Immunological data drive control method and equipment for solving polyester industrial yarn winding system control problem

A data-driven control and data-driven technology, applied in general control systems, control/regulation systems, adaptive control, etc., can solve problems such as poor dynamic performance of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

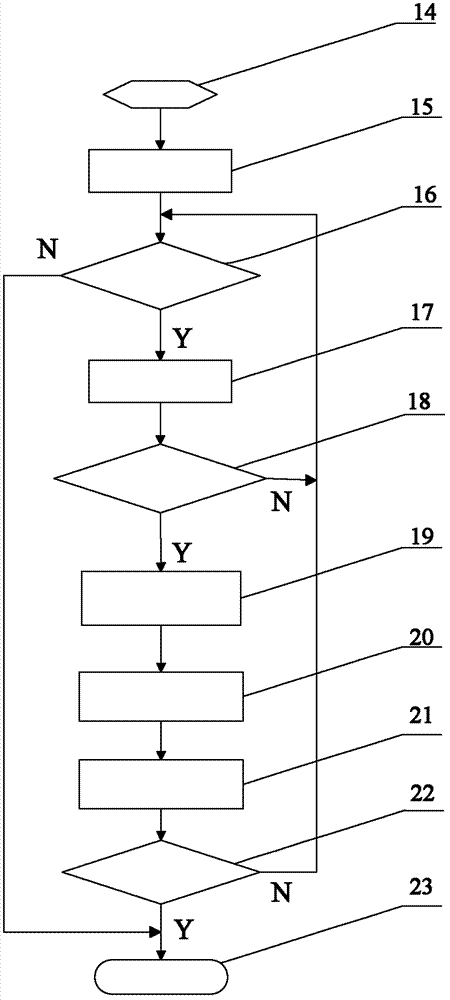

[0067] An immune data-driven control method of the present invention adopts a pseudo-removing control strategy while a conventional controller adopts a PID controller. The steps are as follows:

[0068] 1) Establish immune data-driven control link

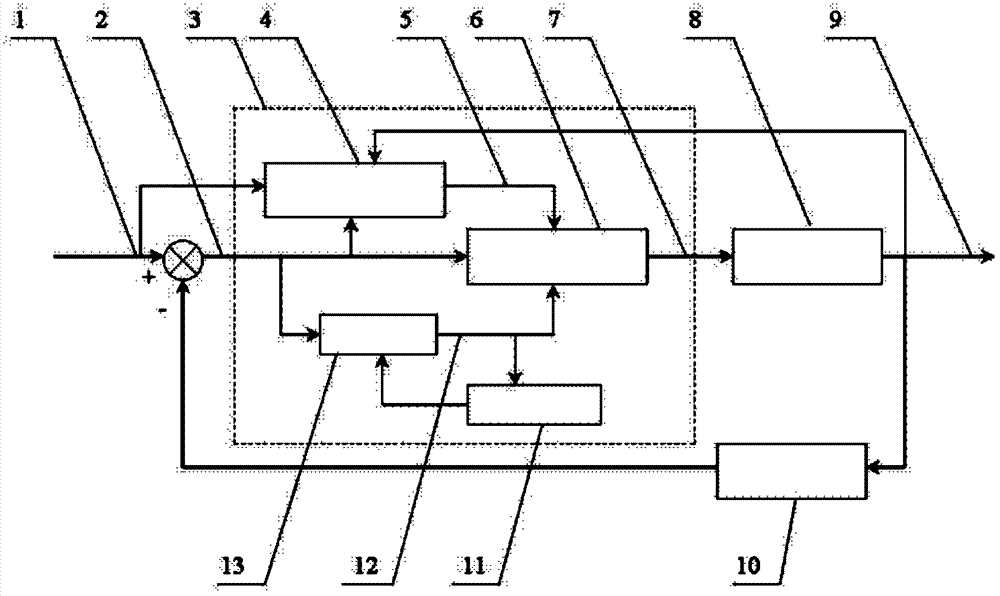

[0069] Such as figure 1As shown, the immune data-driven controller (3) includes a data-driven control unit (4), a conventional controller (6) and an immune regulation unit, wherein the immune regulation unit is composed of an immune feedback unit (11) and an immune regulation unit (13) , wherein the controlled object reference input (1) is connected to the input terminal of the data-driven control unit (4), and the output error (2) is respectively connected to the data-driven control unit (4), the conventional controller (6) and the immune regulation unit (13 ), the actual output (9) of the controlled object is connected to the input end of the data-driven control unit (4), and the output end of the data-driven control unit (4) i...

Embodiment 2

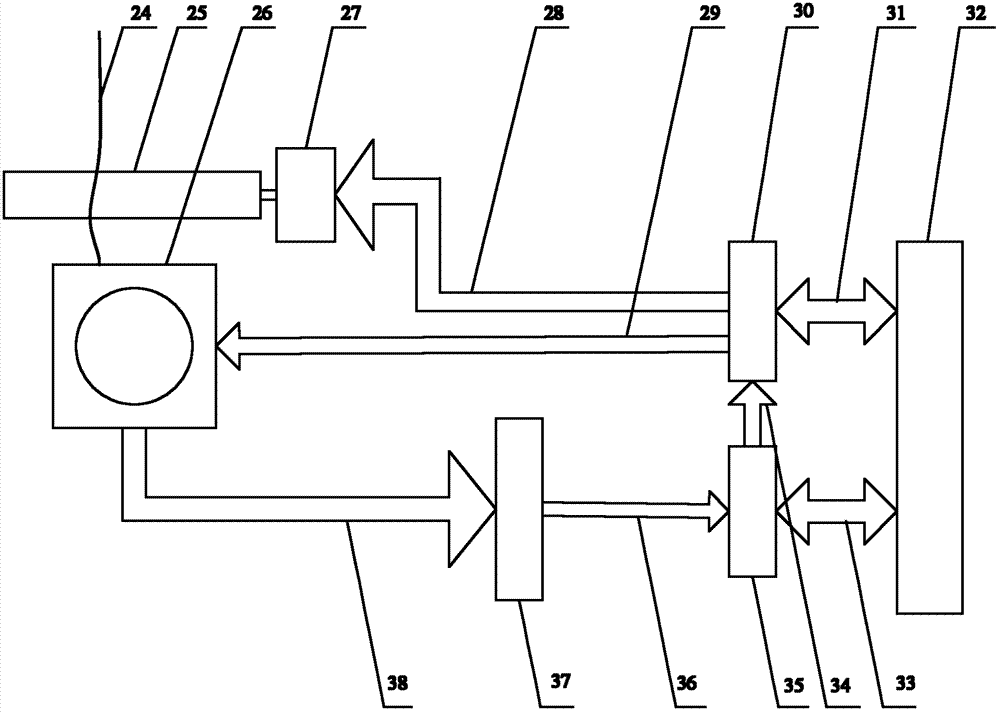

[0097] The equipment of the present invention that solves the control problem of the polyester industrial yarn winding system, such as image 3 As shown, it includes: the winding machine (26) is connected to the feedback detection module (37) through the winding system output loop (38), and is connected to the calculation module (35) through the feedback loop (36), and the calculation module (35) passes The two-way loop two (33) is connected to the upper computer (32), and the calculation module (35) is output to the immune data-driven controller module (30) through the error loop (34), and the immune data-driven controller module (30) is also passed through the two-way loop one (31) is connected to the upper computer (32), and the immune data drive controller module (30) is connected to the winding machine (26) through the output loop two (29), and is connected to the traverse control motor (27) through the output loop one (28). ), the traverse control motor (27) controls the...

Embodiment 3

[0101] An immune data-driven controller described in the present invention adopts a virtual reference feedback setting strategy while a conventional controller adopts a PID controller. The steps are as follows:

[0102] 1) Establish immune data-driven control link

[0103] Such as figure 1As shown, the immune data-driven controller (3) includes a data-driven control unit (4), a conventional controller (6) and an immune regulation unit, wherein the immune regulation unit is composed of an immune feedback unit (11) and an immune regulation unit (13) , wherein the controlled object reference input (1) is connected to the input terminal of the data-driven control unit (4), and the output error (2) is respectively connected to the data-driven control unit (4), the conventional controller (6) and the immune regulation unit (13 ), the actual output (9) of the controlled object is connected to the input end of the data-driven control unit (4), and the output end of the data-driven c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com