A Direct Voltage Sine Wave Driving Method for Brushless DC Motor

A technology of brushless DC motor and driving method, applied in the direction of electronic commutator, torque ripple control, etc., can solve the problems of few practical projects, and achieve the effect of large starting torque, low noise and constant torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

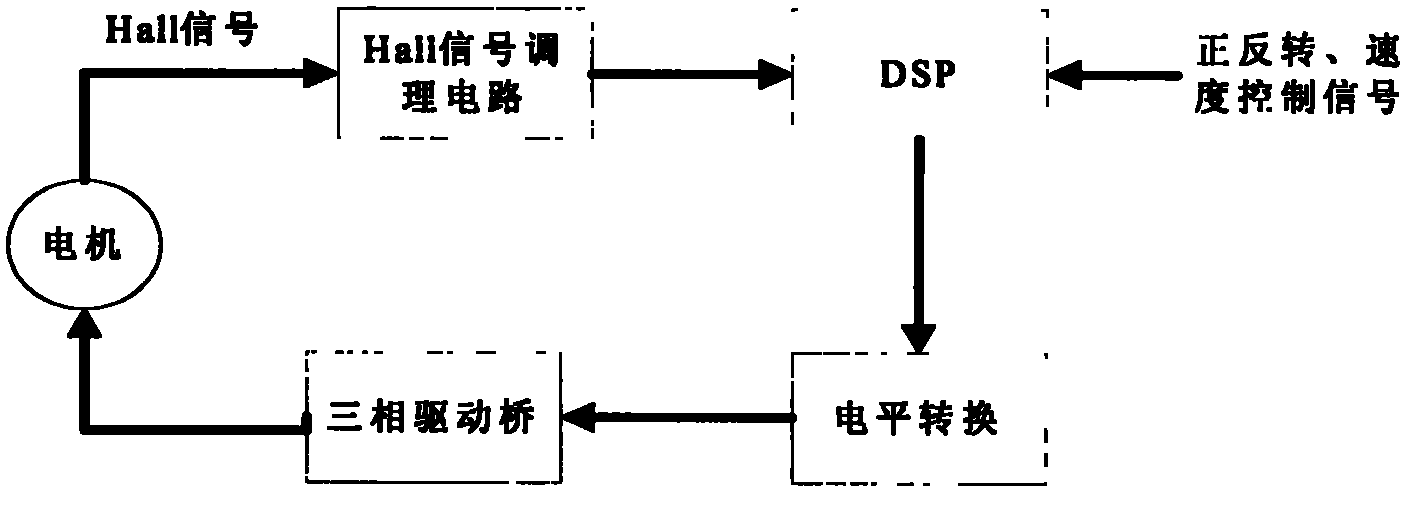

[0038] The brushless DC motor controller mainly determines the position of the motor rotor by collecting the signal of the position sensor in the motor, and realizes the commutation of the motor by controlling the on-off of the electronic commutator through the position of the motor rotor. The block diagram of the DC brushless motor control principle is as follows: figure 1 shown.

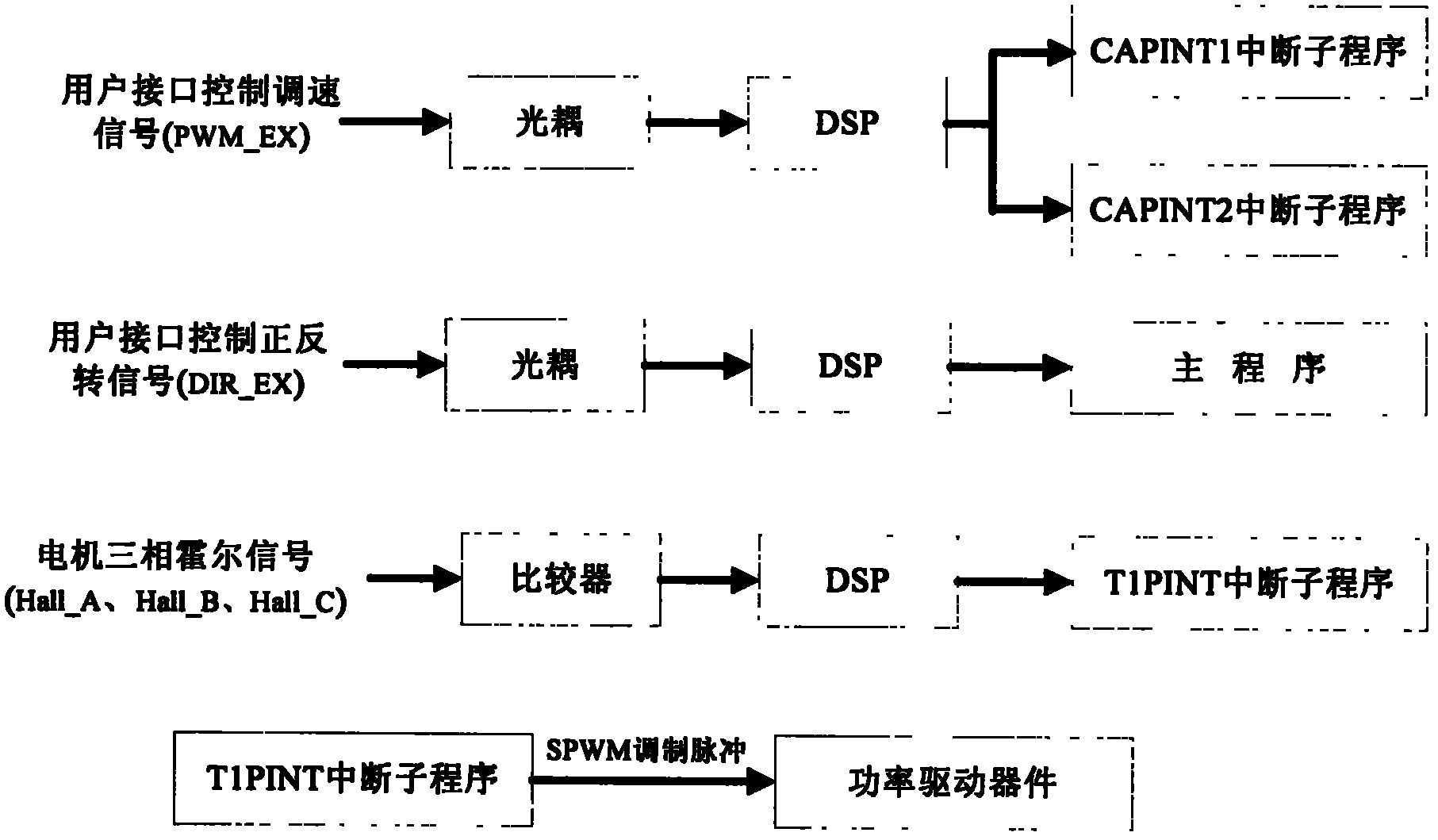

[0039] From figure 2 It can be known that the external input signal of the sine wave driver (that is, the motor three-phase Hall signal Hall_A, Hall_B, Hall_C) and the external control signal (that is, the user interface control speed signal PWM_EX, the forward and reverse signal DIR_EX) and the sine wave driver microprocessor hardware And the interface relationship between each subroutine software, so as to clarify the signals of the sine wave driver and the system software and ha...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap