Manufacturing method and manufacturing apparatus of tape-shaped reinforcing fiber base material having arc-shaped portion, and laminate, preform, and fiber-reinforced resin composite material using the base material

A technology for reinforcing fibers and fiber substrates, which is applied in the field of fiber-reinforced resin composite materials, and can solve problems such as slack and fiber wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

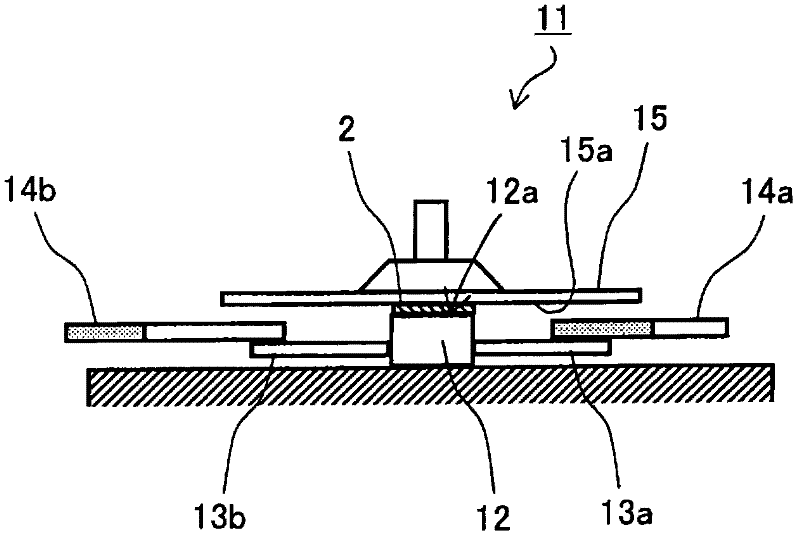

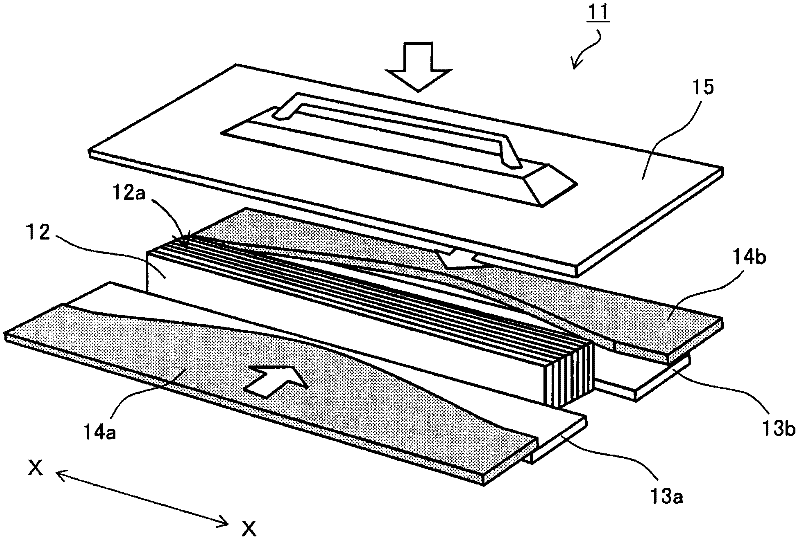

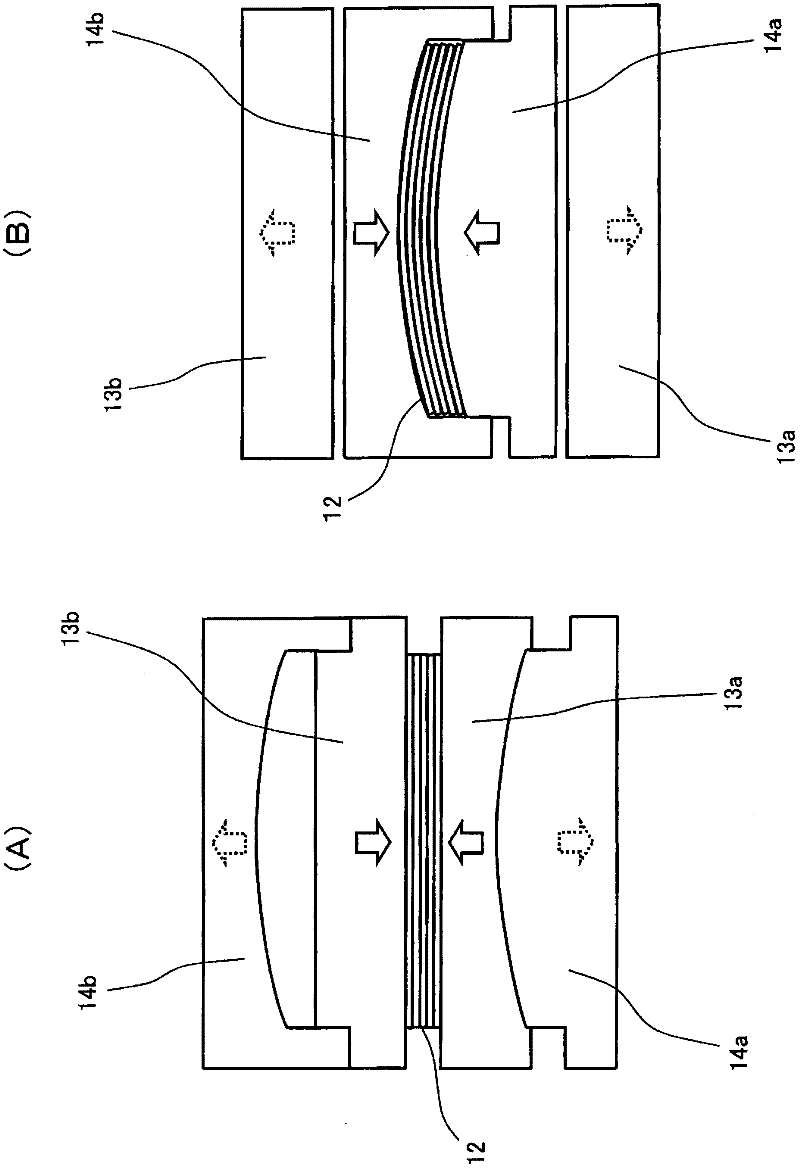

[0059] See attached below Figure 1 Preferred embodiments of the present invention will be described.

[0060] Figure 1 to Figure 5 A manufacturing apparatus and a manufacturing method thereof are shown for carrying out a method of manufacturing a tape-shaped reinforcing fiber base material having an arcuate portion according to one embodiment of the present invention. Figure 1 ~ Figure 4 The shown device is used to bend and deform at least a part of the obtained strip-shaped unidirectional reinforcing fiber substrate 2 into an arc shape (direction Y-Y of the curved shape) in the direction along the direction X-X of the substrate length, The strip-shaped unidirectional reinforcing fiber substrate 2 will be as Figure 5 The illustrated reinforcing fiber tows 1 are arranged in parallel in one direction of the base material longitudinal direction X-X. Figure 5 The illustrated base material 2 is configured as a unidirectional reinforcing fiber base material 2 in which reinfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com