Anti-collision control method for gantry crane lifting trolley

A control method and technology of gantry cranes, applied in safety devices, hoisting devices, transportation and packaging, etc., can solve problems such as high driving precision requirements, heavy weight, distraction, etc., achieve a wide range of applications, solve safety problems, prevent The effect of safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

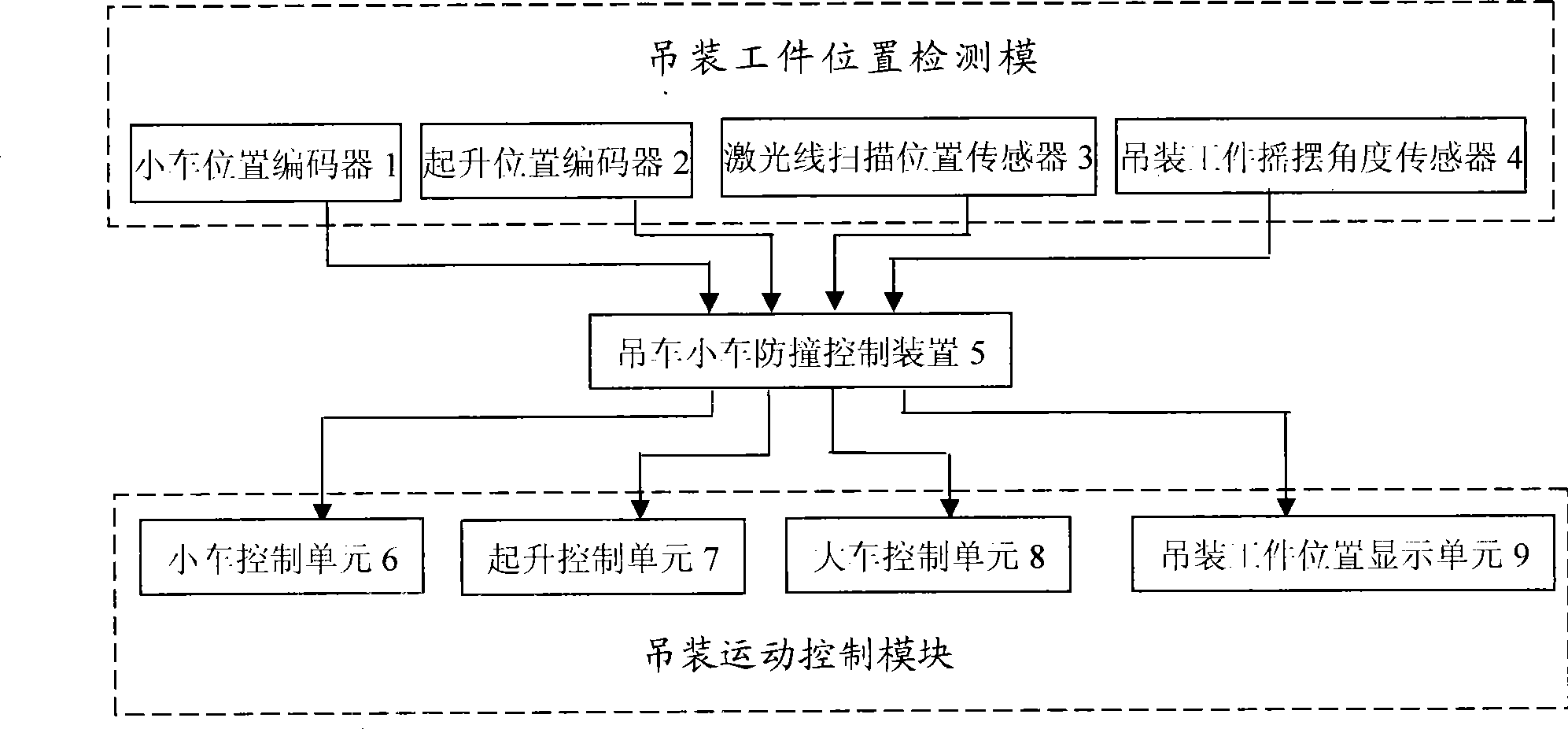

[0036] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

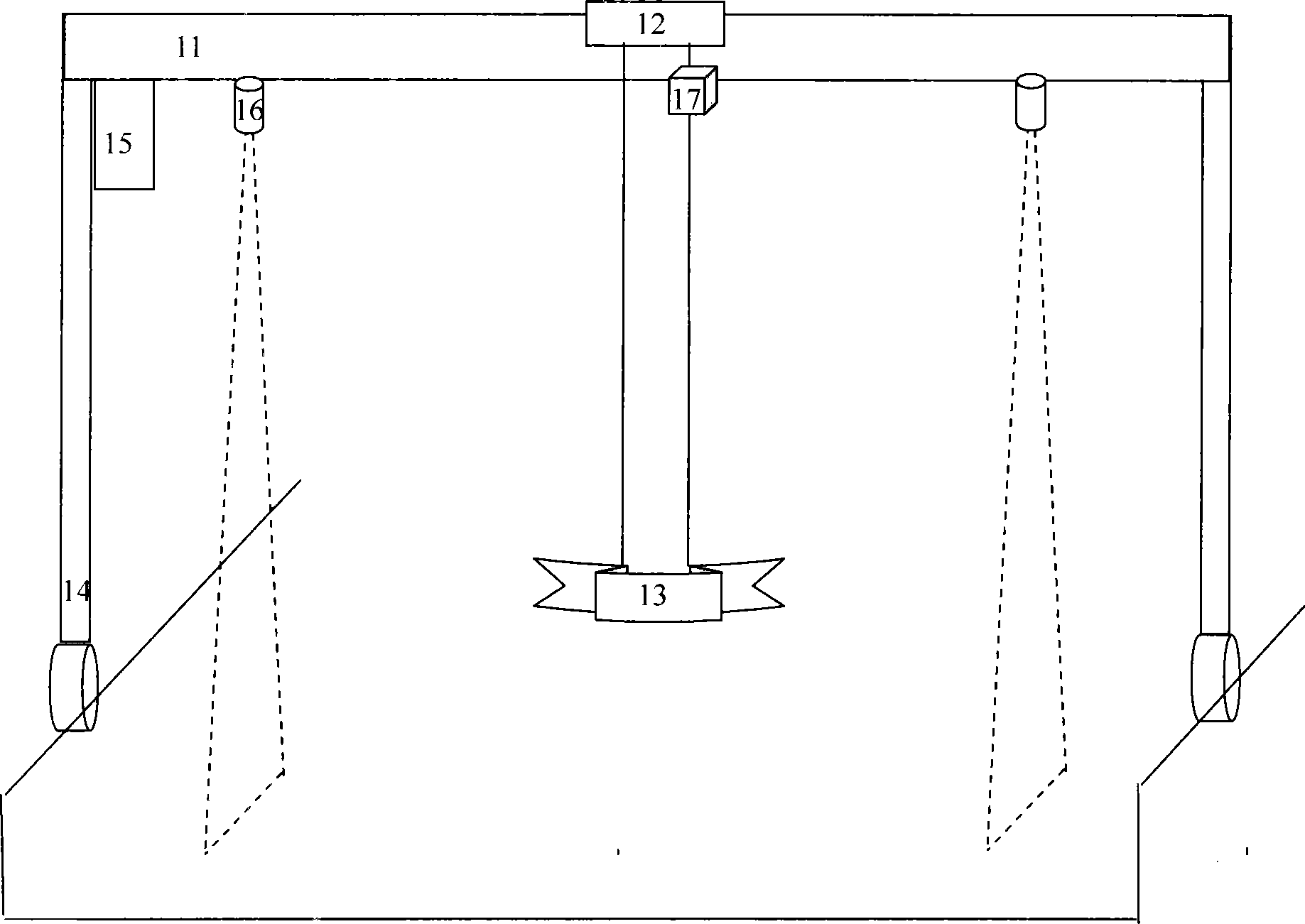

[0037] see figure 1 As shown, the hardware system based on the anti-collision control method of the gantry crane hoisting trolley of the present invention includes the anti-collision control device 5 of the trolley trolley, and also includes a position detection module for hoisting workpieces and a motion control module for hoisting, which are respectively connected with the anti-collision control device of the trolley trolley. 5 phase connections. Wherein, the hoisting motion control module of the system includes a trolley control unit 6, a lifting control unit 7, a cart control unit 8 and a hoisting workpiece position display unit 9; the hoisting workpiece position detection module of the system includes a trolley position encoder 1 , the lifting position encoder 2, the laser line scanning position sensor 3, can also further include a lift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com