With cassette and with printing unit

A technology with printing and cassettes, which is applied in the direction of printing devices, printing, ink ribbon cassettes, etc., and can solve the problems of tape core tilting, tape core shaking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 Embodiment approach

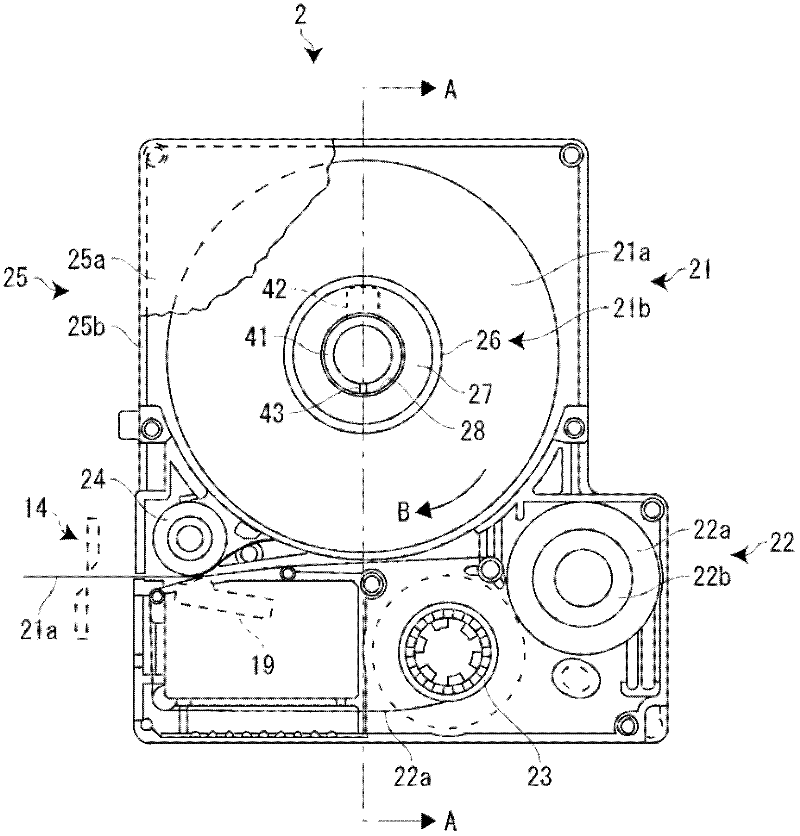

[0045] refer to Image 6 , the tape cassette 2 of the second embodiment will be described. In addition, descriptions similar to those of the first embodiment are omitted. Image 6 It is a plan view of the tape cassette 2 of the second embodiment in which the upper case 25a is omitted. In the tape cassette 2 of the second embodiment, the rotation guide portion 42 is arranged on the normal line of the position where the printing tape 21a is fed out and unwound. In this way, by providing the rotation guide 42 at the portion where the tilting force concentrates (the force applied is the largest), the belt core 21b can be reliably prevented from tilting, and stable rotation without "wobbling" can be ensured.

no. 3 Embodiment approach

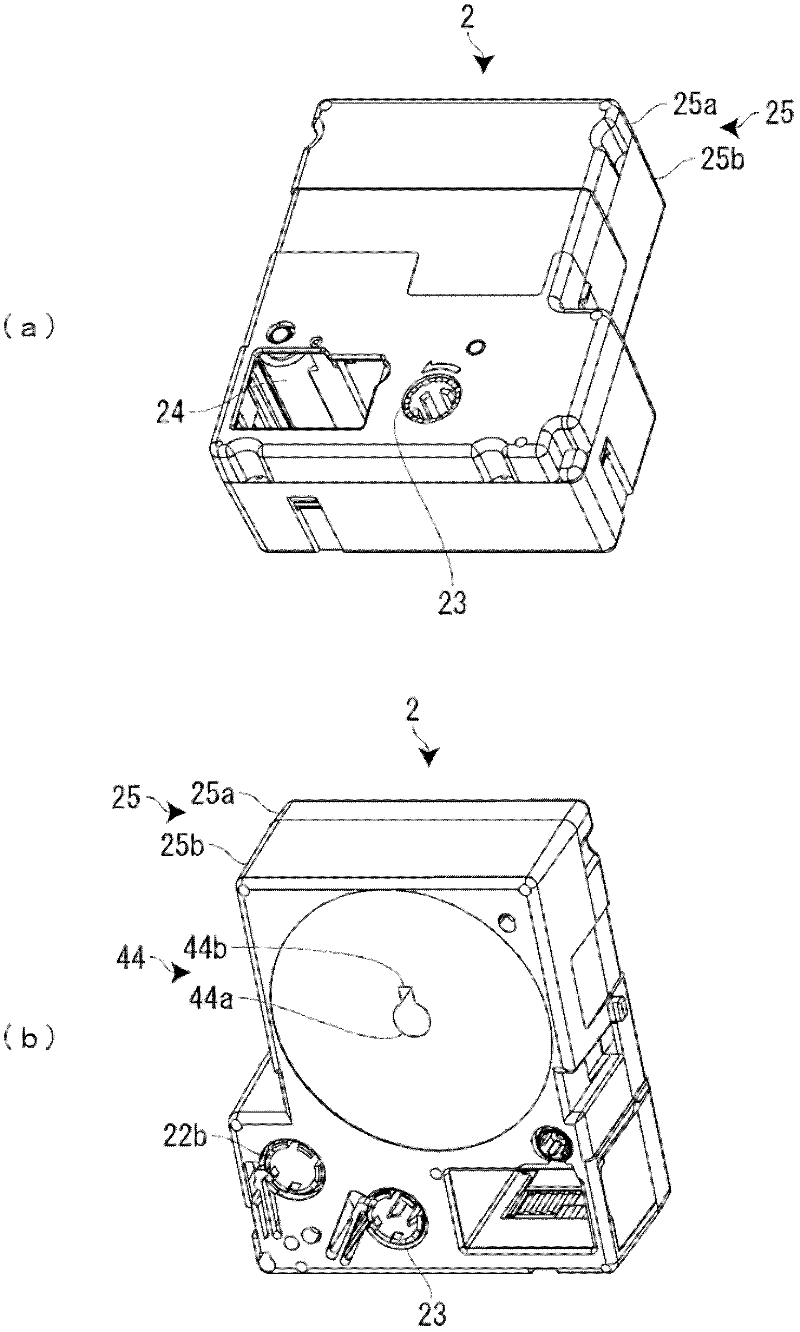

[0047] Figure 7 (a) is a plan view of the tape cassette 2 of the third embodiment. In addition, descriptions similar to those of the first embodiment are omitted. In this tape cassette 2 , a plurality of (four in this embodiment) rotation guide portions 42 are provided at equal intervals in the circumferential direction of the shaft support portion 41 . In this case, the number and positions of the rotation guides 42 are arbitrary. According to this configuration, the inclination of the tape core 21b in multiple directions can be prevented, and "wobbling" of the tape core 21b can be reliably prevented.

[0048] (Modification of the third embodiment)

[0049] Figure 7 (b) is a plan view of a tape cassette 2 according to a modified example of the third embodiment. In this tape cassette 2 , the rotation guide portion 42 is provided over the entire circumference of the shaft support portion 41 . According to this structure, the inclination of the tape core 21b can be preve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com