Air Gap Variation Mechanism of Radial Flux Motor

A magnetic flux and air gap technology, applied in the direction of machines/engines, engines, wind turbines, etc., can solve the problems of radial flux motor air gap variable technology content shortage, etc., to reduce the resonance effect and reduce the start-up wind speed , the effect of slowing down the force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

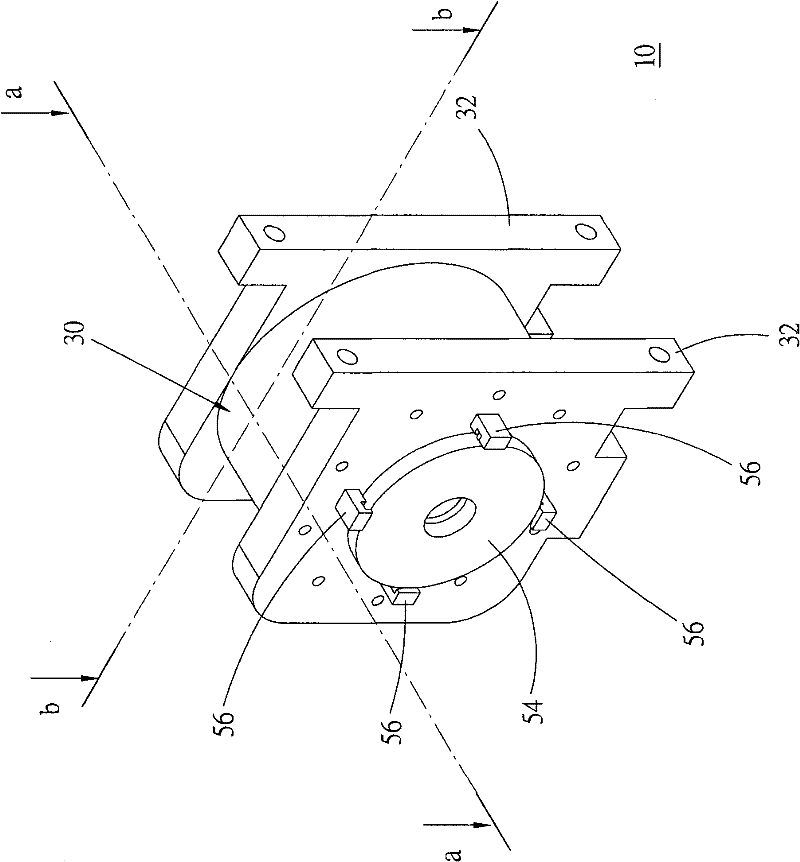

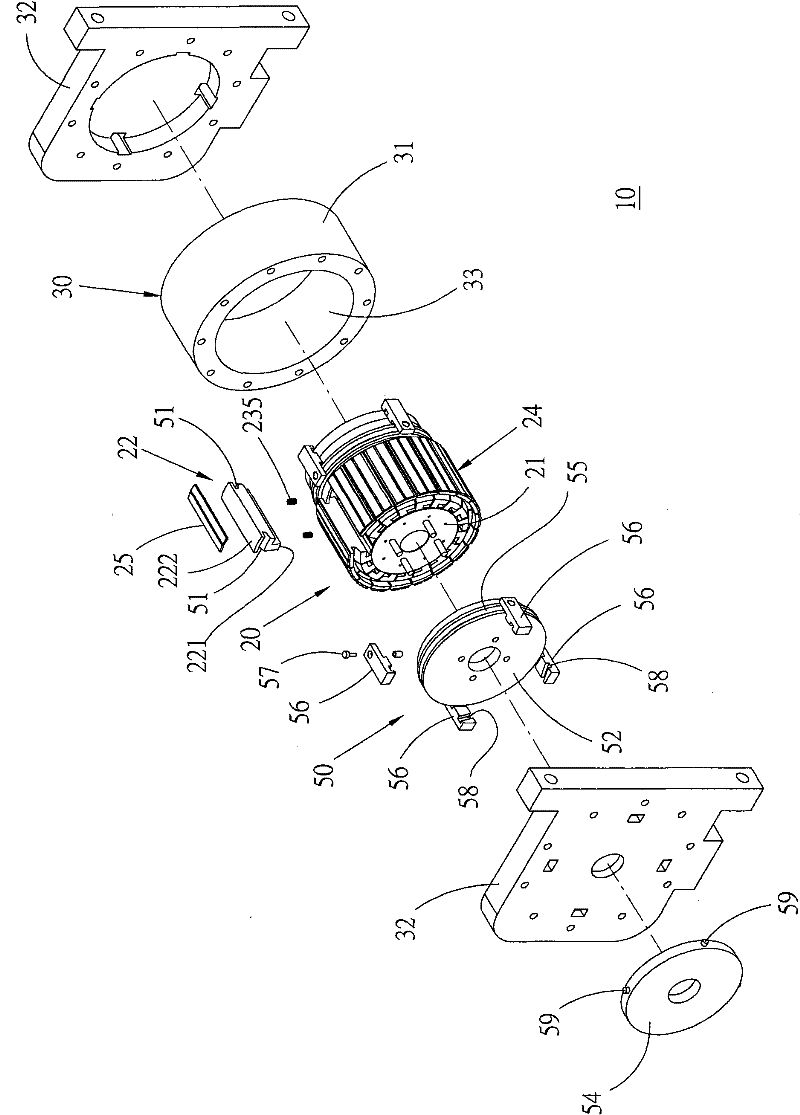

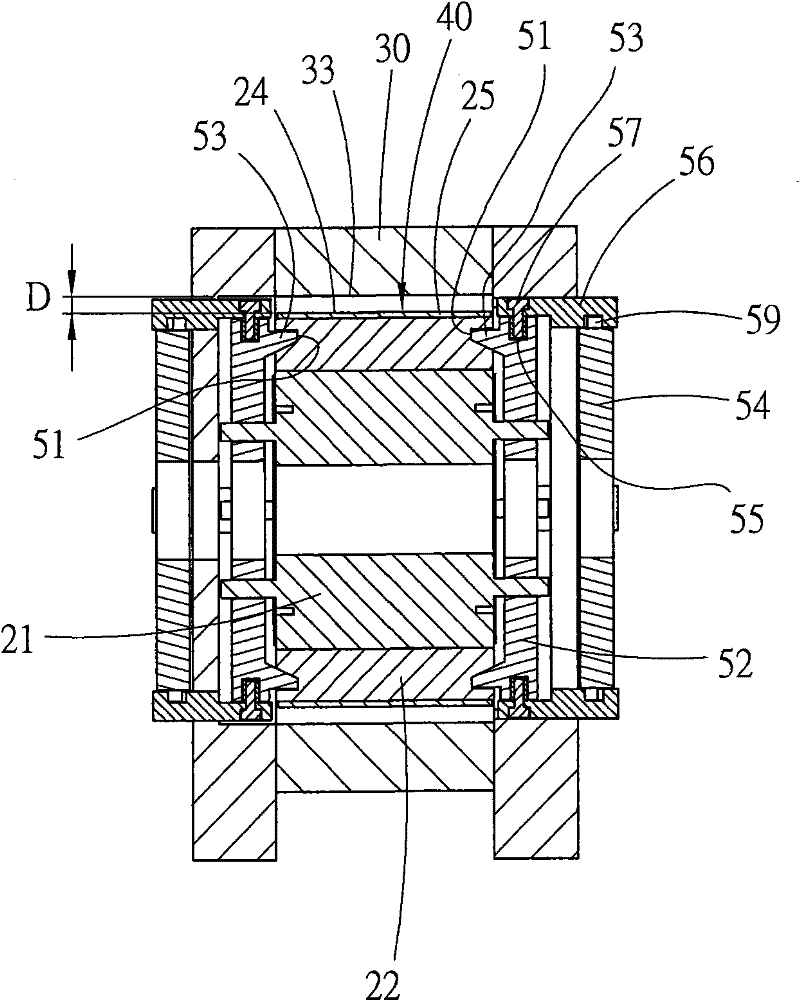

[0033] Please refer to the figures shown, the air gap variable mechanism 10 of the radial flux motor provided in a preferred embodiment of the present invention, it is the inner rotor generator as its specific technical content, and the constituent elements It is mainly composed of a first sub-component 20 as a rotor, a second sub-component 30 as a stator, an annular air gap 40 and a driving part 50 .

[0034] The first sub-part 20 has a first sub-body 21 that is generally columnar, and several diameter-reducing parts 22 formed by elongated sliders that are arc-shaped in cross-section are coaxial and parallel to the first sub-body with the center of curvature. The way of the shaft of the body 21 is that one end 221 is combined on the peripheral side of the first body 21 by a joint part 23, so that the diameter-reducing parts 22 are adjacent to each other, and the diameter-reducing parts 22 can be connected to each other. The convex arc surfaces 222 are connected to each other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com