Tires with additional cap plies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

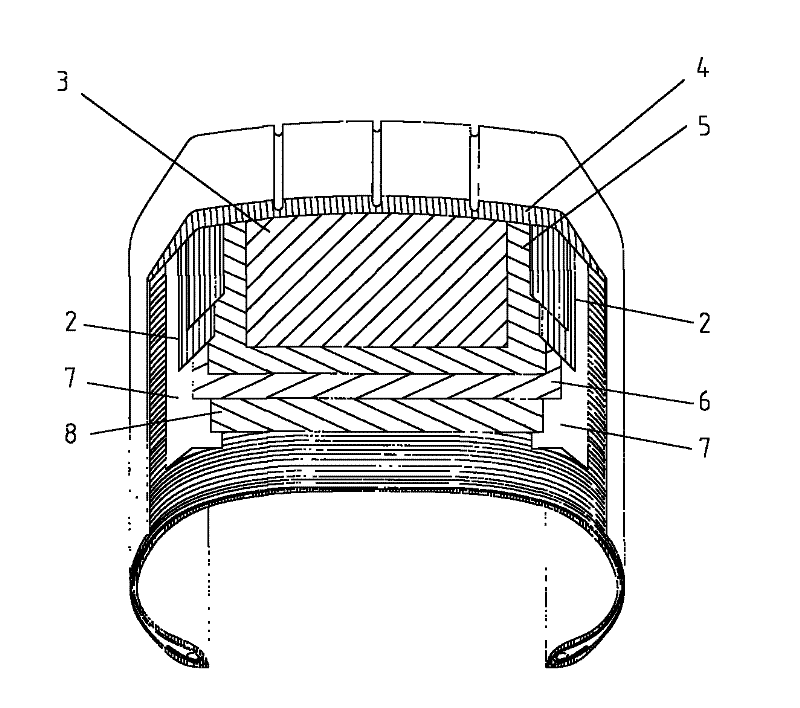

[0034] Example 1, such as Figure 1 to Figure 3 As shown, a tire with an additional cap layer includes a tread rubber 4, a fourth belt layer 3, a third belt layer 5, a second belt layer 6, and a pair of sidewalls sequentially from the crown to the rim Pad rubber 7 and first belt layer 8.

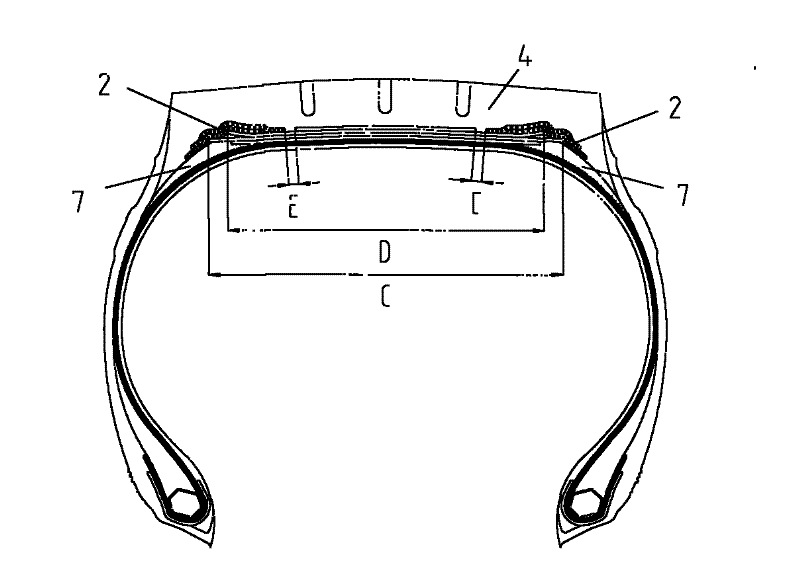

[0035] Wherein, between the pad rubber 7 , the two sides of the third belt layer 5 and the tread rubber 4 , an additional cap layer 2 is lined respectively.

[0036] That is, on both sides in the tire circumferential direction, the additional cap layer 2 is wound on the sides of the third belt layer 5 and the second belt layer 6 at 360° respectively.

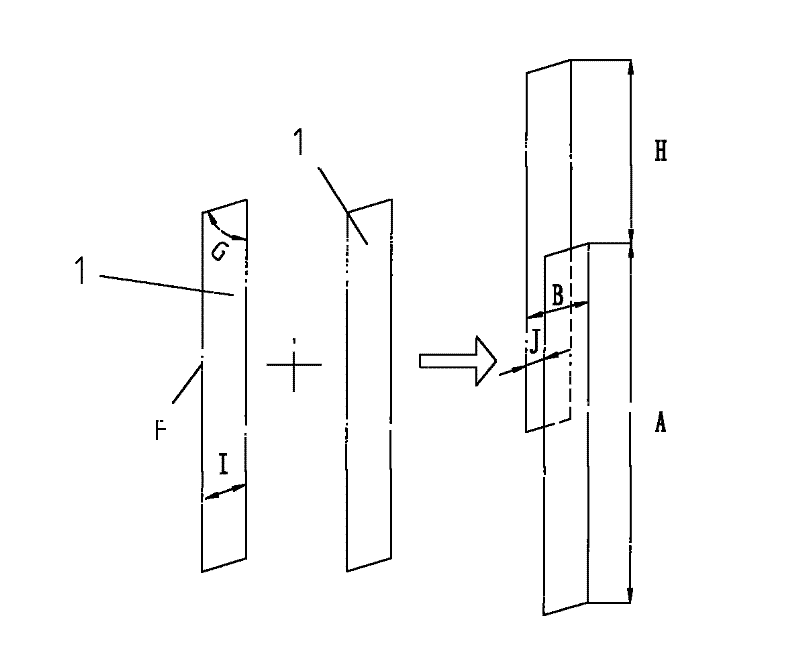

[0037] The additional cap layer 2 is formed by lapping two layers of nylon plies 1, the nylon cords in each nylon ply 1 are kept parallel to the side F, and the longitudinal cutting angle G of the nylon plies 1 is ≤ 90°.

[0038] on the circumference of the tire,

[0039] Width of additional cap ply 2 after 2 layers of nylon plies 1 overl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com