Permanent magnet governor with lever air gap adjustment device

A technology for permanent magnet speed governors and regulating devices, which is applied in the direction of electromechanical devices, electromechanical transmission devices, electrical components, etc., can solve problems such as difficult manufacturing, excessive wear, and difficult manufacturing of push-pull mechanisms, and achieve accurate and stable gas Gap adjustment, vibration and noise reduction, easy inspection and maintenance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

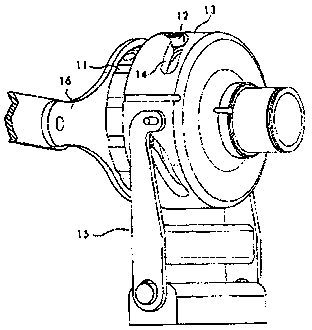

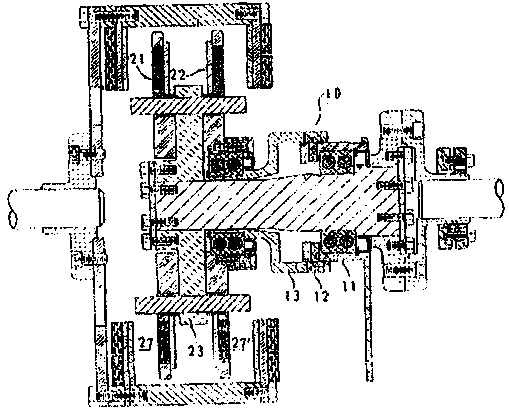

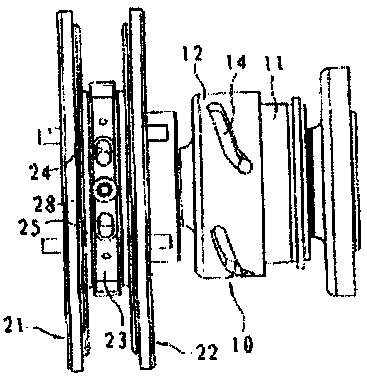

[0032] See Figure 5 , Figure 6 , is a structural schematic diagram of an embodiment of a permanent magnet governor with a lever-type air gap adjustment device in the present invention, including a conductor rotor 1, a permanent magnet rotor 2, an intermediate shaft 3 and an air gap adjustment mechanism, and the conductor rotor 1 is in phase with the conductor side hub 4 Connection, the air gap adjustment mechanism includes a linear driver 5, a lever 6 and an adjustment sleeve 7, the adjustment sleeve 7 is connected with the permanent magnet rotor 2 through the permanent magnet side hub 8, the permanent magnet side hub 8 is slidingly connected with the intermediate shaft 3, and the intermediate shaft 3 One end of the driving rod 6 is connected to the middle disc 9; one end of the driving rod 6 is a U-shaped opening, which is hinged with the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com