A method for testing moisture content in pole pieces

A test method and moisture technology, which is applied in the direction of chemical method analysis, measuring devices, and analysis materials, can solve the problems of large differences in parallel test results, and achieve the effect of simple and convenient operation and accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

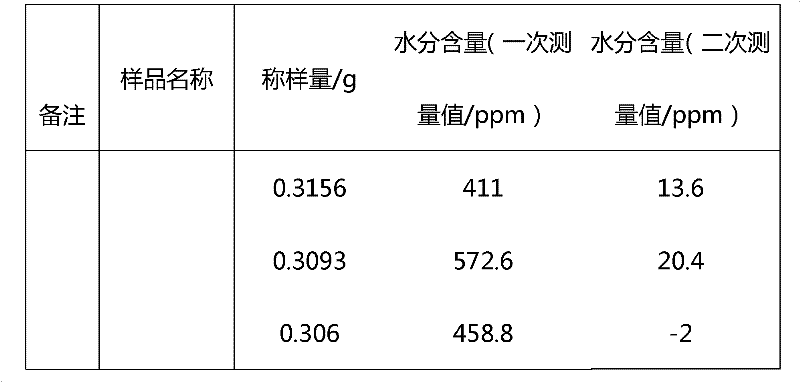

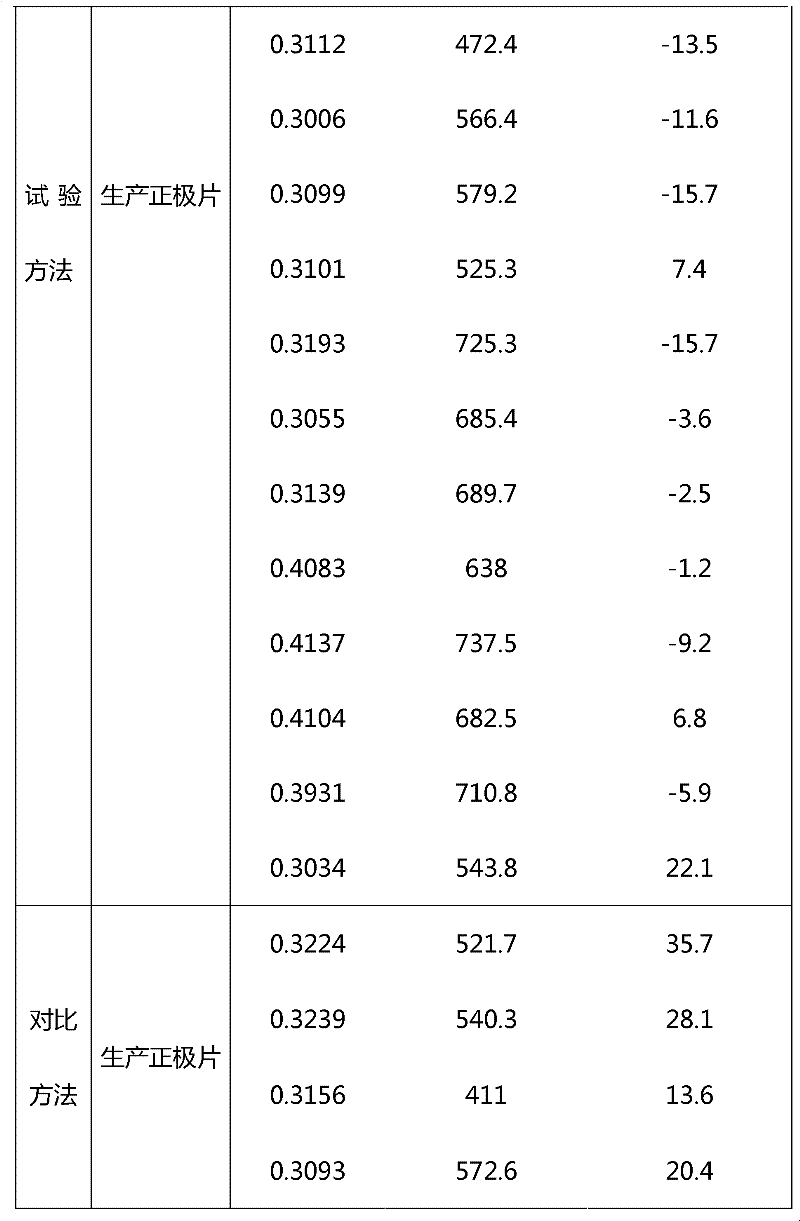

Image

Examples

Embodiment 1

[0019] A method for testing moisture content in a pole piece, which is tested by a Karl Fischer moisture tester, and the specific steps are:

[0020] (1) Dry the sample bottle in an oven at 120°C for 3 hours to remove the moisture in the sample bottle to reduce the background value of the instrument and the interference to the sample test value;

[0021] (2) Put the electrode piece into the dried sample bottle, seal it and place it in an oven for pre-baking at 145°C for 30 minutes;

[0022] (3) Put the pre-baked sample bottle into a heating furnace at 170°C quickly for testing. The test method is that the water vapor baked out enters the reaction kettle with the dry carrier gas and I 2 A quantitative chemical reaction takes place, according to the consumption of I 2 Calculate the amount of moisture involved in the reaction, so as to obtain the moisture content value in the pole piece.

Embodiment 2

[0024] A method for testing moisture content in a pole piece, which is tested by a Karl Fischer moisture tester, and the specific steps are:

[0025] (1) Dry the sample bottle in an oven at 120°C for 3 hours to remove the moisture in the sample bottle to reduce the background value of the instrument and the interference to the sample test value;

[0026] (2) Put the electrode piece into the dried sample bottle, seal it and place it in an oven for pre-baking at 140°C for 35 minutes;

[0027] (3) Put the pre-baked sample bottle into a heating furnace at 170°C quickly for testing. The test method is that the water vapor baked out enters the reaction kettle with the dry carrier gas and I 2 A quantitative chemical reaction takes place, according to the consumption of I 2 Calculate the amount of moisture involved in the reaction, so as to obtain the moisture content value in the pole piece.

Embodiment 3

[0029] A method for testing moisture content in a pole piece, which is tested by a Karl Fischer moisture tester, and the specific steps are:

[0030] (1) Dry the sample bottle in an oven at 120°C for 3 hours to remove the moisture in the sample bottle to reduce the background value of the instrument and the interference to the sample test value;

[0031] (2) Put the electrode piece into the dried sample bottle, seal it and place it in an oven for pre-baking at 130°C for 40 minutes;

[0032] (3) Put the pre-baked sample bottle into a heating furnace at 170°C quickly for testing. The test method is that the water vapor baked out enters the reaction kettle with the dry carrier gas and I 2 A quantitative chemical reaction takes place, according to the consumption of I 2 Calculate the amount of moisture involved in the reaction, so as to obtain the moisture content value in the pole piece.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com