Construction method for water and gas distributing system of filter pool

A technology of water distribution and air distribution, construction method, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of air-water flushing interference, influence of bottom plate fixing bolts, difficulty in ensuring horizontal position, etc. The effect of avoiding air and water flushing interference and facilitating installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

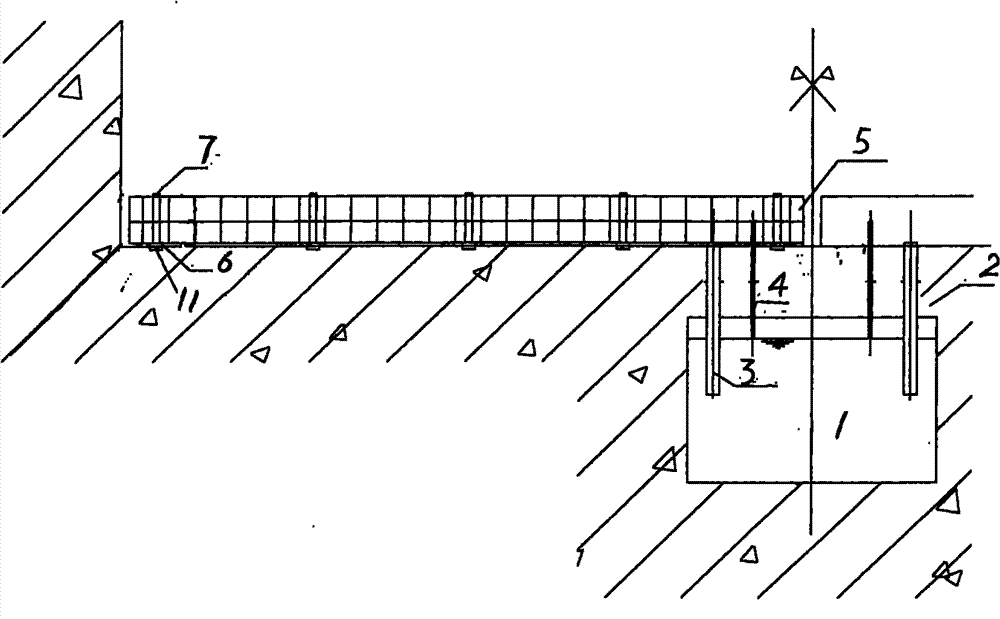

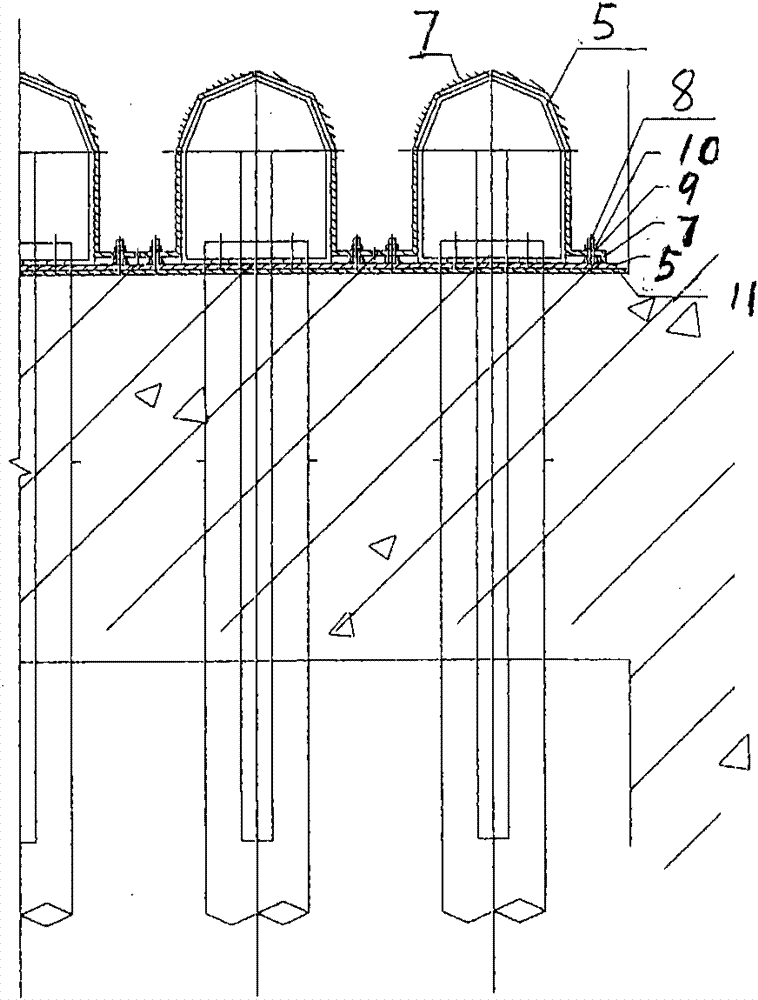

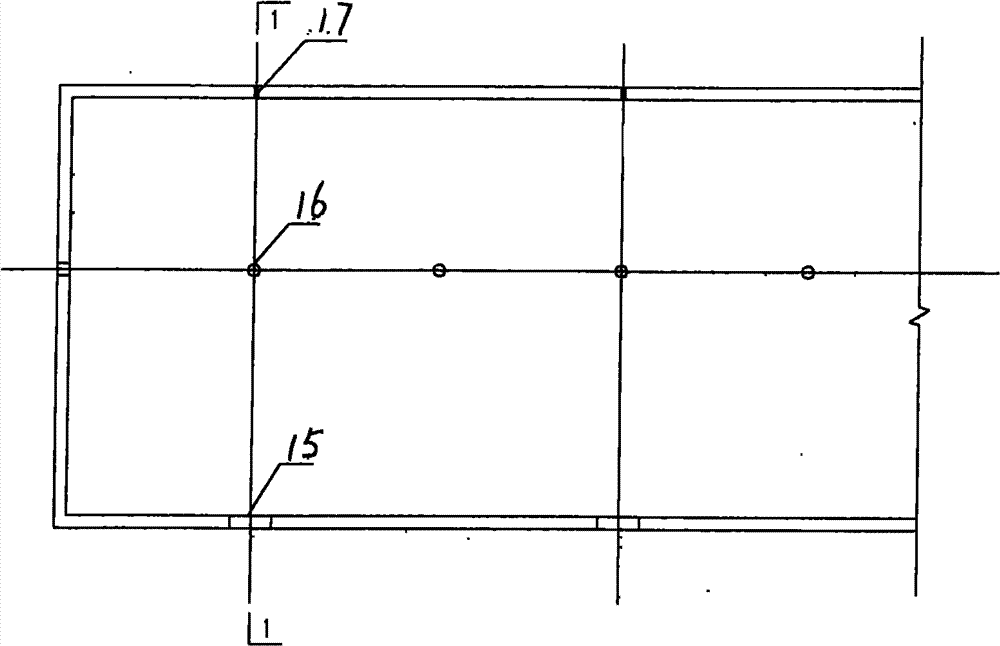

[0012] The present invention mainly includes a water distribution and air distribution canal 1 located at the lower part of the air-water backwashing filter tank, the canal roof 2 is implemented together with the water distribution riser 3 and the gas distribution riser 4 during civil construction, and the filter tank bottom plate is poured and rammed The pre-buried scouting plate 11 has been pre-buried to ensure that the bottom of the pool is flat and poured in place at one time, and then the secondary scooping plate 6 is welded to the upper part of the pre-buried scouting plate 11 to ensure the leveling of the horizontal pipe 5 for water distribution and gas distribution, and the secondary scooping plate 6 Weld the bolts 8 with nuts, set the horizontal pipe 5 for water distribution and air distribution on the upper part of the secondary leveling plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com