High Strength Straight Shank Twist Drill

A twist drill and high-strength technology, applied in the field of cutting tools, can solve the problems of reduced tool life, accelerated component wear, and easy fracture, and achieve the effect of improving production efficiency and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

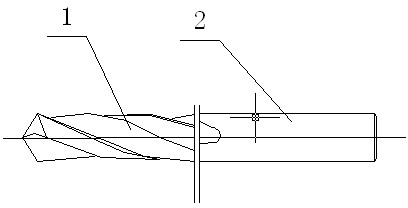

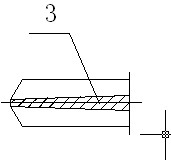

[0013] The present invention includes a shank 2 and a blade 1, the core thickness 3 of the blade 1 is 50% smaller than that of the standard drill bit, and the core thickness increment is twice as large as that of the standard drill bit.

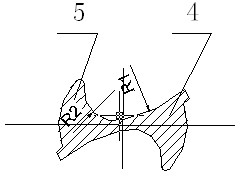

[0014] The chip flute of the cutting edge 1 of the present invention includes a chip inlet 4 with a large R at the front and a chip breaker 5 with a small R at the rear. The chip-feeding groove 4 of the present invention has fast chip removal and quickly takes away the cutting heat, and the rear chip-breaking groove 5 enhances the cutting ability, and the iron chips are smoothly discharged from the groove.

[0015] The fan-shaped plate 7 of the present invention is made up of large and small double R and angle lines. Install two fan-shaped plates 7 designed according to high-strength straight-shank twist drills and two back plates 6 on the head frame of the four-roll rolling mill. The four plates form a certain angle with each other, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com