variable intake manifold

An intake manifold, variable technology, applied in combustion air/combustion-air treatment, internal combustion piston engine, engine components, etc., can solve the problem of constant pressure cavity volume and achieve the effect of high torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

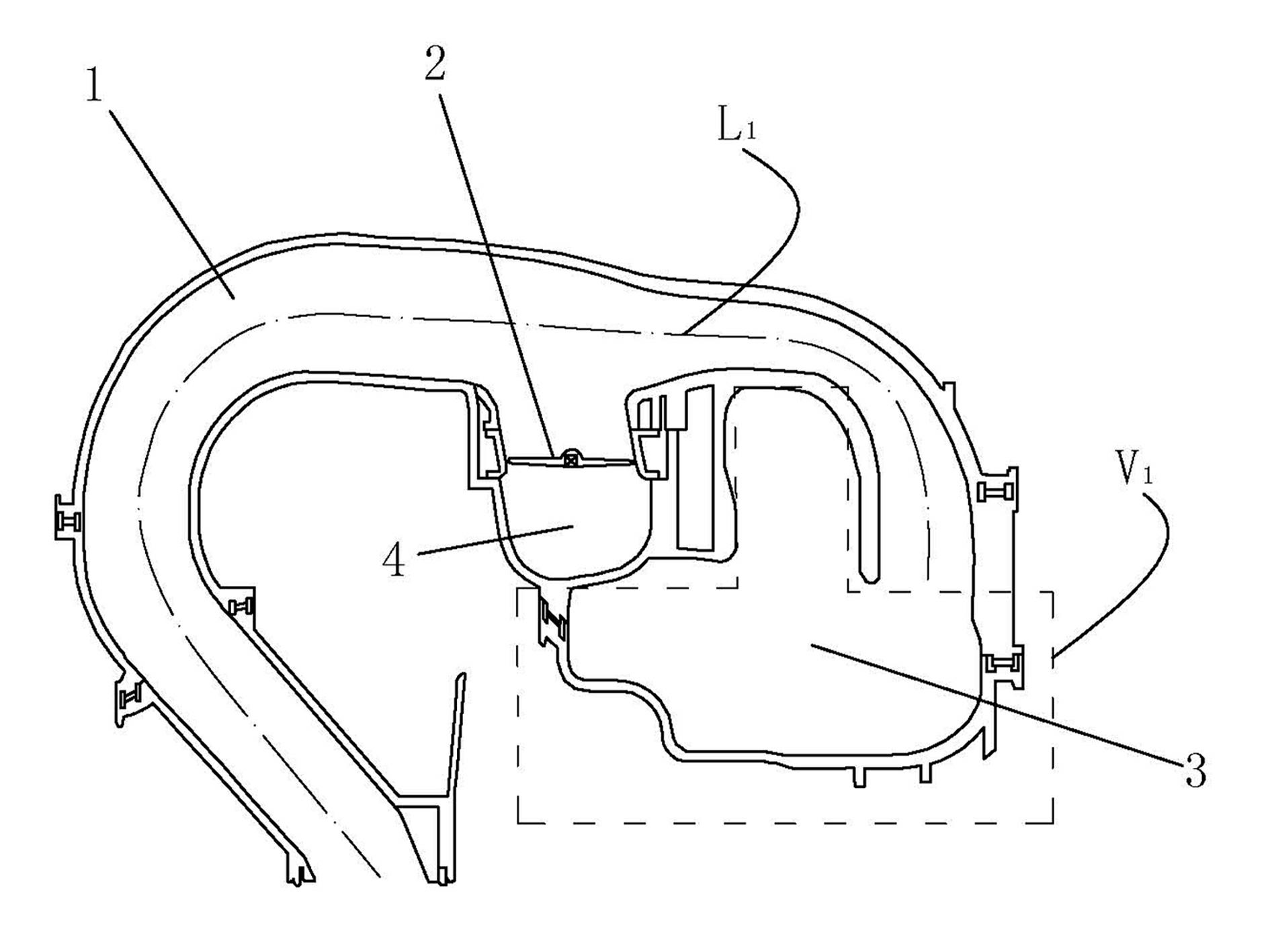

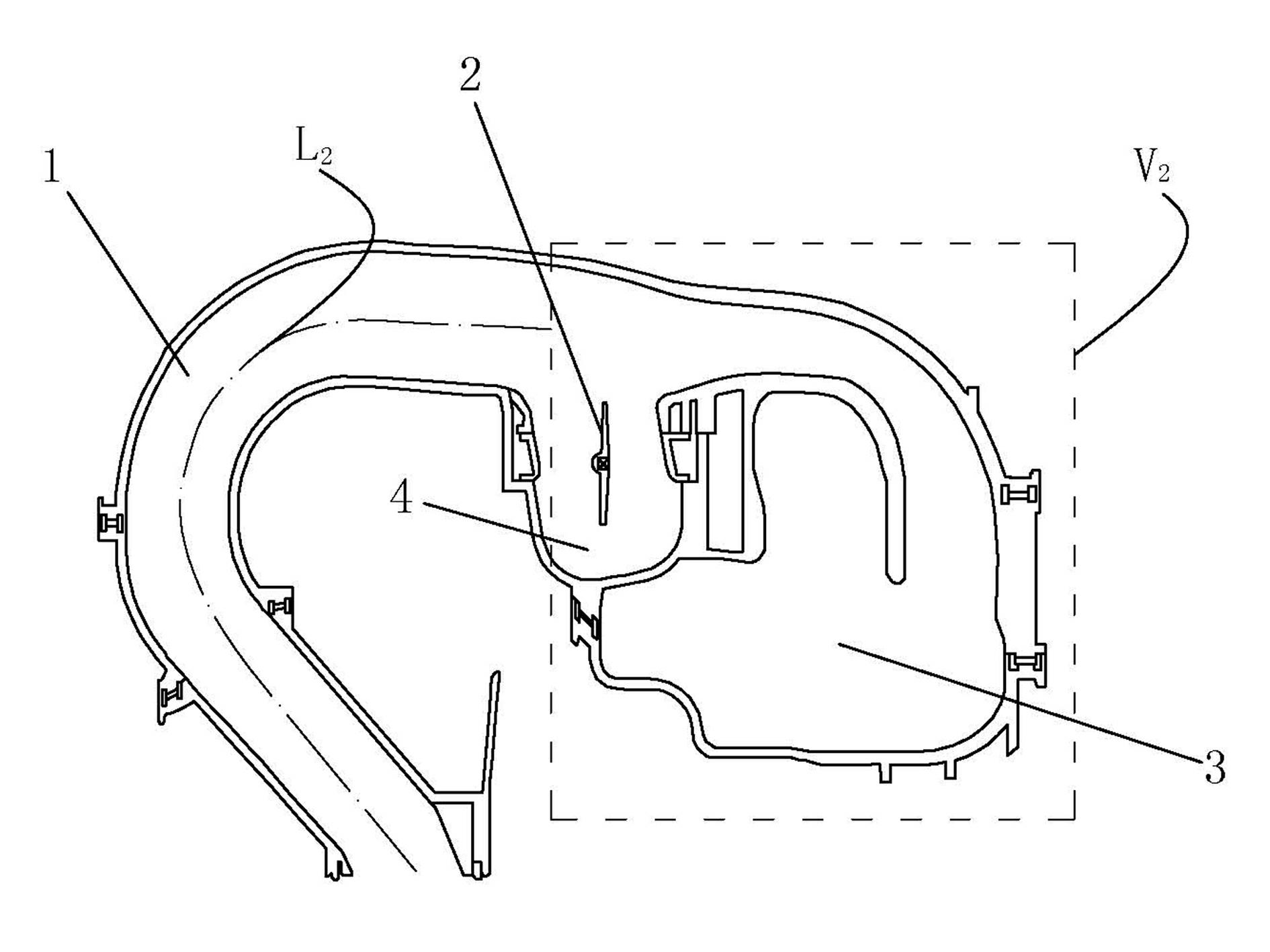

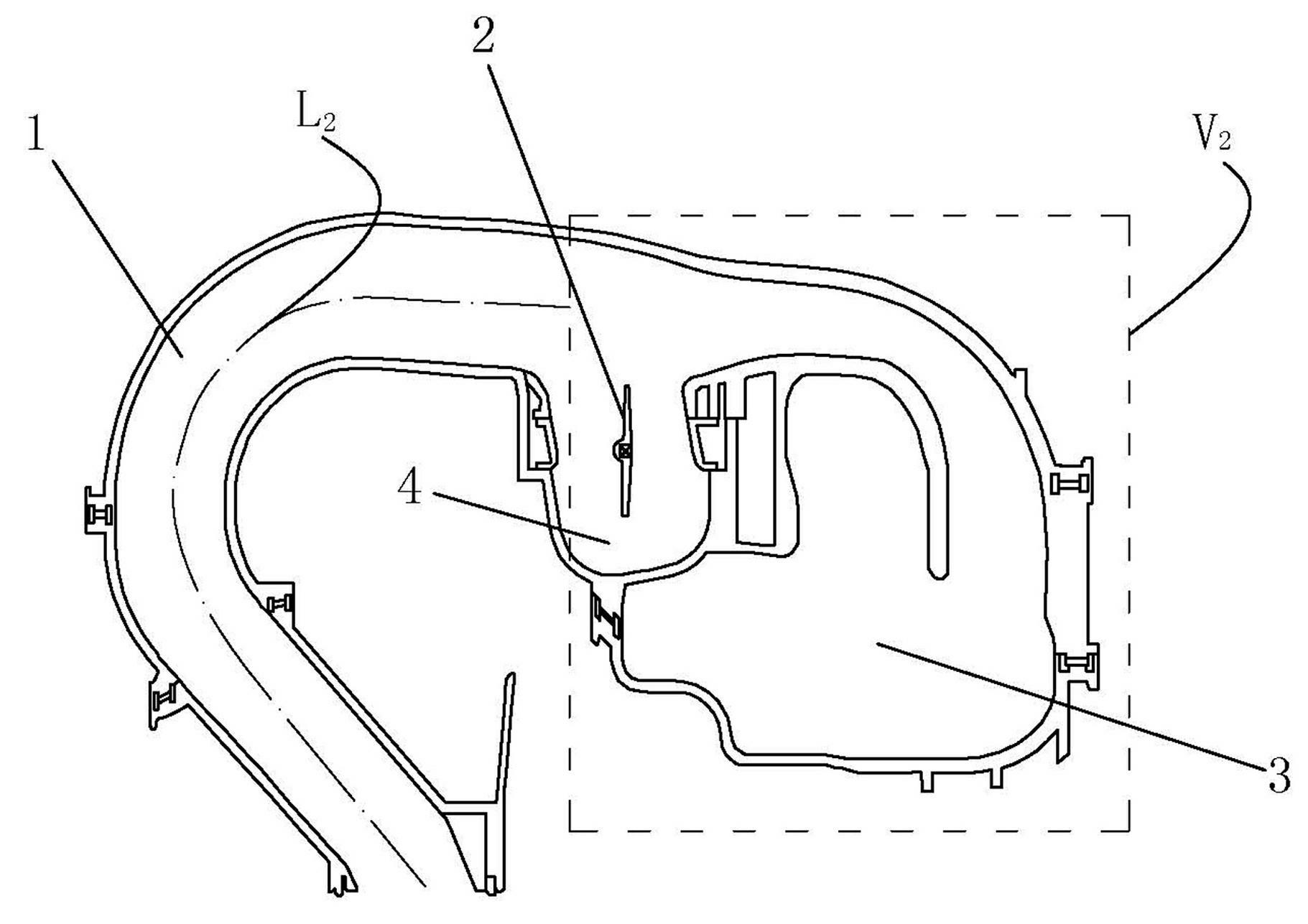

[0012] figure 1 and figure 2 A specific embodiment of the variable intake manifold of the present invention is shown, which includes a plenum chamber 3 and an air passage 1, and the intake end of the air passage 1 communicates with the plenum chamber. On the air passage 1, near the inlet end of the air passage, there is a regulating chamber 4 communicated with the air passage, and at the junction of the regulating chamber 4 and the air passage 1, a device for controlling the regulating chamber 4 is installed. The opening and closing of the valve plate 2 (the valve plate can realize the rotation of 90 degrees).

[0013] The working principle of this embodiment is as follows:

[0014] like figure 1 As shown, when the engine is running at a low speed, the valve plate 2 is in the closed position and the adjustment chamber 4 is closed (that is, the adjustment chamber is separated from the air passage), and the length of the air passage 1 at this time is longer (such as figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com