performance technology, applied in the direction of applying stable tension/pressure to test material strength, etc., can solve problems such as no unified requirements, inability to reflect the process, and uncertain testing of similar products to achieve high operability and structure Novel, data-accurate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, the present invention will be further described as follows:

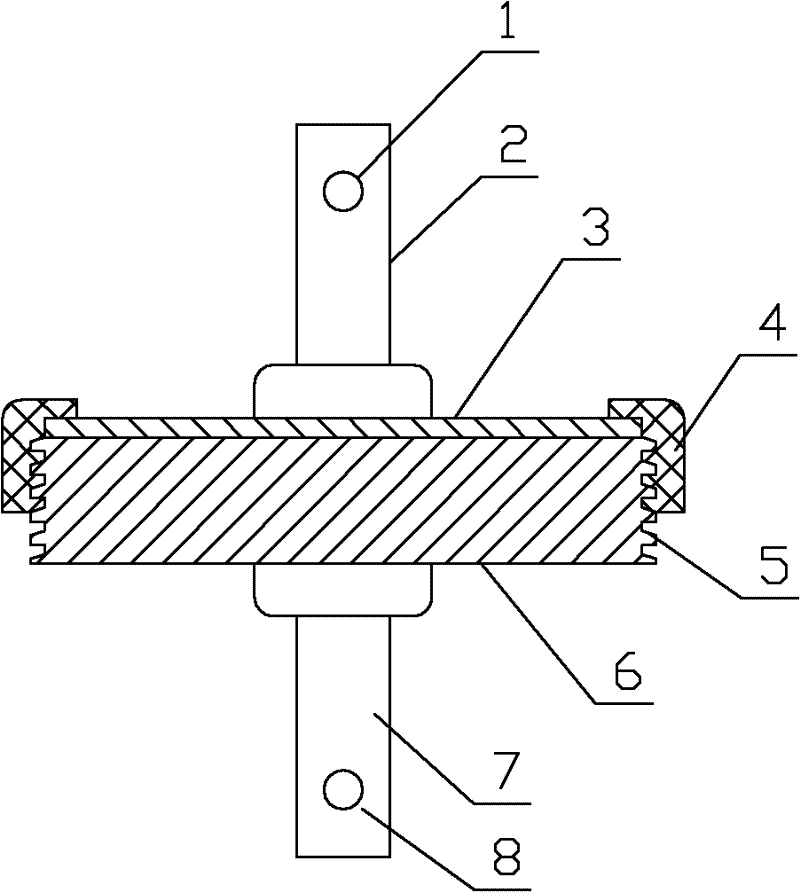

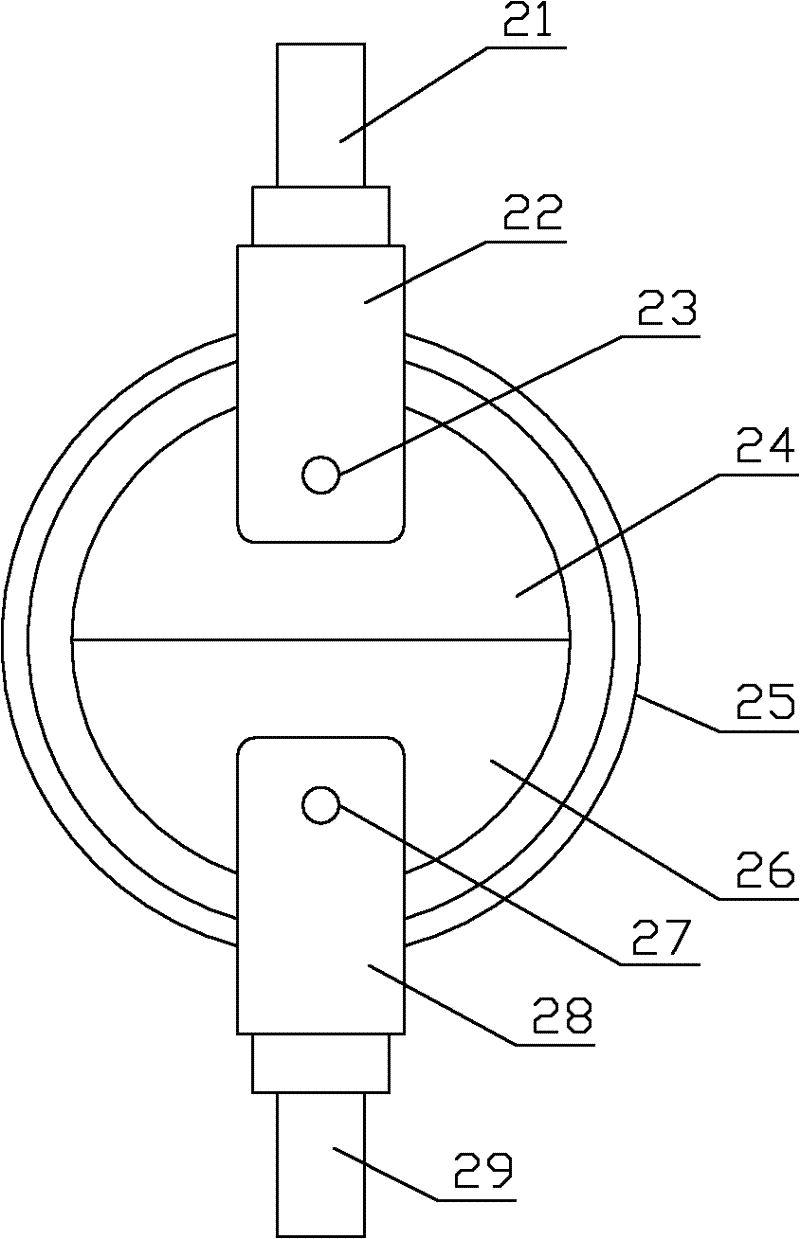

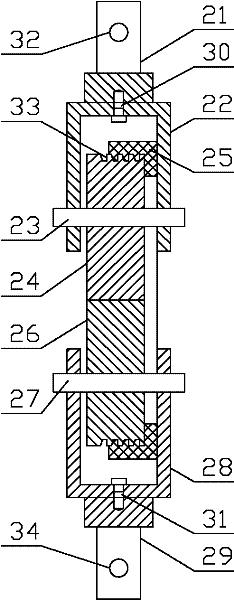

[0029] As shown in the accompanying drawings, the testing device of the present invention includes: a vertical performance testing device and a horizontal performance testing device, and the vertical performance testing device includes an upper connection conversion head 2, an upper drawing die 3, a lower drawing die 6 and a lower Connect the conversion head 7, the upper drawing die 3 is a cylindrical structure, the upper end face of the upper drawing die 3 is connected to the upper connection conversion head 2, the lower end face of the upper drawing die 3 is connected to the lower die 6, and the lower die 6 is Cylindrical structure, the side of the pull-down die 6 is provided with an external thread 5 that matches the detection plastic screw cap, the lower end of the pull-down die 6 is connected to the lower connection adapter 7; the horizontal direction perfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com