Main Transformer Bushing Maintenance Platform

A technology for repairing platforms and bushings, which is applied to ladders, buildings, building structures, etc. It can solve problems that affect work efficiency, make it difficult to ensure the safety of workers, and make it difficult for insulated bucket trucks to reach the working position. It is easy to carry and secure Safety, anti-tilt effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

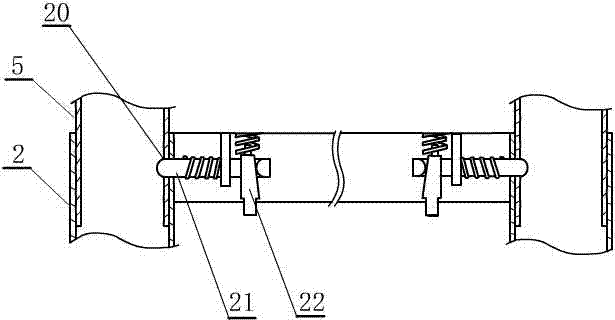

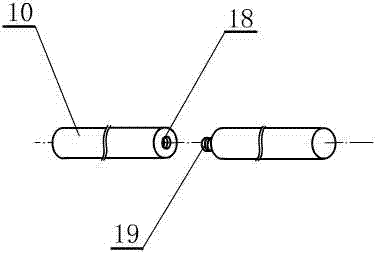

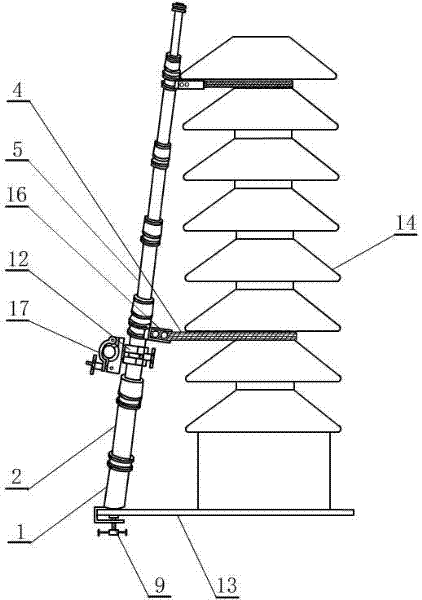

[0016] Such as Figure 1 to Figure 2 As shown, the main transformer bushing maintenance platform of the present invention includes a ladder foot 1 and at least two hollow ladder sections 5, and the ladder foot 1 and hollow ladder sections 5 include two hollow ladder tubes and are fixed to the ladder tubes on There is at least one step beam in one piece, the ladder body pipe 2 of the ladder foot 1 and the ladder body pipe 11 of the lowermost ladder section 5 and the joints of the ladder body pipes 11 of each ladder section are fitted together and form a sliding fit. The tread beam 6 of each ladder section 5 is hollow, and a locking device is provided between the ladder section tread beam 6 and the ladder body tube 11 of the ladder section. Inside, the vertical slope push rod 21 covered with a spring and the horizontal bolt 21 hinged on the slope push rod 21 and covered with a spring, the ladder body tube 11 of the ladder section is provided with a locking mechanism correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com