Shock absorbing device of water-jet loom

A shock-absorbing device and water-jet loom technology, which is applied in looms, textiles, textiles, and papermaking, and can solve problems such as unbalanced vibration, yarn breakage, and strong vibration of water-jet looms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

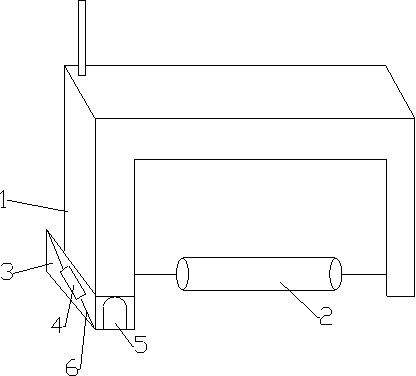

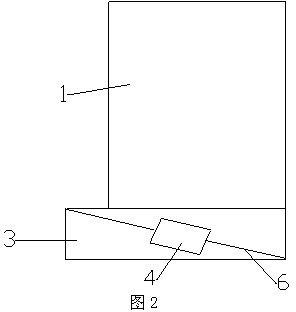

[0014] see figure 1 with figure 2 , the damping device of the water-jet loom, which is characterized in that it includes a roughly cuboid-shaped support frame 3 fixed below the frame 1, and a cloth rolling roller 2 fixed on the front of the water-jet loom (note that only the figure is shown in the figure) Cloth rolling roller 2 is installed above the cloth rolling roller 2 (not shown in the figure), and the specific structure of the water jet loom is almost not shown in the figure), and the support frame 3 is provided with inclined connecting The rod 6 and the inclined shock absorber 1 connected with the connecting rod 6, the vertical shock absorber 5 is also arranged in the support frame 3, and the shock absorber 2 5 is directly connected with the frame 1. Note that the support frame 3 must have sufficient pressure resistance to bear the weight of the entire water jet loom.

[0015] A vertical shock absorber 25 is set in the support frame 3 below the water jet loom frame ...

specific Embodiment approach 2

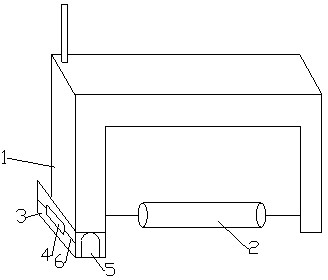

[0016] Referring to Fig. 3 and Fig. 4, the shock absorbing device of the water-jet loom is characterized in that it includes a roughly rectangular parallelepiped support frame 3 fixed under the frame 1, and a cloth rolling roller 2 fixed on the front of the water-jet loom ( Note that only the cloth rolling roller 2 is shown in the figure, and there is a cloth guide stick (not shown) above the cloth rolling roller 2, and the specific structure of the water jet loom is almost not shown in the figure), the support frame 3 A horizontal connecting rod 6 and a horizontal shock absorber 1 connected with the connecting rod 6 are arranged inside, and a vertical shock absorber 2 5 is also arranged in the support frame 3, and the shock absorber 2 5 is directly connected to the frame 1 connected. Note that the support frame 3 must have sufficient pressure resistance to bear the weight of the entire water jet loom.

[0017] A vertical shock absorber 25 is set in the support frame 3 below ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com