A combination grid

A technology of grid frame and steel structure beam is applied in the field of combined grid frame, which can solve the problems of complicated design and calculation, difficult to make template, difficult construction, etc., and achieve the effect of simplifying the calculation process and improving the calculation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The detailed structure of this patent will be further described below in conjunction with the accompanying drawings.

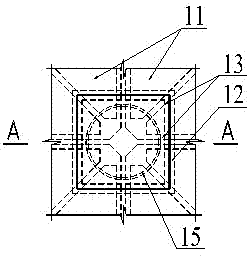

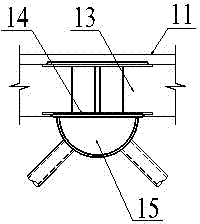

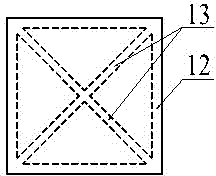

[0024] combine Figure 4 A combined grid structure shown includes an upper chord and a lower chord of the grid, the lower chord is welded below the upper chord, and the upper chord includes an integral concrete slab 1 and steel structural beams 2, the steel structural beams 2 are arranged in a cross. further combined Figure 5 , the steel structure beam 2 is a ⊥-shaped beam, the vertical part is embedded in the integral concrete slab 1, and the transverse part is arranged on the lower side of the integral concrete slab 1. The lower chord is the spherical segment node 5 of the steel structure, which is connected below the intersection position of the steel structure beams 2 through the top plate 4, and the web bar 6 is connected below. The structure of the node 5 is very simple, only need to weld the ⊥-shaped beam on the roof 2.

[0025] In the intern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com